Galvanized Steel Sheet Gi Coil for Building Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:ST010

Standard:ASTM, JIS, GB, AISI, DIN

Steel Grade:Q195

Certification:ISO, SGS, BV, RoHS, IBR

Surface Treatment:Galvanized

Technique:Cold Rolled

Application:Packing,Gutter Ect.

Edge:Mill

Stock:Stock

THK:0.13-3mm

Width:10mm-550mm

Inner Diameter:200mm to 600mm

Export Markets:Global

Additional Info.

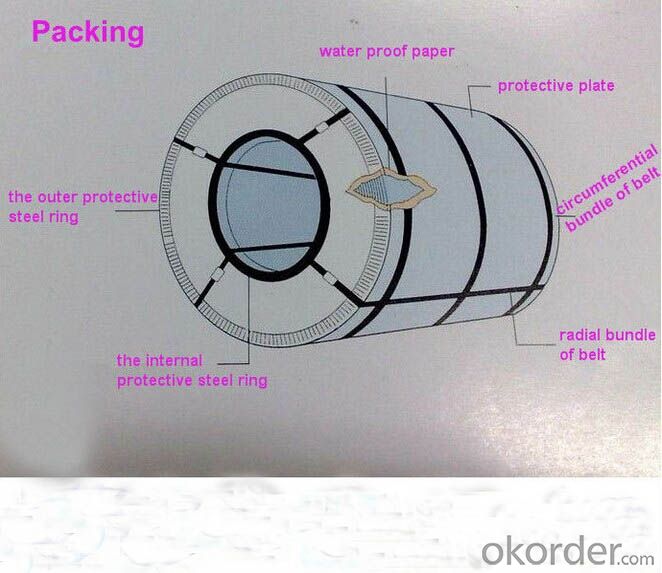

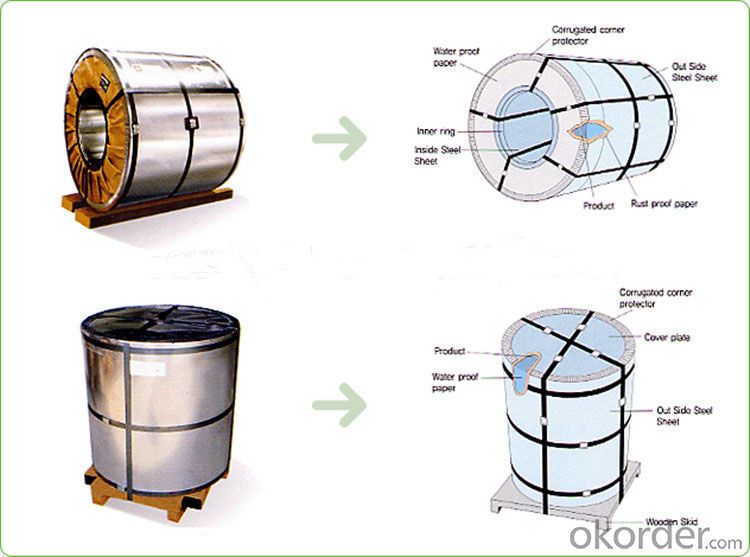

Packing:Wood Pallets

Standard:OEM

Origin:China

Production Capacity:30000 Tons Each Month

Product Description

1. Thickness: 0.18-1.5mm;

2. Width: 50-914mm;

3. Hardness: 380MPa-450MPa;

4. Specification: 0.35*50, 0.4*45, 0.4*65, 0.4*68, etc.;

5. Surface waxed and edges deburred;

6. Standard: As per buyers' specifications among Q195-Q345B in the GB standard;

7. Package: Inner is protect humidity-proof waw paper, medium is plastic film, outer is sackcloth or compound paper packing, or as per customer's requirements.

| Standard | AISI, ASTM, BS, DIN, GB, JIS, etc |

| Grade | SGCC, DX51D, DX53D, DX54D, etc |

| Thickness | 0.14-2.5mm |

| Width | less than 600mm |

| Inner Diameter | 508/610mm |

| Coil Weight | 1.5-4.0T |

| Zinc Coating | 60g/m 2 -180g/m 2 |

| Spangle State | regular spangle, small spangle, big spangle, non-spangle |

| Surface Treatment | Chromate, Oil, Lacquer Seal, Phosphating, etc |

Product show:

Package:

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: What is the width range of steel coils?

- The width range of steel coils can vary depending on the specific requirements and industry standards, but generally, it can range from a few millimeters to several meters.

- Q: I got my dog those nice looking stainless steel water and food bowls (looks great next to my kitchen appliances...haha). The thing is my dog will drink from the toilet or a plastic bowl but not out of his bowl...I was wondering if those stainless steel bowls change the taste of food and water?

- Personally I use stainless steel for my own dogs because ti is easy to keep clean, and doesn't weigh too much when I am carrying 3 large bowls full of food. Plus when I drop them they don't break. The only reason I don't use plastic is because my dogs like to chew anything plastic :P I use plastic for my foster cats and foster puppies and have never had any sort of infection. Personally I think that is some sort of myth as I have never known anyone's pet to get an infection from a plastic bowl. As long as you keep them clean, plastic or stainless are both fine

- Q: What are the typical coil thickness options?

- The typical coil thickness options vary depending on the specific application and industry. However, common coil thickness options range from 0.005 inches (0.13 mm) to 0.250 inches (6.35 mm).

- Q: How are steel coils used in the manufacturing of agricultural trailers?

- Steel coils are used in the manufacturing of agricultural trailers to provide strength, durability, and stability to the trailer's frame, ensuring it can withstand heavy loads and harsh working conditions. These coils are typically shaped and welded to create the trailer's structural components, such as the chassis, sidewalls, and flooring. Additionally, steel coils can be cut and formed into various parts, including axles, suspension systems, and hitch assemblies, to further enhance the trailer's performance and functionality in agricultural operations.

- Q: What is the weight of a typical steel coil?

- The weight of a typical steel coil can vary depending on its size and thickness, but it typically ranges from a few thousand pounds to several tens of thousands of pounds.

- Q: What is the maximum stacking height for steel coils?

- The maximum stacking height for steel coils depends on various factors such as the weight and size of the coils, the strength of the supporting structure, and the safety regulations and guidelines in place. It is recommended to consult the manufacturer's specifications and industry standards to determine the appropriate maximum stacking height for steel coils in a specific situation.

- Q: How do steel coils contribute to the manufacturing of electrical equipment?

- Steel coils play a crucial role in the manufacturing of electrical equipment due to their unique properties and versatility. Firstly, steel coils are used in the production of transformer cores, which are essential components in electrical equipment. The magnetic properties of steel make it an ideal material for transformer cores as it allows for efficient energy transfer and reduces energy losses. The coil shape of the steel enables it to generate a magnetic field that facilitates the transformation of voltage levels, thus ensuring the proper functioning of electrical equipment. Moreover, steel coils are commonly used in the production of motors and generators. These devices rely on magnetic fields to convert electrical energy into mechanical energy and vice versa. The coil shape of the steel allows for the creation of electromagnetic fields, which are necessary for the operation of motors and generators. Additionally, the strength and durability of steel ensure that the coils can withstand the high temperatures and mechanical stresses that are often encountered in electrical equipment. Furthermore, steel coils are utilized in the construction of electrical conductors, such as wires and cables. These conductors enable the transmission of electricity from power sources to various electrical devices. Steel, with its high electrical conductivity, ensures efficient power transmission while also providing mechanical strength and protection from external factors such as corrosion and wear. The coil shape of steel wires further enhances their flexibility, making them suitable for various applications in electrical equipment manufacturing. Overall, steel coils contribute significantly to the manufacturing of electrical equipment by providing the necessary magnetic properties for transformer cores, enabling the generation of electromagnetic fields in motors and generators, and facilitating efficient power transmission in electrical conductors. Their versatility, strength, and durability make steel coils an indispensable component in the production of reliable and high-performance electrical equipment.

- Q: What are the potential dangers of handling steel coils?

- There are several potential dangers associated with handling steel coils. Firstly, steel coils are heavy and can pose a risk of physical injury if not handled properly. The weight of the coils can cause strains, sprains, or even more serious injuries if dropped or mishandled. This is particularly true when using manual lifting equipment or when attempting to move the coils without proper training or assistance. Secondly, steel coils often have sharp edges or protruding parts that can cause cuts or puncture wounds if not handled with care. These sharp edges can be especially hazardous when attempting to manipulate or position the coils during transportation or storage. It is important to wear appropriate personal protective equipment, such as gloves, to minimize the risk of injury. In addition, steel coils can become unstable if not adequately secured or balanced. Improper stacking or storage of the coils can lead to them shifting or falling, potentially causing serious injuries or damage. It is crucial to follow proper stacking and storage procedures, including using appropriate equipment and supports, to ensure stability and prevent accidents. Furthermore, steel coils are often stored in areas with limited space or uneven surfaces, increasing the risk of trips, falls, or collisions. It is essential to maintain clear and well-organized storage areas, free of obstacles or hazards, to reduce the likelihood of accidents. Lastly, steel coils can be subject to corrosion or rust, which can weaken the metal and compromise their structural integrity. This can increase the risk of the coils collapsing or breaking during handling, potentially causing injuries or damage to property. Regular inspections and maintenance of the coils, as well as proper storage in dry and well-ventilated areas, can help mitigate this risk. Overall, the potential dangers of handling steel coils include physical injuries from their weight and sharp edges, instability during transportation or storage, accidents due to limited space or uneven surfaces, and the risk of structural failure due to corrosion or rust. It is crucial to follow proper safety protocols, receive appropriate training, and use the necessary equipment to minimize these risks and ensure safe handling of steel coils.

- Q: How are steel coils used in the manufacturing of automotive suspension systems?

- Steel coils are used in the manufacturing of automotive suspension systems as they provide the necessary support and resistance to absorb shocks and vibrations. These coils, also known as coil springs, are typically positioned between the vehicle's frame and the suspension system to enhance stability and ensure a smooth ride.

- Q: What are the common uses of cold rolled steel coils?

- Cold rolled steel coils are commonly used in a variety of industries and applications. They are frequently utilized in the automotive industry for manufacturing parts such as automobile bodies, frames, and components. Cold rolled steel coils are also widely employed in construction for producing structural components, roofing, and siding. Additionally, they are used in the manufacturing of appliances, furniture, and various electrical products. The smooth and consistent surface of cold rolled steel coils makes them ideal for applications that require a high-quality finish, such as in the production of kitchen utensils and decorative items.

Send your message to us

Galvanized Steel Sheet Gi Coil for Building Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords