Galvanized C Channel Metal Stud Sizes for Drywall

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 g/m

- Supply Capability:

- 300000 g/m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

purlin and wall beam of steel structure building

The C-shaped purlins have excellent anti-bending property and are easy to install. They are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on.

Product Advantages:

1.We have 120 light steel keel machine,one machine for one specification only,to increase the precision of process.

2.We have over 22 years experiency in producing light gague steel frame.

3.We have business trip to the world each year to have better understanding of the trend of local market.

Main Product Features:

1). Commponents: main tee, long cross tee, short cross tee and wall angle.

2). Unique click design for easy connection.

3). Widely usage for the suspension system of hotel, school, hospital, shopping mall, etc.

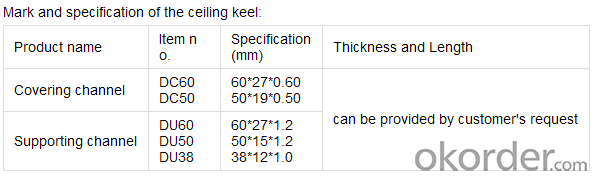

Product Specifications:

Images:

- Q: Light steel keel wall how to install glass door

- In the cut off, with 20 * 20 or 25 * 25 galvanized iron pipe welded into the design of the size of the box, in the ground, the top of the fixed between the fixed door on both sides of the vertical frame, and then the height of the door plus the same box , Welding beam fixed to the spring on the shaft. ??????? This is to consider the glass door in the abnormal switch will have a huge lateral force, resulting in the door axis prone to displacement.

- Q: Light steel keel cut off the keel and the ground with what fixed?

- Expansion bolt or pad on a layer of blockboard (brush fire anti-corrosion coating) with 50 steel row nail directly on the ground

- Q: Is it good for brick walls or light walls?

- I suggest you use ceramic tiles, are light materials, you can hang light items (nails to be stuck in the gray seam, when the walls of the bottom of the three tiles should also use red brick, waterproof). If you have a fire on the request that use the gas block, red brick, lime sand brick, you can hang some of the items.

- Q: What is the decoration of the wall? Lightweight bricks Or light steel keel frame?

- Decorate the wood keel can be, and then use the integrated wall covered up on it. The other keels are too much trouble and time.

- Q: Gypsum board wall above the good paint glass?

- Gypsum board partition wall construction operation process: (1) According to the design drawings, in the already done walls, floors, the ground release off the line, the door hole edge. (2) according to the design drawings and the actual size, with a wheel cutting machine cutting keel and classified stacking. (3) according to the line has been put away and the door edge, with nails or expansion bolts to the ground keel fixed on the ground floor, nail or expansion bolt spacing 600mm. The top of the keel into the wall of the reserved hole 100mm, and then use cement mortar packing fixed, or with nails, expansion bolts to the end of the handle along the top keel fixed to the wall. (4) According to the cut line and the edge of the door, according to the size of the file size layout, painted in the edge, along the top keel, less than the modulus should be placed in the partition with the wall at the first board. (5) According to the document mark will be cut in advance of the length of the vertical keel in turn inserted along the edge, along the top keel groove, the flange towards the direction of the proposed panel to be installed. Adjust the vertical, positioning accuracy, with rivets fixed. The vertical keel on the wall is fixed to the wall with a nail or expansion bolt, and the distance between the nail or the expansion bolt is 1m. (6) the installation of doors and windows to strengthen the installation of the keel: the first installation of the hole on both sides of the vertical reinforcement keel, and then install the hole up and down to strengthen the keel, and finally install the big hole on both sides of the upper and lower reinforcement keel and bracing. (7) Install the cross brace and support card. The vertical keel fastened, so that the entire partition keel has sufficient strength and stiffness.

- Q: Light steel keel + gypsum board + surface brush latex paint partition wall per square meter offer is how much?

- Different local prices are different, but now artificial up, 150 may not find, there is a problem, that is, those who labor market, in general, the level is quite not how!

- Q: What kind of new material is now called a "light partition" in the house? Is it safe?

- As for the sound insulation performance, and not because of the wall is light and affected, but higher than the national noise standards, light steel keel of the outer package with noise pad, can play a very good sound insulation, and the same thickness of the concrete slab The sound insulation of the partition is only 32 decibels. According to the authority test, light steel keel inorganic composite board partition can block the noise reduction of about 38 dB, significantly higher than the international standard of 30 dB, more to ensure the comfortable living needs of living.

- Q: How to do woodworking partition wall, with door

- Wood keel partition wall is made of red, white pine do skeleton, gypsum board or wood fiber board, plywood for the panel of the wall, its processing speed, low labor intensity, light weight, sound insulation effect is good, widely used.

- Q: Do the decoration of the brethren, I would like to ask: inside the plant to do light steel keel ceiling, partition (are ordinary), package the price of how much?

- Now the fee is relatively high, but their own buying and too much trouble

- Q: Shanghai Light Steel keel ceiling Shanghai plant decoration office building decoration light steel keel ceiling wall

- Effective space division The internal space of the plant is mainly divided by the operator according to their actual use requirements to make reasonable use of space, if the plant has a large number of equipment, it is not appropriate to set too much partition and partition, as far as possible to the ground color or with some Color identification to the division of the region, with the identification of the area to avoid too much color, so not only the regional division is not obvious also feel dizzy, and some plants can be clearly divided into the equipment area and office area, such a plan It is now more common because it is easy to manage. Then in the design of such a plant must master the data and the close combination of space, but also take into account the equipment area and the working area of the work area is smooth and dust, noise interference.

Send your message to us

Galvanized C Channel Metal Stud Sizes for Drywall

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 g/m

- Supply Capability:

- 300000 g/m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords