Galvanized Cold Formed Channel Steel 2015 Hot Sell

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

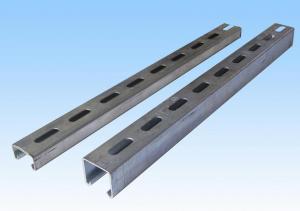

2015 Hot Sell Galvanized Cold Formed Channel Steel Details

| Standard: | AISI,BS,GB | Dimensions: | Produced according to customer requirements |

| Place of Origin: | China (Mainland) | Grade: | Q195 Q235 Q345 |

| Shape: | C Channel | Perforated Or Not: | Not Perforated |

| Model Number: | 41*41*2.0;100*50*20*3.0 |

Packaging & Delivery

| Packaging Detail: | standard packaging or cusomized packaging |

| Delivery Detail: | Usually within 20 days |

2015 Hot Sell Galvanized Cold Formed Channel Steel Specifiction:

Commodity | Galvanized Cold Formed Channel Steel |

Length | The length can be decided by clients |

Specification | a=20-300mm b=20-200mm c=5-20mm t=0.5mm-4mm |

Material | Steel |

Surface treatment | slotted hole |

spraying | |

Galvanized | |

Quality authentication | ISO 9001:2000 |

Material | Q195-Q345 |

Usage | Support roof |

Warehouse/ factory wall/ makeshift house | |

Shape | C section shape ,U section shape, Z section shape |

Productivity | 400 MT/ month |

Min Order Quantity | 10MT |

Delivery Time | 15-20 days after receipt of down payment |

Packing | Bulk pack |

According to the requirement | |

Notice | Special order can be accept and we will offer high quality but low price's products |

Company Information

Our company has established for many years and cooperated with many foreign company. Our company has a professional cold bending forming production line ,annual production of 10000 tons of all kinds of high quality steel ,like Galvanized Cold Formed Channel Steel . Our company’s aim is good quality, low price and short delivery time Galvanized Cold Formed Channel Steel are also called cold bending section steel. As manufacture, we can supply various models, specifications and varieties of cold formed steel. Galvanized Cold Formed Channel Steel has been widely used in building, engineering, automobile requirement, home and office furniture, storage racks. Our products has the following advantages:

1.As a manufacture, we can control our cost. So our price is more reasonable than other's

2.Manufacturing scope: thickness from 1mm to 12mm

3. Size: As per customer's requirement

4. Our factory located in Tangshan city which is near to Tianjing port.

If you have any need, please do not hesitate to contact me. I will try my best to serve you.

2015 Hot Sell Galvanized Cold Formed Channel Steel Pictures

- Q: Are steel channels suitable for electrical conduit systems?

- Certainly, electrical conduit systems can be well-suited for steel channels. The strength and durability of steel channels make them perfect for offering support and safeguarding electrical wiring. They excel at directing and arranging electrical cables within a building or structure. Furthermore, steel channels exhibit resilience in unfavorable environmental conditions, such as extreme temperatures or moisture exposure, contributing to their appropriateness for electrical conduit systems. Nevertheless, ensuring proper grounding and insulation of the steel channels is vital to avoid any electrical risks or interference.

- Q: Can steel channels be used for overhead crane systems?

- Yes, steel channels can be used for overhead crane systems. Steel channels provide the necessary strength and stability required for supporting the weight and movement of overhead cranes, making them a suitable choice for such systems.

- Q: Are steel channels suitable for industrial applications?

- Steel channels are an excellent choice for industrial applications due to their high suitability. Made from top-quality steel, they are renowned for their strength, durability, and versatility. Capable of withstanding heavy loads, they provide structural support in a range of industrial settings. Commonly used in the construction of buildings, bridges, warehouses, and factories, steel channels are also extensively employed in the manufacturing and transportation industries for the production of machinery, equipment, and vehicles. Additionally, steel channels can be easily customized to meet specific requirements, available in various sizes, shapes, and thicknesses. Thanks to their outstanding properties and adaptability, steel channels are widely recognized as a dependable and cost-effective solution for industrial applications.

- Q: How do steel channels perform in high-wind areas?

- Steel channels are an excellent choice for structures in high-wind areas due to their strength and durability. Steel is inherently resistant to wind forces and can withstand high winds without significant deformation or failure. The shape of steel channels, which resembles a U or C, also enhances their performance in high winds. The open side of the channel allows wind to pass through, reducing the overall wind load on the structure. This design feature helps minimize the wind-induced pressures, which are particularly important in high-wind areas. Additionally, steel channels are commonly used in conjunction with other structural components, such as beams and columns, to create a robust framework that can withstand the wind's force. These components are often bolted or welded together, providing a strong connection that further enhances the overall performance in high-wind areas. Moreover, steel channels can be fabricated to meet specific project requirements, allowing for customization and optimization of the structural system. This flexibility ensures that steel channels can be engineered and designed to handle the specific wind conditions of a particular location. It is worth noting that the performance of steel channels in high-wind areas also depends on other factors, such as the design of the overall structure, the quality of construction, and adherence to building codes and standards. Proper engineering and construction practices, including appropriate connections and anchoring, are crucial to ensure optimal performance and safety in high-wind areas. In summary, steel channels are highly reliable and effective in high-wind areas due to their inherent strength, shape, and ability to be customized. When properly designed and constructed, steel channels provide a durable and robust solution for structures in regions prone to strong winds.

- Q: Can steel channels be used for mezzanine floors?

- Yes, steel channels can be used for mezzanine floors. Steel channels are commonly used as a structural component in mezzanine floor construction due to their strength and durability. They provide the necessary support and stability required for creating additional levels or platforms within a building.

- Q: What are the common safety considerations in the design of steel channels?

- Some common safety considerations in the design of steel channels include ensuring proper load-bearing capacity, structural stability, and resistance to deformation or buckling under applied loads. Additionally, factors such as corrosion resistance, fire resistance, and overall durability are also important to ensure the long-term safety and performance of steel channels. Adequate measures must be taken to prevent any potential hazards related to sharp edges, exposed fasteners, or other potential injury risks. Proper installation techniques and adherence to industry standards and codes are essential to ensure the safety of steel channel systems.

- Q: Do steel channels have any specific acoustic properties?

- Steel channels, like any other material, have specific acoustic properties that can affect sound transmission and reflection. The acoustic properties of steel channels are primarily determined by their density, stiffness, and surface characteristics. One important acoustic property of steel channels is their ability to conduct sound. Due to their high density and stiffness, steel channels can efficiently transmit sound waves. This property is often utilized in applications such as building construction, where steel channels are used to create structural elements that can carry sound from one area to another. Moreover, the surface characteristics of steel channels can influence their acoustic properties. Smooth surfaces tend to reflect sound waves, while rough surfaces can absorb or scatter them. The surface texture of steel channels can be modified to enhance or dampen specific acoustic effects. For example, in some architectural designs, steel channels with textured surfaces are used to reduce echoes and improve sound quality in large spaces. Additionally, the thickness and shape of steel channels can also impact their acoustic properties. Thicker channels generally have better sound insulation properties, meaning they can prevent the transmission of sound waves from one area to another. The shape of the channel can also affect how sound waves travel through it, with different profiles potentially causing alterations in the sound propagation. However, it is important to note that steel channels alone may not possess significant soundproofing capabilities. Additional measures, such as insulation materials, are often combined with steel channels to achieve desired acoustic performance in various applications. In summary, steel channels do have specific acoustic properties that can influence sound transmission, reflection, and insulation. Their density, stiffness, surface characteristics, thickness, and shape all play a role in determining how sound waves behave when interacting with steel channels.

- Q: Can steel channels be used for supporting exterior artwork and sculptures?

- Yes, steel channels can be used for supporting exterior artwork and sculptures. Steel channels provide a strong and durable support structure, capable of withstanding various weather conditions. They offer stability and can be customized to fit the specific requirements of the artwork or sculpture, making them a suitable choice for supporting exterior installations.

- Q: Specification for channel steels used in fork trucks

- Specifications are as follows:25a:250x78x7x1228a:280x82x7.5x12.530a:300x85x7.5x13.5

- Q: Are steel channels suitable for marine applications?

- Yes, steel channels are suitable for marine applications due to their high strength, durability, and corrosion resistance properties. They can withstand the harsh marine environment, including exposure to saltwater, making them ideal for various marine structures such as shipbuilding, offshore platforms, and marine infrastructure.

Send your message to us

Galvanized Cold Formed Channel Steel 2015 Hot Sell

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords