Galvanized Structural Steel Profiles China Supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

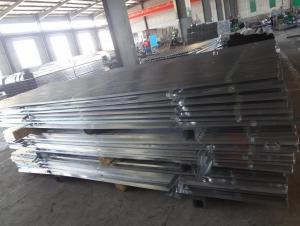

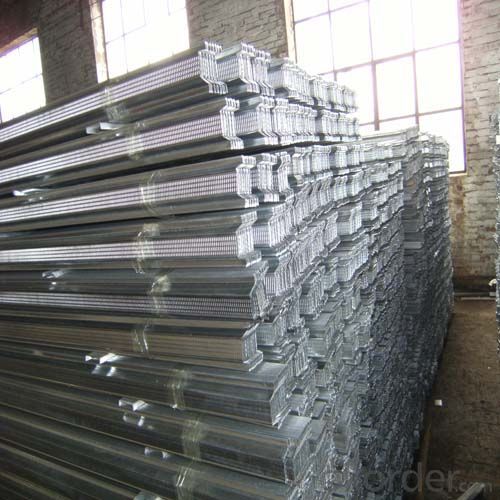

The products are made of galvanized strips with good rust-Proof function, and they are seen in hotels, theaters, factories, houses, emporiums, offices, airplane-terminal buildings, bus stations, etc..

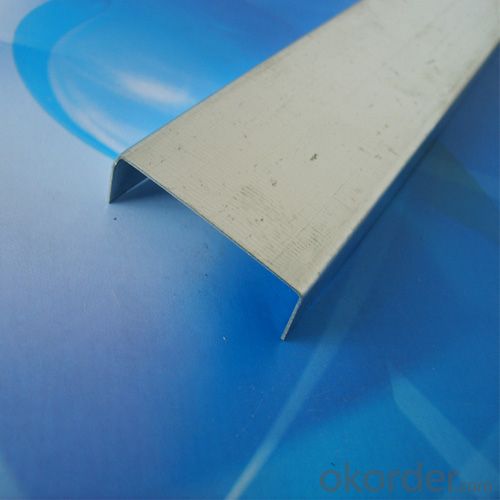

C metal stud is faced with plasterboard

U metal track is installed along the floor to fix metal stud

Specification

Item | Specification (mm) | |

Width | Height | |

V channel | 30/38 | |

Main channel | 38 | 10/12/14 |

Main channel | 50 | 12/15 |

Cross channel | 50 | 15/17/19 |

Cross channel | 60 | 27 |

Cross channel | 38 | 27 |

Furring channel | 35 | 22 |

U angle | 29 | 24/29 |

L angle | 22-35 | |

Track /Horizontal Channel | QU/UW | 50/75/100x35/40/50x0.45mm |

Stud/Vertical Channel | QC/CW | 50/75/100x35/40/50x0.45mm |

Omega Furring Channel | Ω | 35x22x12/13mm |

Product Overviews

Feature

1. Galvanized drywall metal profile raw material is high quality cold roll steel coil, strictly quality control make sure high quality product.

2. Hot dipped zinc galvanized drywall metal profile zinc coating is 80-180g/m2.

3. Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirments.

5. Advanced equipment can make sure exactly size, high quality products.

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: The room to remove the partition, can not retain the original light steel keel gypsum board ceiling?

- The room to remove the partition, you can retain the original light steel keel gypsum board ceiling.

- Q: Light steel keel gypsum board wall height is how to determine

- D = <l 240 Parameter Description: d: Maximum deformation of the component under uniform load, unit mmq: Uniform load, unit Pa, test In the composition of the material, the cross-sectional nature of the wall stiffness coefficient: EI value of the test to determine the length of the wall The use of 15mm plate instead of 12.5mm plate, the wall stiffness EI can be increased by 33% 2. The keel spacing from 600mm to 400mm, wall EI value increased by 50% 3. The keel spacing reduced from 400mm to 300mm, the wall EI value increased by 50% 4. keel on the wall than the non-buckle wall, EI value increased by 60% 5. Use type I keel than the use of C-keel, EI value increased by at least 100%. The effect of thickness on the EI value is very small relative to several other factors, EI is called bending stiffness, 75 keel spacing is 400, double-sided single layer 12mm gypsum board wall EI = 4.6 × 1010 according to the actual test EI value of the structural partition system: (unit: N.mm2, 1010)

- Q: To warm the above has been tiled, with light steel keel to build a wall, how to fix the keel?

- With a hammer to drill the ground hole can be fixed to the ground. With glue, it is certainly impossible to nail

- Q: Light steel keel wall and wood which low cost

- Should be a wooden keel, the general family decoration with a wooden keel on it, wood keel cost is low, to meet the family use, light steel keel cost high, but high strength. It is recommended to use wood keel

- Q: Use light steel keel to do the shelf, install the glass partition wall, this process is feasible? How about construction?

- Have to do, nothing can not, but not a good idea. The feeling of the glass is bright and transparent. Light steel keel specifically suitable for installation, the concealed keel with transparent glass display will be what effect.

- Q: Do light steel keel gypsum board partition to pay attention to what matters?

- 1, the main structure is completed, before the ceiling, the first wall construction. 2, light steel keel installation is completed, should be based on the construction acceptance of the keel for acceptance, such as skeleton does not meet the requirements, should be promptly adjusted. 3, the installation of gypsum board must be stress-free installation, first with self-tapping nail fixed gypsum board center parts, and then fixed the edge, so that the gypsum board after installation without any stress.

- Q: Light steel keel partition wall construction process is what

- Light steel keel partition wall - → installation of the door hole box - → installation along the top keel and along the keel → vertical keel sub-file - → installation of vertical keel - → installation of horizontal keel card - → installation panel - Sewing practice - → face layer putty paint (or paint).

- Q: Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- The practice is to first play on the ground and shed on the corner keel must be vertical after the installation of the main keel times the keel installed in the plaster board plaster brush latex paint difference is stronger than the keel cost is higher than the wood keel

- Q: Wood keel can be used to ceiling, can be used to do the wall? Light steel keel can be used in what place?

- Many temporary buildings will use wood keel to do with the wall, light steel keel more for long-term construction

- Q: Gypsum board wall is generally done to the height of the original roof or do the height of the ceiling?

- With the requirements of the party, both methods are to do, to sound or privacy is good point, then we must be separated from the top, to save money and then save money on the next day it can be on the next day.

Send your message to us

Galvanized Structural Steel Profiles China Supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords