Stud Chinese C Channel Metal Stud Size Drywall

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 g/m

- Supply Capability:

- 300000 g/m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel, adopting laminose strut channel by Cold-formed Technology, are a kind of metal framework made after several continuous rolling. Ceiling keel and wall channel has light-weight, high-intensity, good-antisepsis and other advantages. They mainly match to paperbacked plasterboard and other goods, also the other plates such as GRC, FT and so on.

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building, bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1.Our products’ raw material is highquality hot dipped zinc galvanized steel strip, absolute fireproof and heatinsulation, waterproof and antirust, anticorrosive , high durability

2. Hot dipped zinc galvanized steelstrip zinc coating is 80-180g/m2.

3.Selling well in Middle East , Africa ,Australia, Malaysia ,and America , where the products haveenjoyed an excellent reputation with high quality and services

4. We canprofessionally manufacture the special specification products for customers

5.Advanced equipment and technology can make sure the products exactly size, high quality

Main Product Features:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the keels' vertical points and intensity.

(4) The metal stud with hole : one of our product is the special hole on C-stud every 600mm, which is easy for workers to install the electric lines and water tubes.

(5) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..We can meet your customized demands.

(6) Factory direct sale price : We have our own factory to produce raw materials----galvanized(zinc coated) steel, as well as the product line, so we can provide you a lowest price.

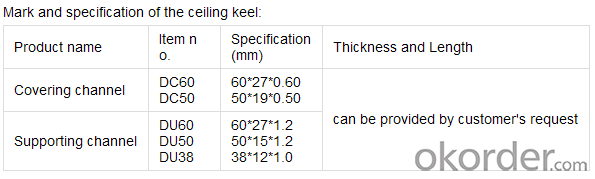

Product Specifications:

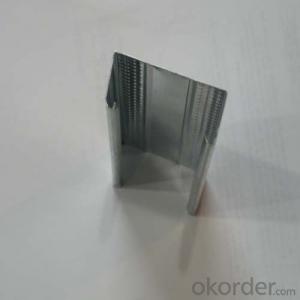

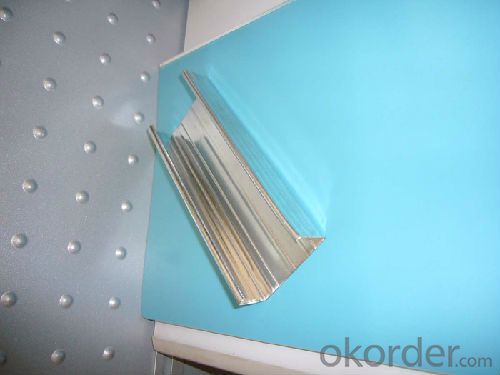

Images:

- Q: Light steel keel wall how to install glass door

- In the cut off, with 20 * 20 or 25 * 25 galvanized iron pipe welded into the design of the size of the box, in the ground, the top of the fixed between the fixed door on both sides of the vertical frame, and then the height of the door plus the same box , Welding beam fixed to the spring on the shaft. ??????? This is to consider the glass door in the abnormal switch will have a huge lateral force, resulting in the door axis prone to displacement.

- Q: The room to remove the partition, can not retain the original light steel keel gypsum board ceiling?

- The room to remove the partition, you can retain the original light steel keel gypsum board ceiling.

- Q: Home to decorate the ceiling, playing the wall, I learned from the market can be resistant, dragon card, Saint Gobanchenko these brands of light steel keel gypsum board which good point?

- You said these are very good brand, Saint-Gobain and Long card companies with more. The material is on the one hand, the ceiling is the most important woodworking craft and craftsmanship. Material is not a problem

- Q: What is the decoration of the wall? Lightweight bricks Or light steel keel frame?

- Well, I think so, I found two companies were quoted, the price is almost, but the listed materials are not the same.

- Q: Can my light steel keel ceiling withstand the weight?

- Light steel keel with superior and non-superior type. 50 light steel keel is not on the man's 50mm * 19mm * 0.5mm man's 50mm * 20mm * 0.6mm main keel man 60 * 27 * 1.2. In addition, the keel of the outer keel does not require less than 600 * 600, and the mandarin keel is usually not less than 400 * 400 according to the load. Compare your material to see what specifications the keel is. Baidu may wish to look at these two types. If it is superior type, there is no problem

- Q: How to fix the middle of the light steel keel to the roof and the ground, the keel has a joint?

- Keel fixation requires the use of expansion bolts fixed, but now many practices are directly linked with steel nails, so more convenient, the effect is almost, of course, is not good with expansion bolts. Top and bottom with 75 days keel. Then there are 75 vertical keels.

- Q: Has installed a wooden floor, you can do in the above light steel keel wall?

- Do of course But I suggest do not do it! You do not want to move the floor, you put the floor cut off the partition of the piece. Directly to the disadvantages: 1: wooden floor flexible, partition instability. 2: you are not bad when the wall and the floor shut. 3: sound insulation is certainly worse

- Q: 9 + 9 double gypsum board is what it means

- Gypsum board is a kind of material made of building gypsum as the main raw material. It is a light weight, high strength, thinner thickness, easy processing and insulation and fire insulation and other properties of better building materials, is currently focused on the development of one of the new lightweight sheet. Gypsum board has been widely used in residential, office buildings, shops, hotels and industrial plants and other buildings within the wall, wall panels (instead of wall plaster layer), ceilings, sound-absorbing panels, ground floor boards and the Such as decorative plates. Gypsum board gypsum board (divided into ordinary gypsum board (commonly used), fiber gypsum board, gypsum decorative plate "interpretation") it to gypsum as the main material, adding fiber, adhesive, modifier, Dry from. With fire, noise, heat, light, high strength, low shrinkage and other characteristics and good stability, not aging, anti-moth, available nails, saws, planing, sticky and other methods of construction.

- Q: Curved gypsum board wall technology.

- Curved (sub-bumps) of the construction method: the first with the blockboard to make the first arc, in the right place with keel (wood keel, light steel keel can be) to shape the joinery board, and then gypsum board Attached to the blockboard and keel on the line. The following figure is the arc (concave) top of the grass-roots approach, curved wall practice with it the same.

- Q: Gypsum board wall is generally done to the height of the original roof or do the height of the ceiling?

- With the requirements of the party, both methods are to do, to sound or privacy is good point, then we must be separated from the top, to save money and then save money on the next day it can be on the next day.

Send your message to us

Stud Chinese C Channel Metal Stud Size Drywall

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 g/m

- Supply Capability:

- 300000 g/m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords