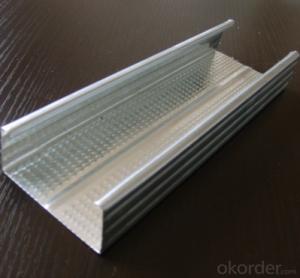

Galvanised Light Steel Profiles for Drywall Decortion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanised Light Steel Profiles for Drywall Decortion

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized stee strip zinc coating is 80-180g/m2.

3.Warm sales in Middle East , Africa , Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services

4. The specification can follow up customer requirments.

5. Advanced equipment can make sure exactly size, high quality products.

Detail description

Drywall 35*22*12*68, thickness 0.45mm - 1.0mm,length 2.8mm,2.9mm,3mm

Drywall channel system some sizes as follows:

a) Stud:

70x35x3000x0.45/0.5/0.6mm

50x35x3000x0.45/0.5/0.6mm

b) Track:

72x25x3000x0.45/0.5/0.6mm

50x25x3000x0.45/0.5/0.6mm

Furring ceiling system some sizes as follows:

a) Furring channel: 35x22x12x300x0.45/0.5/0.6mm

b) Main channel: 38x10(12)x3000x0.45/0.5/0.6mm

c) G.I. Wall angle:

25x25x3000x0.45/0.5/0.6mm

23x23x3000x0.45/0.5/0.6mm

22x22x3000x0.45/0.5/0.6mm

20x20x3000x0.45/0.5/0.6mm

Function and advantage

1.good quality, hot dip galvanized steel coil

2.light weight , easy install

3.surface: zinc coat, full with dot, high strength

4.strong bearing capacity, ametabolic

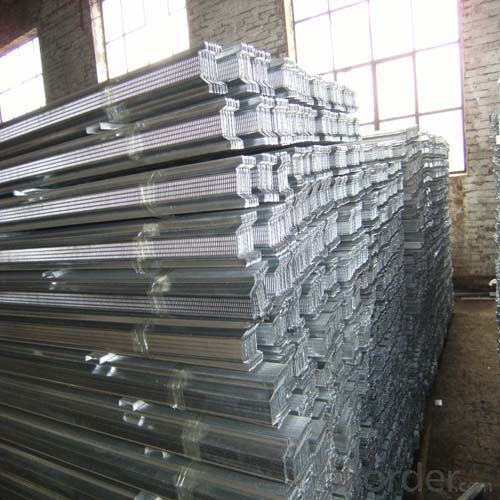

5.the production ability strong, 21 production lines-3200 tons per month

6.meet the GB standard

Package and delivery time

Packing-- 10pcs/bundle, nude package with plastic strip

MOQ- 10tons, can negotiate

Delivery time-- commonly 2 weeks after received the 30% deposit

Application

1,Supermarket, marketplace

2,Underground, air port, bus station

3,Building lobby,metro station

4,Hotel, restaurant,railway station

5,School, office, meeting room ,hospital

6.commercial building

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures:

- Q: The designer said the solid wood flooring keel hit the prefabricated board after the lack of effort in the future may not be strong?

- Do the wall of the best use of light steel keel or wood keel, gypsum board on both sides, in order not to appear cracks, the walls must be posted, try to choose a better texture of the wall cloth and white latex, if the conditions can use the grid Cloth, the relative crack effect will be better. Prefabricated board floor is a designer that the problem can be used in the floor with cement leveling, thicker after playing keel.

- Q: Now what is the room wall material is fashionable? Environmentally friendly

- Now home improvement wall materials are generally light steel keel + sound insulation cotton and light brick wall two, two have their own advantages and disadvantages, brick wall thickness, and space, sound insulation and no sound insulation board is good ; Light steel keel plus gypsum board cut off the knock will be pound, but if it is to consider the bedroom wall after the TV, then the best use of light steel keel + noise cotton, because the hanging must be hanging on the keel, or hanging The In addition, can also be resistant to sound insulation board, thinner board sound insulation effect is better, but the price is relatively expensive. General high noise requirements such as the hotel is used in such a soundproof board.

- Q: What is the light steel keel gypsum board partition? What are the characteristics?

- 1. Wall shrinkage deformation and board cracks: the reason is the vertical keel tight top and bottom keel, no extension of the amount of stretch, more than 2m long wall is not controlled deformation joints, resulting in wall deformation. The wall should be left around the gap 3mm, which can reduce the temperature and humidity caused by the deformation and cracks. 2. Light steel skeleton connection is not strong, because the local node does not meet the structural requirements, the installation of local nodes should be strictly in accordance with the provisions of the law. Nail spacing, location, connection method should meet the design requirements.

- Q: Gypsum board wall above the good paint glass?

- Gypsum board partition wall construction operation process: (1) According to the design drawings, in the already done walls, floors, the ground release off the line, the door hole edge. (2) according to the design drawings and the actual size, with a wheel cutting machine cutting keel and classified stacking. (3) according to the line has been put away and the door edge, with nails or expansion bolts to the ground keel fixed on the ground floor, nail or expansion bolt spacing 600mm. The top of the keel into the wall of the reserved hole 100mm, and then use cement mortar packing fixed, or with nails, expansion bolts to the end of the handle along the top keel fixed to the wall. (4) According to the cut line and the edge of the door, according to the size of the file size layout, painted in the edge, along the top keel, less than the modulus should be placed in the partition with the wall at the first board. (5) According to the document mark will be cut in advance of the length of the vertical keel in turn inserted along the edge, along the top keel groove, the flange towards the direction of the proposed panel to be installed. Adjust the vertical, positioning accuracy, with rivets fixed. The vertical keel on the wall is fixed to the wall with a nail or expansion bolt, and the distance between the nail or the expansion bolt is 1m. (6) the installation of doors and windows to strengthen the installation of the keel: the first installation of the hole on both sides of the vertical reinforcement keel, and then install the hole up and down to strengthen the keel, and finally install the big hole on both sides of the upper and lower reinforcement keel and bracing. (7) Install the cross brace and support card. The vertical keel fastened, so that the entire partition keel has sufficient strength and stiffness.

- Q: Waterproof gypsum board for toilet partition and paste tile installation steps?

- Bathroom wall on the calcium silicate board filled with less than 3CM steel mesh; fixed with a code nail gun; and then use 1: 3 of the cement mortar smear 2-3CM thick. After leveling the hair according to the normal process of paving wall.

- Q: Light steel keel wall and wood which low cost

- If you are in the home decoration inside the words, the cost of this level is negligible. And if the area is relatively large, then the use of light steel keel production wall, there will be a clear advantage. Light steel keel production of the wall, its performance is relatively stable, wood products can not be compared.

- Q: Decorative light steel keel paper gypsum board wall height of 4.1 meters span 6.5 meters need not add structural column, beam

- If there is no stiffness requirement for the wall, there is no need to increase. If there is such a request, it is necessary to increase the minimum of three steel square pillars and two steel square cross.

- Q: What kind of new material is now called a "light partition" in the house? Is it safe?

- Light steel keel inorganic composite board partition is a high toughness material, compared to the traditional partition, better shock resistance. In the simulation of super 8 earthquake experiment, the traditional block wall has long been decomposed collapse, but the light steel keel inorganic composite board wall is still solid and reliable, showing its seismic capacity far more than the traditional wall, which is light steel Keel inorganic composite board partition in Japan widely used reasons, security is the primary consideration of residential construction factors.

- Q: Light steel keel installed security door how loaded really

- It is recommended to install two square steel pipes vertically and fixed on the concrete floor and floor. The security door is mounted on the square steel pipe

- Q: Gypsum board wall is generally done to the height of the original roof or do the height of the ceiling?

- With the requirements of the party, both methods are to do, to sound or privacy is good point, then we must be separated from the top, to save money and then save money on the next day it can be on the next day.

Send your message to us

Galvanised Light Steel Profiles for Drywall Decortion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords