Galvanized Deformed Bars in Coils 6mm to 12mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Galvanized Deformed Bars in Coils 6mm to 12mm

Description of Galvanized Deformed Bars in Coils

1, Diameter: 5.5mm-10mm Galvanized Deformed Bars in Coils

10m- 40mm Galvanized Deformed Bars in Coils

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Galvanized Deformed Bars in Coils

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

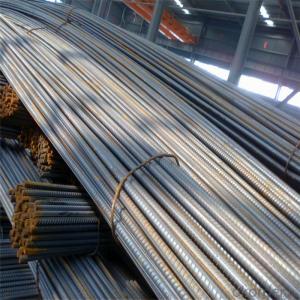

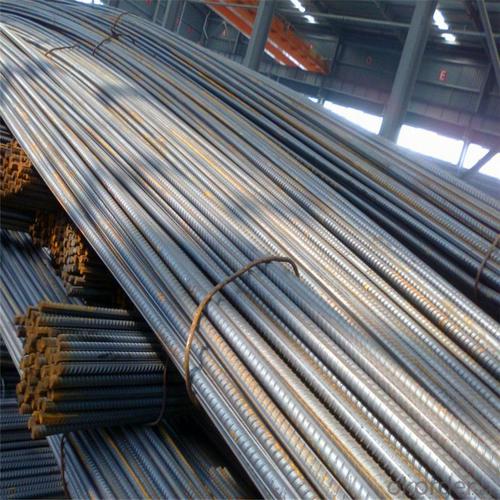

Products Show of Galvanized Deformed Bars in Coils

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How is special steel used in the defense manufacturing process?

- Special steel is commonly used in the defense manufacturing process due to its exceptional strength, durability, and resistance to extreme conditions. It is utilized in the production of various defense equipment and components such as armored vehicles, submarines, aircraft carriers, and ballistic missiles. Special steel is crucial for enhancing the overall performance, reliability, and safety of these defense systems, making it an essential material in the defense manufacturing industry.

- Q: What are the applications of special steel in the agriculture supply chain?

- Special steel has various applications in the agriculture supply chain, including the manufacturing of agricultural machinery and equipment such as tractors, harvesters, and irrigation systems. It is also used in the production of storage containers, silos, and fencing materials for farms. Additionally, special steel is utilized for constructing infrastructure like bridges, railings, and support structures in agricultural facilities. Overall, the use of special steel in the agriculture supply chain ensures durability, strength, and longevity of essential equipment and structures, enhancing efficiency and productivity in the farming industry.

- Q: What are the different surface hardening techniques for special steel?

- To enhance the mechanical properties and improve the wear resistance of special steel, there exists a range of surface hardening techniques that can be employed. These techniques encompass: 1. Case hardening: Through diffusion, carbon or nitrogen is introduced into the steel surface. By subjecting the steel to an environment rich in carbon or nitrogen, the atoms disseminate into the surface layer, resulting in the creation of a hardened case while maintaining a resilient core. 2. Nitriding: The process of introducing nitrogen into the steel surface to enhance its hardness is known as nitriding. By placing the steel in an environment abundant in nitrogen at elevated temperatures, a hardened surface layer is formed, exhibiting improved resistance to wear and corrosion. 3. Carburizing: Carbon is introduced into the steel surface through carburizing. By heating the steel in an environment rich in carbon, the carbon atoms diffuse into the surface layer, leading to the development of a hardened case with heightened hardness and wear resistance. 4. Induction hardening: Utilizing an induction coil, induction hardening is a localized technique for surface hardening. The steel is heated using the induction coil and then swiftly quenched, resulting in a hardened surface layer characterized by high hardness and enhanced wear resistance. 5. Flame hardening: Flame hardening is an alternative localized method for surface hardening. The steel surface is heated using a high-temperature flame and swiftly quenched. This technique generates a hardened surface layer with increased hardness and resistance to wear. 6. Laser hardening: Laser hardening is a precise and localized surface hardening technique. By employing a laser beam to heat the desired area of the steel, followed by rapid quenching, a hardened surface layer with enhanced mechanical properties is formed. By employing these surface hardening techniques, special steel can experience significant improvements in durability, strength, and resistance to wear and corrosion, making it highly suitable for diverse industrial applications. The selection of the most suitable technique is contingent upon factors such as the desired level of hardness, the complexity of the steel component, and the specific requirements of the application.

- Q: What are the heat treatment processes used for special steel?

- Some of the heat treatment processes used for special steel include annealing, quenching, tempering, and hardening. Annealing involves heating the steel to a specific temperature and slowly cooling it to improve its ductility and reduce internal stress. Quenching is a rapid cooling process that hardens the steel by quickly cooling it from a high temperature, creating a tough and wear-resistant material. Tempering is a process that follows quenching, where the steel is reheated to a lower temperature to reduce brittleness and improve toughness. Hardening involves heating the steel to a high temperature and then rapidly cooling it to increase its hardness and strength. These heat treatment processes are used to enhance the properties and performance of special steel for various applications.

- Q: How is alloy steel used in the production of gears and shafts?

- Alloy steel is commonly used in the production of gears and shafts due to its excellent combination of strength, durability, and resistance to wear and corrosion. The alloying elements such as manganese, chromium, nickel, and molybdenum enhance the properties of the steel, making it suitable for high-stress applications. The use of alloy steel in gears and shafts ensures their ability to withstand heavy loads, transmit power efficiently, and maintain dimensional stability under extreme operating conditions, thus increasing the overall lifespan and performance of the components.

- Q: How is leaded steel used in machining operations?

- Leaded steel is commonly used in machining operations as it improves the machinability of the steel by reducing friction and cutting forces. The addition of lead in the steel composition allows for smoother and more efficient cutting, resulting in better surface finish and dimensional accuracy of machined parts.

- Q: How is maraging steel used in the production of rocket and missile components?

- Maraging steel is used in the production of rocket and missile components due to its exceptional strength, toughness, and resistance to heat and corrosion. Its unique properties make it ideal for critical parts like rocket casings, engine components, and missile guidance systems, where high performance and reliability are paramount. The steel's ability to handle extreme conditions, such as high pressures and temperatures, ensures that these components can withstand the rigorous demands of aerospace applications.

- Q: What is the cost of special steel compared to regular steel?

- The cost of special steel is typically higher than that of regular steel due to its unique properties and manufacturing processes.

- Q: How does sulfur affect the machinability of special steel?

- Sulfur can have both positive and negative effects on the machinability of special steel. On one hand, sulfur acts as a free-machining element when added in small amounts. It forms sulfide inclusions that help improve the chip-breaking ability during machining, resulting in better surface finish, reduced tool wear, and improved cutting speeds. This is particularly beneficial for high-speed machining operations. On the other hand, excessive sulfur content can have detrimental effects on machinability. High levels of sulfur can lead to the formation of brittle sulfide inclusions, causing poor machinability and reduced mechanical properties. It can result in increased tool wear, poor surface finish, and lower cutting speeds. Additionally, sulfur can promote the formation of built-up edge, which further hampers the machinability of special steel. Therefore, it is crucial to maintain an optimal sulfur content in special steel to strike a balance between improved machinability and maintaining the desired mechanical properties. Proper control of sulfur levels in the steel composition, along with appropriate machining techniques and tool selection, is necessary to achieve efficient and high-quality machining of special steel.

- Q: How does special steel contribute to improving product functionality?

- Special steel contributes to improving product functionality in several ways. Firstly, special steel offers enhanced strength and durability, allowing products to withstand higher loads and perform under extreme conditions. It also provides superior resistance to corrosion, which extends the lifespan of products and reduces maintenance costs. Additionally, special steel can be tailored to specific applications, such as high-temperature environments or magnetic properties, further enhancing product functionality. Overall, the use of special steel results in more reliable and efficient products, ultimately benefiting consumers and industries alike.

Send your message to us

Galvanized Deformed Bars in Coils 6mm to 12mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords