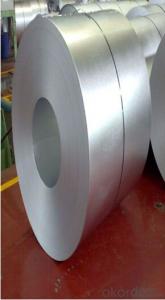

hot dipped galvanized steel sheet in coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thickness | 0.125-0.8mm |

Width | 750-1250mm |

Zinc coating | 50-220g/m2 |

Type | steel coil |

Weight of each package | 3-5mt |

Technology | cold rolled |

Material | SPCC Q195 SGCC SGCH |

Standard | ASTM,GB,JIS,DIN |

ID | 508mm |

Price | FOB XingangUSD800-1200 per mt |

Packing | seaworthy export packing or mill's standard packing or as per client's request. |

Surface treatment | galvanized,passivated,skin pass,bright finished,corrosion resistance.

|

Delivery time | within 35 days after receiving the down payment or irrevocable L/C at sight

|

Payment | 30% down payment of the total value by T/T and the balance must be paid by T/T or irrevocable L/C at sight after the goods finished. |

Application | widely used in construction,household appliance,automobile,light industry,etc. |

- Q: Can steel sheets be used for electrical grounding purposes?

- Yes, steel sheets can be used for electrical grounding purposes. Steel is a good conductor of electricity, which makes it suitable for grounding applications. When properly connected to an electrical system, steel sheets can provide an effective path for the dissipation of electrical charges and prevention of electrical shock hazards. However, it is important to ensure that the steel sheets are adequately bonded and connected to the grounding system in order to create a low-resistance path for fault currents. Additionally, factors such as the thickness and surface area of the steel sheets should be considered to ensure they meet the requirements for effective grounding.

- Q: Can steel sheets be used for soundproofing applications?

- No, steel sheets are not typically used for soundproofing applications as they are not effective in blocking or reducing sound transmission.

- Q: Can the steel sheets be used for kitchen countertops?

- Yes, steel sheets can be used for kitchen countertops. Steel is a durable and long-lasting material that can withstand high temperatures, making it suitable for kitchen use. It is resistant to stains, scratches, and water damage, making it easy to clean and maintain. Additionally, steel countertops can provide a sleek and modern aesthetic to any kitchen. However, it is worth noting that steel can be prone to scratches and dents, so it is important to exercise caution when using sharp utensils or heavy objects on the countertop.

- Q: Why should the back of the steel sheet pile cofferdam be pumped after the construction of the pile cap?

- Loading and unloading steel sheet piles should be operated by two points lifting method. The number of steel pile piles should not be too many at any time, and attention should be paid to the protection of the locking hole to avoid damage.

- Q: What is the maximum length of steel sheets?

- The maximum length of steel sheets can vary depending on the manufacturer and specific application, but it is typically around 40 feet (12 meters) for standard commercial steel sheets.

- Q: Can steel sheets be used for industrial machinery parts?

- Yes, steel sheets can be used for industrial machinery parts. Steel is a commonly used material in the manufacturing industry due to its strength, durability, and versatility. Steel sheets can be fabricated and shaped to meet the specific requirements of machinery parts, making them suitable for various industrial applications.

- Q: What is a cold rolled sheet with plastic sprayed?

- After the cold rolled steel sheet is finished, the surface treatment needs to be carried out, including:1: electroplating: zinc plated, nickel plated, copper plated, gold plated, chrome plated,2: immersion plating: black, hot galvanizing3: spray: spray paint, spray, baking paint,4: polishing, point solution polishing, shot peening, shot blasting

- Q: Can steel sheets be used for cladding or facade systems?

- Yes, steel sheets can be used for cladding or facade systems. Steel is a durable and versatile material that offers excellent structural support and weather resistance. It can be shaped into various profiles and finishes, making it suitable for creating aesthetically pleasing and functional building facades.

- Q: Are steel sheets suitable for high-temperature insulation?

- No, steel sheets are not suitable for high-temperature insulation as they conduct heat rather than insulate against it.

- Q: What are the different sheet metal welding techniques for steel sheets?

- There are several sheet metal welding techniques commonly used for steel sheets, including spot welding, seam welding, and TIG welding. Spot welding involves joining two metal sheets by applying pressure and heat at specific points, creating a strong bond. Seam welding, on the other hand, involves continuously welding along the length of a joint, creating a continuous welded seam. TIG welding, also known as tungsten inert gas welding, uses a non-consumable tungsten electrode to create an arc that melts the metal, forming a weld pool that fuses the steel sheets together. Each technique has its own advantages and is chosen based on the specific requirements of the project.

Send your message to us

hot dipped galvanized steel sheet in coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords