GB 55SiCrA/DIN 54SiCr6 Spring Steel Flat

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

,high strength and toughness

2,good hardenability and plasticity

3,excellent decarburization

55SiCrA/54SiCr6 spring steel

Quick Details:

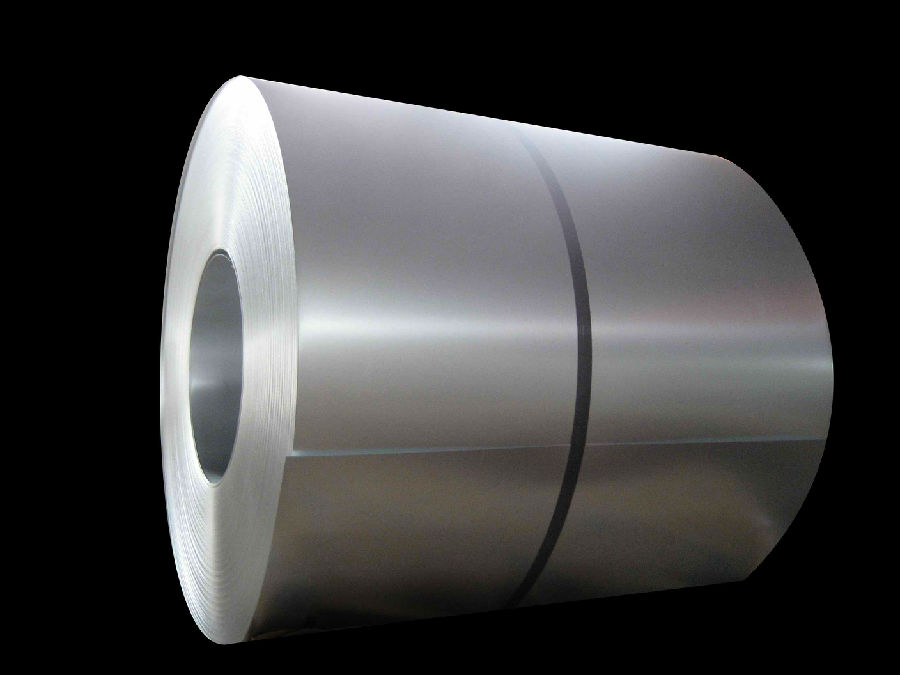

Name: GB 55SiCrA/DIN 54SiCr6 Spring Steel Flat

Place of Origin:Liaoning,China Brand Name:Dongbei Tegang

Shape:Flat Material:Spring Steel

Steel Grade: GB 55SiCrA/DIN 54SiCr6

Size:Thick: 5mm~10mm;Width: 120mm~500mm

Application: used for making oblate springwhich can bear heavy load in rolling stock and tractor industry; coiled spring which its diameter is less than 30mm; heat resisting spring .

Chemical composition

| C | Si | Mn | P | S | Cr | Ni | Cu |

| 0.51~0.59 | 1.20~1.60 | 0.50~0.80 | ≤0.025 | ≤0.025 | 0.50~0.80 | ≤0.35 | ≤0.25 |

Packing&Delivery:

Packaging details: According to customer's require or export's standard

Delivery Time: In 30days after we receive 30% deposite

Port: Dalian

MOQ: 1TON

Standard:

| ASTM | USA | Ameirican Society of Mechanical Engineers |

| AISI | USA | Acronym of American Iron and Steel Institute |

| JIS | JP | Japanese Industrial Standards |

| DIN | GER | Deutsches Institut für Normung e.V. |

| UNS | USA | Unified Numbering System |

Product Advantages:

1,high strength and toughness

2,good hardenability and plasticity

3,excellent decarburization

- Q: What are the different methods of surface texturing for special steel?

- There are several different methods of surface texturing for special steel, each with its own unique advantages and applications. Some of the most common methods include: 1. Shot blasting: This process involves propelling small metal or ceramic particles at high speeds onto the surface of the steel. It removes any impurities or contaminants on the surface, creating a textured finish that improves adhesion for coatings and paints. 2. Acid etching: This method involves immersing the steel in an acidic solution, which selectively removes a thin layer of the surface to create a textured pattern. Acid etching can be used to achieve intricate designs or patterns on the steel surface. 3. Mechanical grinding: This technique involves using abrasive tools to physically grind and remove material from the surface of the steel. It can be used to create a range of textures, from smooth to rough, depending on the grit size of the grinding tool. 4. Laser texturing: This advanced method uses laser technology to create precise and intricate patterns on the surface of the steel. Laser texturing offers high precision and repeatability and can be used to achieve complex designs that are difficult to achieve with other methods. 5. Electrochemical etching: This process involves using an electric current to selectively dissolve the surface of the steel, creating a textured pattern. It can be used to achieve consistent and controlled textures on the steel surface. Each method of surface texturing has its own advantages and limitations, and the choice of method depends on the desired texture, the specific properties of the special steel, and the intended application.

- Q: How is special steel used in the production of bearings?

- Special steel is used in the production of bearings due to its high strength, durability, and resistance to wear and corrosion. The use of special steel ensures that bearings can withstand heavy loads, high speeds, and harsh operating conditions, providing smooth and reliable performance. The steel used in bearings is carefully engineered to have specific properties, such as hardness and toughness, which are essential for their effective functioning.

- Q: What are the specific requirements for special steel used in the marine shafting industry?

- The specific requirements for special steel used in the marine shafting industry include high strength, excellent corrosion resistance, and good weldability. The steel must also have good fatigue resistance to withstand the constant loading and vibrations experienced in marine environments. Additionally, it should have low magnetic permeability to minimize interference with navigation systems.

- Q: What are the future trends in special steel manufacturing?

- Some of the future trends in special steel manufacturing include advancements in technology and automation, increased focus on sustainability and environmental impact, development of new alloys and materials with enhanced properties, and growing demand for specialized steels in industries like aerospace, automotive, and renewable energy. Additionally, there is a shift towards customization and tailored solutions to meet specific customer requirements, as well as an emphasis on research and development to drive innovation in the field.

- Q: How does special steel contribute to the power generation equipment industry?

- Enhanced performance, durability, and reliability are crucial contributions of special steel to the power generation equipment industry. Turbines, generators, and transformers, which operate in harsh conditions characterized by high temperatures, pressure, and corrosive environments, benefit from the unique properties and characteristics of special steel. An advantage of special steel in power generation equipment lies in its capacity to withstand high temperatures. Heat-resistant steel alloys, explicitly designed for extreme conditions, enable power plants to function efficiently and safely at elevated temperatures. These steels maintain their strength, structural integrity, and resistance to creep and fatigue even under the highest operating temperatures, guaranteeing the reliability and longevity of the equipment. Moreover, special steel exhibits excellent corrosion resistance, a critical feature for power generation equipment due to the presence of corrosive elements like water, steam, and chemicals. Stainless steel, in particular, is highly utilized in power plants thanks to its remarkable corrosion resistance, preventing equipment degradation and reducing maintenance costs. By employing special steel, power generation companies can minimize downtime and improve overall efficiency. Furthermore, special steel contributes significantly to the power generation equipment industry by providing exceptional strength and mechanical properties. This is especially crucial for large-scale equipment like turbines and generators, which face high mechanical loads. High-strength special steel allows these components to withstand stress and pressure, ensuring their safe and reliable operation over extended periods. Additionally, special steel's unique properties, such as high hardness and wear resistance, make it suitable for critical components like blades and rotors, minimizing the risk of failure and enhancing overall performance. In conclusion, special steel is an indispensable material within the power generation equipment industry. Its ability to endure high temperatures, resist corrosion, and provide exceptional strength and mechanical properties ensures the reliability, durability, and efficiency of power plants. Through the utilization of special steel, power generation companies can enhance equipment performance and reduce maintenance costs, ultimately contributing to the sustainable and dependable production of electricity.

- Q: How does special steel perform in high-temperature corrosion resistance?

- Special steel typically performs well in high-temperature corrosion resistance due to its unique composition and properties. It is specifically designed to withstand the harsh conditions of high temperatures and corrosive environments. The alloying elements in special steel, such as chromium, nickel, and molybdenum, enhance its resistance to corrosion and oxidation at elevated temperatures. Additionally, the steel's microstructure and heat treatment play a crucial role in improving its high-temperature corrosion resistance. Overall, special steel exhibits excellent performance in protecting against corrosion and maintaining its structural integrity in high-temperature environments.

- Q: How does special steel contribute to the automotive aftermarket?

- Special steel plays a significant role in the automotive aftermarket by contributing to the development and enhancement of various automotive components. This high-quality steel is specifically engineered to possess exceptional strength, durability, and resistance to wear and tear. One of the primary ways special steel contributes to the automotive aftermarket is through the production of performance parts. These parts are designed to improve the performance and efficiency of vehicles, catering to the needs and preferences of car enthusiasts. For example, special steel is used in the manufacturing of exhaust systems, turbochargers, and intake manifolds, allowing for increased horsepower and torque, as well as improved fuel efficiency. Additionally, special steel is utilized in the production of suspension components, such as coil springs and sway bars, which provide superior handling and stability. These components not only enhance the driving experience but also ensure the safety of the vehicle and its occupants. Furthermore, special steel is instrumental in the manufacturing of braking systems, including rotors and brake calipers. These components are crucial for effective braking and maintaining control over the vehicle. By utilizing special steel, aftermarket brake systems can offer improved stopping power, reduced fade, and increased resistance to high temperatures. Moreover, special steel is employed in the production of engine components, such as crankshafts, connecting rods, and valve springs. These components are subjected to extreme forces and temperatures, and special steel's exceptional strength and heat resistance enable them to withstand such conditions, resulting in improved engine performance and longevity. In summary, special steel plays a vital role in the automotive aftermarket by contributing to the development of high-performance parts, suspension components, braking systems, and engine components. Its superior strength, durability, and resistance to wear and tear ensure improved vehicle performance, efficiency, and overall driving experience.

- Q: How does special steel perform in high-speed applications?

- Special steel is specifically designed to perform exceptionally well in high-speed applications. Its unique composition and manufacturing process make it highly resistant to heat, wear, and fatigue, allowing it to withstand the extreme conditions often encountered in high-speed operations. One of the key properties of special steel that makes it ideal for high-speed applications is its high strength-to-weight ratio. This means that it can maintain its structural integrity and withstand heavy loads while being lightweight, enabling it to efficiently handle the demands of high-speed operations. Additionally, special steel possesses excellent heat resistance, which is crucial in high-speed applications where temperatures can rise significantly. It has a high melting point and can maintain its strength and hardness even at elevated temperatures, preventing deformations or failures that could occur with other materials. Furthermore, special steel's exceptional wear resistance ensures long-lasting performance in high-speed applications. It is able to withstand the continuous friction and abrasive forces that occur at high speeds, reducing the need for frequent replacements and improving overall efficiency. Moreover, special steel's resistance to fatigue is another important factor in its performance in high-speed applications. It can withstand repetitive loading and cyclic stresses without developing cracks or fractures, ensuring a longer service life and minimizing the risk of sudden failures. In summary, special steel is specifically engineered to excel in high-speed applications. Its high strength-to-weight ratio, heat resistance, wear resistance, and fatigue resistance make it an ideal choice for industries such as aerospace, automotive, and manufacturing, where high-speed operations are common. Its superior performance in these applications ensures reliable and efficient performance, contributing to enhanced productivity and safety.

- Q: How does special steel contribute to the strength of structures?

- Special steel contributes to the strength of structures through its unique properties and composition. It is specifically engineered to have higher tensile strength, durability, and resistance to corrosion compared to regular steel. Its increased strength allows structures to withstand heavier loads, vibrations, and extreme weather conditions more effectively, ensuring their stability and longevity. Additionally, the use of special steel enables the construction of lighter and more streamlined structures, as thinner sections can be used without compromising their strength. Overall, special steel plays a vital role in enhancing the structural integrity and safety of various buildings, bridges, and infrastructure projects.

- Q: What are the main characteristics of pressure vessel steel forgings?

- The main characteristics of pressure vessel steel forgings include high strength, excellent durability, enhanced resistance to corrosion and wear, and the ability to withstand high pressure and temperature conditions. These forgings are typically made from low-alloy or carbon steel and undergo a forging process to improve their mechanical properties and ensure uniformity. Additionally, pressure vessel steel forgings are extensively tested for quality assurance to ensure their reliability and safety in various industrial applications.

Send your message to us

GB 55SiCrA/DIN 54SiCr6 Spring Steel Flat

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords