Galvanized Steel Strip with High Quality-SGCC 680*1.0mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

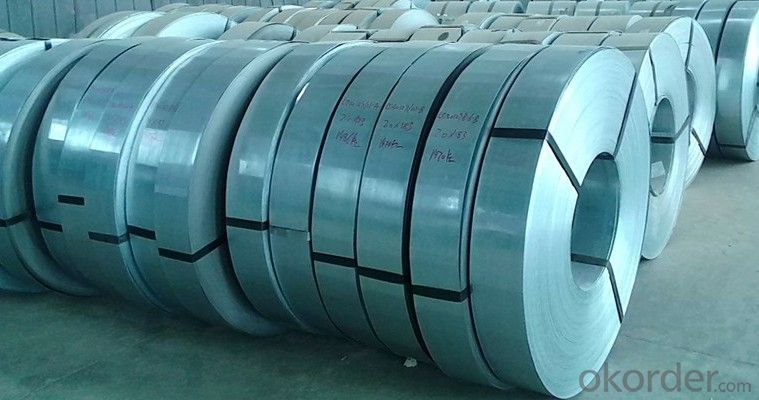

Galvanized Steel Strip with High Quality-SGCC 680*1.0mm

Product Description:

Specifications:

Thickness: 1.0mm

Width: 680mm

Material: SGCC

ID: 508mm or 610mm

Spangle: Regular spangle or zero spangle

others: chromated or no chromated; oiled or no oiled.

Advantages of Galvanized Steel Strip with High Quality-SGCC 680*1.0mm:

1. Uniform coating;

2. Strong adhesion;

3. Strong corrosion resistant ability

Usage of Galvanized Steel Strip with High Quality-SGCC 680*1.0mm:

1. Making pipes, like Greenhouse tubes, drinking water pipe, heating pipe, gas pipe and so on;

2. Used in automobile;

3. Used in construction;

4. Used in agriculture, fishery and so on.

FAQ of Galvanized Steel Strip with High Quality-SGCC 680*1.0mm:

Q1: How soon can we receive the product after purchasement?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically one month-two months.

Q2: How do you guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: The prices are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

Images of Galvanized Steel Strip with High Quality-SGCC 680*1.0mm:

*If you would like to get our price, please kindly inform us the standard/material, specifications and quantity. Thank you very much for your attention.

- Q: What is the typical fatigue strength of steel strips?

- The typical fatigue strength of steel strips can vary depending on various factors such as the specific grade of steel, heat treatment, surface finish, and dimensions of the strips. However, for most common steels, the fatigue strength typically ranges between 0.5 and 0.7 times the ultimate tensile strength of the material.

- Q: What are the different heat treatments applied to steel strips?

- There are several heat treatments applied to steel strips, including annealing, tempering, quenching, and normalizing.

- Q: How are steel strips inspected for defects?

- Steel strips are inspected for defects using various methods to ensure their quality and integrity. One common method is visual inspection, where trained inspectors visually examine the surface of the steel strips for any visible defects such as cracks, scratches, or deformities. This is often done with the help of magnifying glasses or microscopes to detect even the smallest imperfections. Another method used for defect inspection is magnetic particle testing. In this technique, the steel strips are magnetized, and fine iron particles are applied to the surface. These particles will accumulate at any areas where there are defects, allowing the inspectors to easily identify and locate them. Ultrasonic testing is also employed to inspect steel strips for defects. Ultrasonic waves are directed into the steel, and the reflections or echoes of these waves are analyzed. Any changes or irregularities in the echo pattern can indicate the presence of defects within the steel strips. In addition, eddy current testing is commonly used for defect detection in steel strips. This method involves passing an alternating current through a coil, which creates a magnetic field. When the steel strip is placed near the coil, any defects or variations in the material will cause changes in the eddy currents, which can be detected and analyzed. Furthermore, X-ray or gamma-ray testing may be utilized for defect inspection. These methods involve passing radiation through the steel strips and capturing the resulting image on a film or digital detector. Any defects, such as internal cracks or voids, will appear as dark spots on the image, making them easily identifiable. Overall, steel strips undergo a combination of visual, magnetic particle, ultrasonic, eddy current, and radiographic inspections to ensure that they are free from defects and meet the required quality standards. These rigorous inspection methods help to ensure the reliability and safety of steel strips in various industries.

- Q: How are steel strips used in the packaging industry?

- Steel strips are commonly used in the packaging industry to secure and reinforce packaging materials such as boxes, pallets, and bundles. They provide strength and stability during transportation and storage, ensuring that the packaged goods remain intact and protected.

- Q: How are steel strips heat-treated for specific applications?

- Steel strips are heat-treated for specific applications by subjecting them to controlled heating and cooling processes. This involves heating the steel strips to a specific temperature and holding it there for a predetermined amount of time. The strips are then rapidly cooled, or quenched, to achieve the desired hardness, strength, or other mechanical properties. The heat treatment process can also involve tempering or annealing to further refine the steel's properties. Overall, the goal is to tailor the steel strips' microstructure to meet the specific requirements of the intended application.

- Q: Are steel strips suitable for construction purposes?

- Yes, steel strips are suitable for construction purposes. Steel strips are strong, durable, and resistant to corrosion, making them an excellent choice for various construction applications such as framing, support structures, and reinforcement. They provide stability and structural integrity to buildings and can withstand heavy loads, making them ideal for construction purposes.

- Q: What are the safety precautions when working with steel strips?

- When working with steel strips, it is important to follow several safety precautions to minimize risks. Firstly, wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots is crucial to protect against cuts, burns, and potential eye injuries. Additionally, workers should ensure a well-ventilated workspace to prevent inhalation of harmful fumes or dust particles generated during cutting or shaping processes. It is also essential to handle steel strips with caution, using proper lifting techniques and avoiding sharp edges to prevent accidents. Regular maintenance and inspection of tools and equipment should be conducted to ensure their proper functioning, reducing the risk of accidents. Lastly, proper training and adherence to safety protocols are vital to ensure a safe working environment when dealing with steel strips.

- Q: How are steel strips processed for painting?

- Steel strips are processed for painting by undergoing a series of steps including surface cleaning, pretreatment, application of a primer coat, drying, and finally the application of the top coat paint.

- Q: How are steel strips used in the manufacturing of electrical components?

- Steel strips are commonly used in the manufacturing of electrical components due to their various properties and benefits. These strips are typically made from high-quality steel alloys and are cut into desired shapes and sizes to suit specific applications. One of the primary uses of steel strips in the manufacturing of electrical components is for creating magnetic cores. Magnetic cores are essential in transformers, inductors, and other electrical devices that require efficient energy transfer. The steel strips are carefully stacked and laminated to reduce eddy currents and improve magnetic performance. This laminated structure helps minimize energy losses and enhances the overall efficiency of the electrical component. Moreover, steel strips are often used as a base or support material for electrical contacts and connectors. These components require a solid and stable foundation to ensure proper electrical conductivity and secure connections. Steel strips provide excellent mechanical strength and stability, making them ideal for such applications. Additionally, steel strips can be used for shielding purposes in electrical components. Electromagnetic interference (EMI) can adversely affect the performance of sensitive electronic devices. By incorporating steel strips in the design, manufacturers can create an effective barrier against EMI, protecting the electrical component from external interference and ensuring its proper functioning. Furthermore, steel strips are also utilized in the manufacturing of electrical springs and contacts. These components require specific mechanical properties, such as high tensile strength, resilience, and durability. Steel strips possess these attributes and can be easily formed into the desired shape, making them ideal for applications that require repetitive motion or reliable electrical connections. In summary, steel strips play a crucial role in the manufacturing of electrical components. They are used for creating magnetic cores, providing a stable base for contacts and connectors, shielding against electromagnetic interference, and forming springs and contacts with desired mechanical properties. With their versatility and reliability, steel strips contribute to the overall performance and efficiency of electrical devices.

- Q: What are the packaging options for steel strips during transportation?

- The packaging options for steel strips during transportation typically include wooden crates, steel drums, or coil packaging. These options provide protection against damage, ensure stability, and facilitate efficient handling and storage during transit.

Send your message to us

Galvanized Steel Strip with High Quality-SGCC 680*1.0mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords