Galvanized welded steel pipe for any materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1、Structure of Galvanized welded steel pipe for materials :

The surface of galvanized steel pipe welded steel pipe of hot dip galvanized layer or. Galvanized can increase the corrosion resistance of the steel tube, prolong service life. Galvanized pipe is widely used, in addition to water, gas, oil and other general low pressure fluid pipelines. It is also used in the petroleum industry, especially for offshore oil field of oil well pipe and oil pipe, chemical, coking equipment of oil heater, condensation cooler, coal run oil exchanger tube, and trestle pile, the mine tunnel support frame tube.

2、Main Features of Galvanized welded steel pipe for building materials :

• High manufacturing accuracy

• High strength

• Good visual effect

• Reasonable price

3、 Galvanized welded steel pipe for building materials Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 1 - 33 mm |

Section Shape | Round |

Outer Diameter | 21 - 610mm |

Place of Origin | Tianjin, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:Q195 Q235 Q345 X42 X52

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Galvanized welded steel pipe for building materials :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

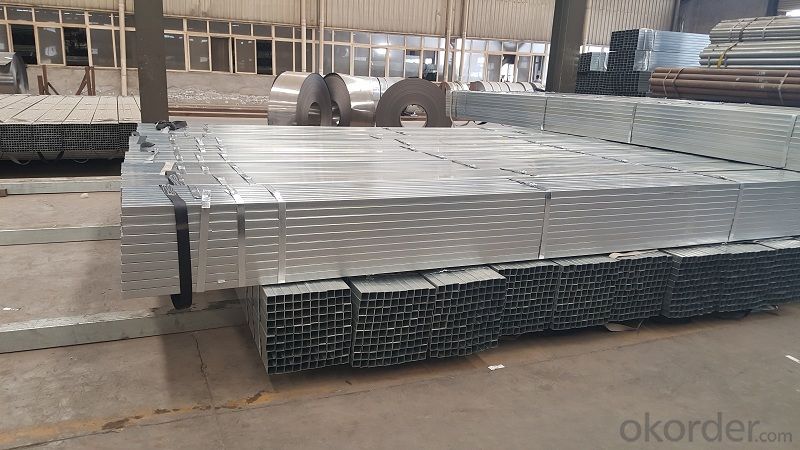

6、 Galvanized welded steel pipe for building materials Images:

- Q: What are the specific differences between flexible pipes and rigid pipes?

- Choose from the waterproof performance:A rigid waterproof sleeve is a steel pipe with an outer wing (a steel ring made of a steel ring), mounted in the wall (mostly concrete walls), used for general pipe wall crossing, and is beneficial to the waterproof of the wall;The flexible waterproof casing except external wing ring, flange ring and internal wire like, and have complete sets sold, but also their own processing, for pipeline damping needs, such as pipes and pumps connected through walls.

- Q: Can steel pipes be used for sewage treatment plants?

- Yes, steel pipes can be used for sewage treatment plants. Steel pipes are durable and resistant to corrosion, making them ideal for handling sewage and wastewater in such facilities. They are commonly used for conveying and distributing sewage, as well as for constructing various components like pipelines, pump stations, and treatment tanks. Additionally, steel pipes can withstand high pressure and are available in various sizes, making them suitable for the diverse needs of sewage treatment plants.

- Q: How do you determine the wall thickness of a steel pipe?

- The wall thickness of a steel pipe can be determined by measuring the outer diameter (OD) and the inner diameter (ID) of the pipe, and then subtracting the ID from the OD.

- Q: What are the different manufacturing standards for steel pipes?

- There are several different manufacturing standards for steel pipes, including American Society for Testing and Materials (ASTM), International Organization for Standardization (ISO), and American Petroleum Institute (API). These standards outline the requirements for various aspects of steel pipe manufacturing such as dimensions, material composition, mechanical properties, and testing procedures. Compliance with these standards ensures that steel pipes meet the necessary quality and performance requirements for their intended applications.

- Q: What does "SC50" steel pipe mean in civil engineering?

- Welded steel pipe refers to the use of steel or steel plate bending deformation into a round, square and other shapes after welding into the surface of the joint of the steel pipe. The blank used in welded steel pipe is steel or strip steel.

- Q: What are the different types of steel pipe tees?

- Various plumbing and piping applications commonly utilize different types of steel pipe tees. These tees serve various purposes and offer specific functionalities. 1. Equal tee: This tee consists of three branches of the same size, ensuring an equal flow of fluid or gas through each branch. 2. Unequal tee: As suggested by its name, an unequal tee features branches of varying sizes. This allows for merging or diversion of flows with different volumes or pressures. 3. Reducing tee: This tee is deployed when the branch size is smaller than the main pipe size. It enables a reduction in size while maintaining the flow in the main line. 4. Barred tee: In situations involving the insertion or removal of a pipeline-cleaning and inspection device known as a pig, a barred tee is employed. It possesses a bar welded across one or two branches to create a bypass for the pig. 5. Lateral tee: A lateral tee has a branch angle of either 45 degrees or 90 degrees, facilitating the perpendicular alignment of the branch line with the main line. It finds extensive use in fire sprinkler systems and scenarios necessitating a change in direction. 6. Compression tee: This tee is suitable for gas or hydraulic systems, where branches are connected using compression fittings rather than welding or threading. 7. Butt-weld tee: High-pressure and high-temperature applications employ butt-weld tees. These tees are welded to the main pipe using butt-welding techniques, ensuring a robust and leak-proof connection. These represent some of the most prevalent types of steel pipe tees employed across diverse industries. The selection of the appropriate tee depends on specific project requirements, such as pipe size, flow rates, and transported materials.

- Q: Can steel pipes be painted or coated?

- Yes, steel pipes can be painted or coated. Painting or coating steel pipes is a common practice to protect them from corrosion, improve their appearance, or to meet specific industry requirements. The process involves cleaning the pipes to remove dirt, grease, and rust, followed by applying a primer and then the desired paint or coating. The choice of paint or coating depends on the intended use of the pipes. For example, epoxy coatings are often used for water or wastewater pipelines, while high-temperature resistant coatings are applied to pipes used in industrial settings. Overall, painting or coating steel pipes can enhance their durability and performance.

- Q: Is the diameter of the steel tube indicated by the outer diameter by the wall thickness or by the inside diameter by the wall thickness?

- For seamless steel pipes or nonferrous metal pipes, the outer diameter * wall thickness shall be marked".For example, 108 x 4 phi, Phi can be omitted. Some steel tubes in China, ISO and Japan adopt wall thickness to indicate the thickness of steel pipe. The method for the specification of such steel tubes is pipe outer diameter * wall thickness. For example, Phi 60.5 * 3.8.

- Q: Can steel pipes be used for underground chemical pipelines?

- Indeed, underground chemical pipelines can utilize steel pipes. The chemical industry, among other industries, extensively employs steel pipes owing to their robustness, potency, and resistance to corrosion. To ensure suitability for underground chemical pipelines, it is crucial to select an appropriate steel grade that can withstand corrosion from the specific chemicals being transported. Furthermore, the resistance of steel pipes to chemical corrosion can be further augmented through the implementation of suitable coating and lining techniques. Regular inspection and maintenance are imperative to guarantee the integrity and safety of the underground chemical pipeline system.

- Q: What are the different types of steel pipe connections for fire sprinkler systems?

- There are several types of steel pipe connections commonly used in fire sprinkler systems, including threaded connections, grooved connections, and welded connections. Threaded connections involve screwing the pipes together using tapered threads and are commonly used for smaller pipe sizes. Grooved connections use a coupling and gasket system to join the pipes, creating a secure and flexible connection. Welded connections involve permanently joining the pipes together using heat and are typically used for larger pipe sizes or in situations where maximum strength is required.

Send your message to us

Galvanized welded steel pipe for any materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords