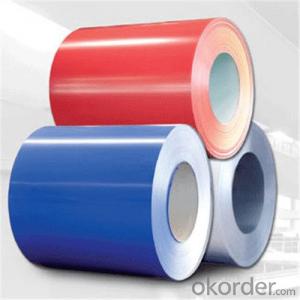

Galvanized steel coils hot dipped galvanized

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

galvanized steel coil

1.Thickness:0.135-4.0mm

2.Width:600-1500mm

3.Zinc:40g-275g

4.Material:SGCC,DX51D,G550,SPGC,etc.

product name | Galvanized steel coils |

thickness | 0.135mm-4.0mm |

width | 600mm-1500mm762mm,914mm,1000mm,1200mm,1219mm,1250mm |

zinc coating | 40g,60g, 80g, 90,100g, 120g, 140g,180g, 200g, 250g, 275g and so on. |

standard | ASTM, AISI, DIN, GB |

material | SGCC,DC51D,DX51D,DX52D,,SGCD,Q195,Q235,SGHC,DX54D, S350 GD, S450 GD,S550 GD |

spangle | zero spangle, regular spangle or normal spangle |

surface treatment | chromated and oiled, chromated and non-oiled |

packing | export standard. |

payment | T/T, L/C or DP |

min order | 25 tons (one 20ft FCL) |

coil weight | 3-8ton or as client requirement. |

quality | soft or hard quality |

Galvanized steel coils

STEEL GRADE | CHEMICAL COMPOSITION % | MECHANIC PROPERTY | C.B OF COATING | COATING | ||||||||||

C | Si | Mn | S | P | T.S | Y.S | E.L | |||||||

x103 | x103 | x102 | x103 | x103 | Mpa | Mpa | % | d=0 180° | G/M² | |||||

JIS G3302 SGCC | 12 | 30 | 41 | 31 | 21 | 480 | 300 | 13 | OK | Z60-150 | ||||

JIS G3302 SGCH | 12 | 10 | 21 | 18 | 8 | 680 | 650 | OK | Z60-150 | |||||

ASTM A653 CS.B | 20 | 30 | 60 | 35 | 30 | 386 | 205~380 | 20 | OK | Z80-275 | ||||

DX51D+Z | 29 | 21 | 18 | 1.8 | 11 | 355 | 245 | 38 | OK | Z80-275 | ||||

G550 | 20 | 6 | 73 | 5 | 17 | 715 | 654 | 8 | OK | Z80-275 | ||||

- Q: which one(glass or steel)has more power and velocity? im planning on using my slingshot for hunting.

- definitely steel. i used to hit bullseyes with a good slingshot, and you need heavy, perfectly spherical small steel shot. smaller than a marble, bigger than a bb.

- Q: How are steel coils used in the production of HVAC ductwork?

- Steel coils are commonly used in the production of HVAC ductwork due to their durability and strength. The coils are typically made of galvanized steel, which provides protection against corrosion and extends the lifespan of the ductwork. The manufacturing process begins with the steel coils being unrolled and cut into the desired length. The coils are then fed through a machine that shapes the steel into a rectangular or round duct form. This shaping process can be done using various techniques such as roll forming or press braking. Once the steel has been formed into the desired duct shape, it is then joined together using various methods such as welding or locking mechanisms. Welding is often used for rectangular ducts, while locking mechanisms like snap locks or Pittsburgh seams are commonly used for round ducts. These joining techniques ensure that the ductwork is secure and airtight. After the ductwork has been assembled, it may undergo additional processes such as insulation or lining. Insulation helps to reduce heat loss or gain, while lining can improve the acoustic properties of the ductwork. These additional steps are often done to meet specific requirements or regulations. Overall, steel coils play a crucial role in the production of HVAC ductwork as they provide strength, durability, and protection against corrosion. The versatility of steel allows for various shapes and sizes of ductwork to be fabricated, making it a popular choice for HVAC systems.

- Q: How are steel coils used in the manufacturing of steering systems?

- Steel coils are used in the manufacturing of steering systems as they are shaped and formed into various components such as shafts, gears, and brackets. These components are crucial for ensuring the stability, strength, and functionality of the steering system.

- Q: What are the common challenges faced in steel coil production?

- Some common challenges faced in steel coil production include ensuring consistent quality and thickness of the coil, maintaining efficient production rates, managing inventory and storage of coils, addressing issues related to coil surface defects and handling, and adhering to strict safety regulations. Additionally, fluctuations in raw material prices and market demand pose further challenges for steel coil producers.

- Q: Can steel coils be coated with scratch-resistant materials?

- Yes, steel coils can be coated with scratch-resistant materials. These materials can provide a protective layer that minimizes the risk of scratches and damage to the steel coils during transportation, handling, and storage.

- Q: How are steel coils processed for edge trimming or conditioning?

- Steel coils are processed for edge trimming or conditioning through a series of steps. First, the steel coils are unwound and fed into a machine that trims the edges to remove any irregularities or imperfections. This process helps ensure that the edges of the steel coils are straight and smooth. After edge trimming, the coils may undergo further conditioning processes such as leveling, slitting, or recoiling, depending on the specific requirements of the end product. These processes help to refine the steel coils and prepare them for various applications in industries such as automotive, construction, or manufacturing.

- Q: How are steel coils used in the manufacturing of signage?

- Steel coils are used in the manufacturing of signage as they serve as the base material for creating durable and sturdy sign structures. These coils are shaped, cut, and processed into various sign components, such as frames, brackets, and supports, which provide stability and strength to the signage. Additionally, steel coils can be coated or painted to enhance the appearance and protect the signage from corrosion, making them ideal for outdoor applications.

- Q: What could the impurities in steel wool be?And why are they there?Thanks for your help :)

- Impurities in steel wool would be of the elemental type. I'm sure steel wool is a mixture of different low grade not good for much of anything else materials. There may be excessive impurities such as lead, cobalt, boron, aluminum etc... in the steel wool. There may also be solvent residue on the wool i.e cleaner, lubricant etc.. I'm sure every batch is different - I know the iron level is high thats what makes them rust quickly.

- Q: What are the common applications of galvalume steel coils?

- Galvalume steel coils are commonly used in various applications including roofing, siding, and automotive manufacturing. They are highly valued for their superior corrosion resistance, high strength-to-weight ratio, and aesthetic appeal. Additionally, these coils find extensive use in construction, agriculture, and industrial sectors due to their durability and cost-effectiveness.

- Q: What are the common methods of welding steel coils?

- Some common methods of welding steel coils include gas metal arc welding (GMAW), also known as MIG welding, and submerged arc welding (SAW). These methods offer efficient and reliable ways to join steel coils together, ensuring strong and durable welds.

Send your message to us

Galvanized steel coils hot dipped galvanized

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords