304 Stainless Steel Sheet/Stainless Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

304/410/409/430/202/201 STAINLESS STEEL PLATE

---Stainless steel plate applies to construction field, ships building industry, petroleum,

chemical industries, war and electricity industries, food processing and medical industry,

boiler heat exchanger,machinery and hardware fields.

Product Features

. Traditional aesthetics outlook

. Suitable for new house or renovation.

. Less joints, watertight

. Long life service

. Tedun also provide relative ridge cap, fasteners and other accessories

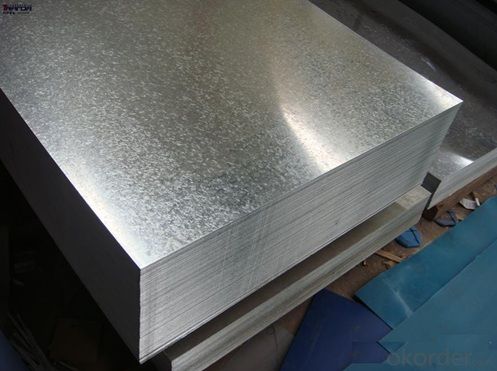

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: 304/410/409/430/202/201

Thickness: 0.15mm~3.0mm,

Width: 1250,600-1250mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

1. How long will we receive the goods ?

45days after receiving workable L/C

1. how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: What are the advantages of using steel strips?

- There are several advantages of using steel strips, including their high strength and durability, excellent corrosion resistance, versatility in various applications, and ease of fabrication and installation. Steel strips are also known for their dimensional accuracy, which ensures precise fitting and uniformity in structures. Additionally, steel strips offer high recyclability, making them an environmentally friendly choice.

- Q: What is the fire resistance of a steel strip?

- The fire resistance of a steel strip can vary depending on various factors such as the thickness and composition of the strip. However, in general, steel has a high fire resistance due to its non-combustible nature and ability to retain its structural integrity even at high temperatures.

- Q: How are steel strips used in the production of elevator components?

- Due to their strength, durability, and versatility, steel strips find widespread application in the manufacturing of elevator components. Elevator guide rails, for instance, heavily rely on these strips as they provide essential support and guidance for the elevator car and counterweight, guaranteeing a smooth and secure movement. To construct the base structure of the guide rails, steel strips are meticulously designed and manufactured from high-quality steel capable of enduring the immense loads and continuous usage experienced by elevator systems. Moreover, steel strips are employed in the production of various other elevator components, including brackets, which are responsible for securely holding different parts of the elevator system together, ensuring stability and reliability. The strips offer the necessary strength and rigidity to bear the weight of the elevator car, counterweight, and other moving elements. Additionally, steel strips are custom-made and shaped to fit the specific dimensions and design requirements of elevator doors. These strips serve as the frame or reinforcement for the door panels, imparting strength and stability while permitting seamless opening and closing. In conclusion, the utilization of steel strips is of paramount importance in the manufacturing of elevator components. Their exceptional strength, durability, and stability enable elevator systems to withstand the rigors of heavy loads, constant usage, and various forces encountered in vertical transportation.

- Q: What are the specifications for steel strips used in the aerospace industry?

- To guarantee the utmost safety and performance, the aerospace industry imposes stringent and meticulous specifications on steel strips. Here are some of the vital requirements: 1. Composition of Materials: Chemical compositions of the steel strips must adhere to specific standards to meet the desired strength, durability, and resistance to corrosion. Stainless steel, high-strength low-alloy (HSLA) steel, and nickel-based alloys are commonly utilized. 2. Tolerances for Dimensions: The steel strips must conform to precise dimensional tolerances to ensure suitable fit and functionality within aerospace components. This encompasses measurements of thickness, width, and length, often indicated in micrometers or inches. 3. Surface Finish: The surface finish of the steel strips plays a crucial role in minimizing friction, preventing corrosion, and optimizing performance. It is often expressed in terms of roughness average (RA) or surface finish grade. Additionally, additional coatings or treatments may be necessary to enhance surface properties. 4. Mechanical Properties: The steel strips employed in aerospace applications must possess specific mechanical properties, including tensile strength, yield strength, elongation, and hardness. These properties guarantee that the strips can withstand the challenging conditions encountered during flight, such as high temperatures, vibrations, and external forces. 5. Heat Treatment: Depending on the intended use, the steel strips may require specific heat treatment processes to enhance their mechanical properties. This may involve techniques such as annealing, quenching, tempering, or precipitation hardening, with the aim of achieving the desired strength, toughness, or ductility. 6. Certification and Testing: Steel strips used in the aerospace industry undergo rigorous testing and certification procedures to ensure compliance with industry standards and regulations. Non-destructive testing methods, such as ultrasonic testing, magnetic particle testing, or dye penetrant inspection, are employed to identify any defects or flaws. It is important to note that the precise specifications for steel strips utilized in the aerospace sector may vary depending on specific applications, aircraft types, and regulatory requirements. Therefore, it is crucial to consult the relevant aerospace standards and specifications for precise details.

- Q: Are steel strips suitable for construction purposes?

- Certainly! Steel strips are suitable for construction purposes. They possess multiple characteristics that make them an excellent option for construction projects. Firstly, their high strength and durability are well-known. With their impressive tensile strength, they can endure heavy loads and resist deformation effectively. This quality makes them suitable for a range of construction applications, including structural framing, roofing, and reinforcement. Furthermore, steel strips exhibit exceptional resistance to corrosion, which is a vital factor in construction projects, particularly in areas with high humidity or exposure to harsh environments. Unlike materials such as wood or concrete, steel strips do not rot, warp, or decay with time, ensuring the longevity and stability of the structure. Moreover, steel strips are highly flexible and can be easily shaped and formed into various sizes and dimensions, making them versatile for different construction requirements. They can be cut, welded, and bent to fit specific needs, allowing for customization and adaptability in construction projects. In addition to their physical properties, steel strips are also cost-effective in the long run. Although the initial investment may be higher compared to other materials, the durability and low maintenance requirements of steel strips result in lower repair and replacement costs over time. This aspect makes them a cost-efficient choice for construction purposes. Overall, steel strips prove to be a suitable material for construction due to their strength, durability, resistance to corrosion, flexibility, and cost-effectiveness. They offer numerous advantages that contribute to the quality, stability, and longevity of construction projects.

- Q: How are steel strips embossed or patterned?

- Steel strips can be embossed or patterned through various techniques. One common method is through the use of embossing rolls or dies. These rolls or dies are engraved with specific patterns or designs, which are then pressed onto the steel strip under high pressure. This process creates raised or recessed areas on the surface of the strip, resulting in the desired pattern or design. Another technique used is called laser engraving. In this method, a laser beam is directed onto the steel strip, selectively removing material to create the desired pattern. This process allows for intricate and precise designs to be achieved. Additionally, steel strips can also be patterned using chemical etching. A resist material is applied to the surface of the strip, protecting certain areas from the etching solution. The strip is then immersed in the etching solution, which selectively removes material from the unprotected areas, resulting in the desired pattern. Overall, steel strips can be embossed or patterned using a variety of techniques such as embossing rolls or dies, laser engraving, and chemical etching. These methods offer flexibility in design options and can create visually appealing and functional patterns on steel strips.

- Q: What are the safety precautions to be taken while handling steel strips?

- To ensure the safety of yourself and others, it is crucial to adhere to specific safety measures when dealing with steel strips. Consider the following precautions: 1. Personal Protective Equipment (PPE): Make sure to wear appropriate PPE, including safety goggles, gloves, and steel-toed boots. These will safeguard your eyes, hands, and feet from potential injuries caused by sharp edges or flying debris. 2. Proper Lifting Technique: When lifting steel strips, always bend your knees and utilize your leg muscles instead of your back. Keep the load close to your body and avoid twisting or jerking movements to prevent strains or sprains. 3. Use Lifting Equipment: If the steel strips are heavy or bulky, employ mechanical lifting aids such as hoists or forklifts to minimize the risk of injuries. Ensure that the equipment is in good working condition and follow the correct operating procedures. 4. Secure and Stabilize the Load: When transporting steel strips, ensure that the load is securely fastened and well-balanced on the vehicle or pallet. Use straps or chains to prevent shifting or falling during transportation. 5. Be Mindful of Sharp Edges: Exercise caution when handling steel strips as they often have sharp edges that can cause cuts or punctures. Avoid dragging or sliding them against surfaces or other objects. 6. Safe Storage: When storing steel strips, organize them in a manner that prevents them from falling or toppling over. Utilize appropriate racks or shelves designed for heavy loads. 7. Maintain a Clean Work Area: Keep the work area free from clutter, debris, or any potential hazards that may result in slips, trips, or falls. Regularly sweep the floor to remove metal shavings or other sharp objects. 8. Be Aware of Hot or Cold Surfaces: Steel strips can conduct heat or cold, so handle them cautiously to avoid burns or frostbite. Use insulated gloves or other protective measures when dealing with extreme temperatures. 9. Follow Safe Cutting Procedures: When cutting steel strips, employ suitable tools and adhere to proper cutting techniques. Avoid using damaged or dull tools as they can lead to accidents. 10. Training and Supervision: Ensure that all individuals handling steel strips receive proper training in safe handling techniques and are aware of potential risks. Regularly review safety procedures and provide supervision to ensure compliance. By adhering to these safety precautions, you can minimize the likelihood of accidents or injuries while working with steel strips. Always prioritize safety and take the necessary measures to protect yourself and others in the workplace.

- Q: What are the dimensions of a typical steel strip?

- The dimensions of a typical steel strip can vary depending on its intended application and industry standards. However, common dimensions for steel strips range from 0.5 inches to 12 inches in width and 0.005 inches to 0.25 inches in thickness. The length of a steel strip is typically determined by the coil it is supplied in, which can vary from several hundred to several thousand feet long. It is important to note that these dimensions are general guidelines and may vary based on specific requirements and manufacturing processes for different applications.

- Q: How do steel strips contribute to product longevity in various applications?

- Steel strips contribute to product longevity in various applications in several ways. Firstly, steel strips are highly durable and resistant to wear and tear. They can withstand heavy loads, impact, and harsh environmental conditions without getting deformed or damaged easily. This strength and durability ensure that products made with steel strips have a longer lifespan compared to those made with other materials. Secondly, steel strips have excellent corrosion resistance. They are often coated with protective layers, such as zinc or chromium, to prevent rusting and corrosion. This protective coating acts as a barrier, preventing moisture, chemicals, and other corrosive elements from reaching the underlying steel. As a result, products made with steel strips are less likely to corrode and degrade over time, ensuring their longevity. Moreover, steel strips offer high strength-to-weight ratio, meaning they provide great strength while being relatively lightweight. This characteristic is particularly beneficial for applications where weight is a concern, such as in automotive or aerospace industries. The use of steel strips allows for the creation of lighter products without sacrificing their structural integrity and durability. Furthermore, steel strips can be easily formed and fabricated into various shapes and sizes, making them highly versatile. This versatility enables manufacturers to create products tailored to specific applications, ensuring optimal performance and longevity. Additionally, steel strips can be efficiently joined or welded together, allowing for the construction of complex structures that are strong and long-lasting. Lastly, steel strips are recyclable. At the end of their lifespan, steel strips can be recycled and used to create new products. This recyclability not only reduces the environmental impact of steel production but also contributes to the sustainability of products made with steel strips. In conclusion, steel strips contribute to product longevity in various applications by providing durability, corrosion resistance, high strength-to-weight ratio, versatility in shaping and fabrication, and recyclability. These characteristics ensure that products made with steel strips can withstand the test of time and continue to perform reliably for extended periods.

- Q: What are the environmental considerations associated with steel strip production?

- Some environmental considerations associated with steel strip production include the emission of greenhouse gases during the production process, the consumption of large amounts of energy and natural resources, the generation of toxic waste materials, and the potential for habitat destruction and water pollution. Additionally, the transportation of raw materials and finished products can contribute to air pollution and carbon emissions.

Send your message to us

304 Stainless Steel Sheet/Stainless Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords