Galvanized Hot Rolled Channel Steel (UL, SGS, IEC and CE)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Hot Rolled Channel Steel (UL, SGS, IEC and CE) Details

Standard: | AISI,ASTM,BS, DIN,GB,JIS | Dimensions: | 41*21*2.0 | Grade: | steel |

Place of Origin: | China (Mainland) | Brand Name: | CNBM | Model Number: | BSC-BS |

Shape: | C Channel | Application: | construction material or bracket | Perforated Or Not: | Is Perforated |

color: | Customized | certificates: | UL, NEMA, CE, IEC, SGS and ISO9001-2008 | business model: | manufacturer and exporter |

finish: | HDG/Pre-galvanized/Powder Coating/Electro | ||||

Packaging & Delivery

Packaging Detail: | Standard packaging or customized packaging |

Delivery Detail: | Usually within 20 days |

Galvanized Hot Rolled Channel Steel (UL, SGS, IEC and CE) Specifications

1. Specialized manufacturer and exporter

2. UL, cUL, CE, IEC, TUV and SGS

3. ISO9001-2008

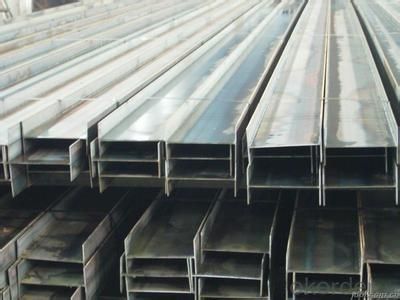

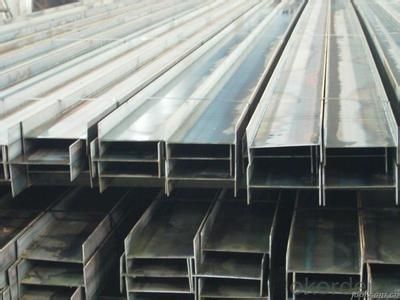

Galvanized Hot Rolled Channel Steel (UL, SGS, IEC and CE) Pictures

- Q: Is the bottom of the channel not real? Why do we open the hole? What's the reason?

- Is the most ideal processing equipment of stainless steel and flat iron, steel, steel, iron pipes and other processing households, profile processing businesses.

- Q: Are steel channels suitable for use in agricultural structures?

- Agricultural structures can indeed make use of steel channels. Steel itself is a robust and enduring material, capable of enduring the often harsh environmental conditions that are typically present in agricultural settings. Not only is it resistant to pests, rot, and decay, but it also offers a long-lasting solution for constructing buildings such as barns, storage sheds, and livestock shelters. Steel channels prove particularly advantageous in agricultural structures, as they not only provide essential structural support but can also be effortlessly incorporated into the building's design. Moreover, steel possesses fire-resistant properties, a critical aspect to consider when handling the flammable materials commonly found on farms. Ultimately, the utilization of steel channels in agricultural structures ensures stability, durability, and safety.

- Q: How do steel channels contribute to the overall safety of a project?

- Steel channels play a crucial role in enhancing the overall safety of a project in several ways. Firstly, these structural components provide robust support and reinforcement to various structures, such as buildings, bridges, and infrastructure projects. The strength and durability of steel channels make them capable of withstanding heavy loads and extreme weather conditions, minimizing the risk of structural failure or collapse. Moreover, steel channels are fire-resistant, which is a significant advantage in terms of safety. In the event of a fire, steel channels can withstand high temperatures for an extended period, offering valuable time for evacuation and minimizing the spread of flames. This fire resistance property makes steel channels highly suitable for projects where fire safety is a critical concern, such as high-rise buildings, industrial facilities, and transportation infrastructure. Another important contribution of steel channels to project safety is their ability to resist corrosion. Steel channels are typically made from galvanized or stainless steel, which are highly resistant to rust and corrosion. This resistance ensures the structural integrity of the channels over time, reducing the risk of deterioration and potential hazards. Consequently, projects utilizing steel channels can enjoy a longer lifespan and require less maintenance, ultimately enhancing safety and reducing the need for costly repairs. Additionally, steel channels offer versatility in design and construction. They can be easily customized and fabricated to suit specific project requirements, allowing for precise and secure connections between various structural elements. This versatility ensures accurate alignment and integration of components, minimizing the chances of structural instability or compromise. Lastly, steel channels provide excellent load-bearing capacity, enabling the distribution of weight and stress evenly across a structure. This even distribution of loads prevents localized points of weakness or excessive strain, thereby enhancing the overall stability and safety of the project. In conclusion, steel channels contribute significantly to the overall safety of a project by providing robust support, fire resistance, corrosion resistance, versatility in design, and excellent load-bearing capacity. By incorporating steel channels into construction projects, the risk of structural failure, fire hazards, and deterioration can be greatly minimized, ensuring the safety and longevity of the project.

- Q: Can steel channels be used for supporting rooftop gardens?

- Yes, steel channels can be used for supporting rooftop gardens. Steel channels are strong and durable, making them suitable for supporting the weight and load of rooftop gardens. They provide structural support and stability, ensuring that the garden remains secure and stable on top of a building. Steel channels can be used to create raised beds or platforms for the garden, allowing for proper drainage and a solid foundation. Additionally, steel channels can be customized and fabricated to fit the specific requirements and dimensions of the rooftop garden, making them a versatile choice for this purpose.

- Q: Channel steel is a strip of steel with a cross section.

- Channel steel is a strip of steel with a cross section. The specifications of the method, such as 120*53*5, mean waist height of 120 mm, leg width of 53 mm channel, waist thickness of 5 mm channel, or called 12# channel. The same height of the channel, if there are several different leg width and waist thickness, also need to add a, B, C on the right side of the model to distinguish, such as 25a#, 25b#, 25c# and so on.

- Q: Can steel channels be used in architectural facades?

- Yes, steel channels can be used in architectural facades. Steel channels offer structural stability, durability, and versatility, making them suitable for various architectural applications, including facades. They can be used to create visually appealing designs, provide support for cladding materials, and serve as a framework for architectural features such as windows or louvers.

- Q: What are the sustainability benefits of using steel channels?

- The utilization of steel channels brings forth a multitude of sustainability advantages. To begin with, steel is renowned as one of the most extensively recycled materials worldwide. This implies that by employing steel channels, the demand for fresh raw materials is diminished, as well as the energy consumption and greenhouse gas emissions associated with their extraction and production. By choosing steel channels, we have the ability to contribute to a circular economy and minimize waste generation. Furthermore, steel is widely recognized for its durability and long-lasting nature. Steel channels exhibit exceptional resistance to corrosion and can endure harsh environmental conditions, making them a sustainable choice for various applications. The durability of steel channels reduces the necessity for frequent replacements, thereby conserving resources and mitigating waste generation. Additionally, steel is an energy-efficient material. The production process of steel channels necessitates less energy in comparison to other construction materials such as concrete or aluminum. This energy efficiency results in lower carbon emissions during manufacturing, thereby contributing to an overall reduction in the carbon footprint. Moreover, steel channels can be easily repurposed and reused in diverse applications. This versatility enables the material to adapt to different uses, consequently minimizing the requirement for new production and reducing the environmental impact. Steel channels can be recycled and transformed into novel steel products, further prolonging their lifespan and decreasing the demand for virgin materials. Lastly, steel channels possess the advantageous characteristic of being lightweight when compared to other construction materials. This attribute reduces transportation costs, energy consumption during shipping, as well as the associated emissions. The selection of steel channels can make a valuable contribution to a more sustainable supply chain by mitigating carbon emissions and minimizing the environmental impact of logistics. In conclusion, the utilization of steel channels offers a multitude of sustainability benefits, including high recyclability, durability, energy efficiency, adaptability, and lightweight nature. By opting for steel channels, we have the capacity to contribute to a construction industry that is more sustainable and environmentally friendly.

- Q: Are steel channels suitable for architectural applications?

- Yes, steel channels are indeed suitable for architectural applications. Steel channels are versatile and durable, making them an excellent choice for various architectural projects. They can be used for structural purposes, such as supporting large loads or creating frameworks for buildings. Steel channels also offer the advantage of being highly resistant to corrosion and weathering, making them suitable for both indoor and outdoor architectural applications. They can withstand extreme environmental conditions, ensuring the longevity of the structures they are used in. Moreover, steel channels provide design flexibility, as they can be easily fabricated and shaped to meet specific architectural requirements. They can be cut, welded, and formed into various shapes, allowing architects to create unique and aesthetically pleasing structures. Steel channels are commonly used in architectural applications such as curtain wall systems, façades, roof supports, and staircases. They provide strength and stability while also adding a modern and industrial aesthetic to the design. In summary, steel channels are highly suitable for architectural applications due to their strength, durability, resistance to corrosion, and design flexibility. They offer architects and designers the opportunity to create innovative and long-lasting structures.

- Q: Are steel channels suitable for electrical installations?

- Indeed, electrical installations can indeed benefit from the use of steel channels. Due to their robustness and durability, steel channels are frequently employed for cable management and support in electrical setups. By utilizing steel channels, one can establish a dependable and secure means of routing and safeguarding electrical cables, thereby minimizing the likelihood of harm and ensuring an orderly and systematic installation. Moreover, steel channels boast exceptional fire and impact resistance, rendering them a prudent selection for electrical applications. Furthermore, their availability in a multitude of sizes and configurations allows for flexibility when designing and tailoring electrical systems.

- Q: What is the difference between steel tubes such as channel steel and square tube?

- Channel steel is divided into ordinary channel steel and light channel steel. Standard Specification for hot-rolled plain channel steel is 5-40#. Specifications for hot rolled flexible channel steel supplied by supply and demand agreement are 6.5-30#. Channel steel is mainly used for building structures, vehicle manufacturing, other industrial structures and fixed plates, cabinets, etc., and channel steel is often used in conjunction with i-beam.

Send your message to us

Galvanized Hot Rolled Channel Steel (UL, SGS, IEC and CE)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords