Gabion Boxes/Stone Cages/Gabion Basket With Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

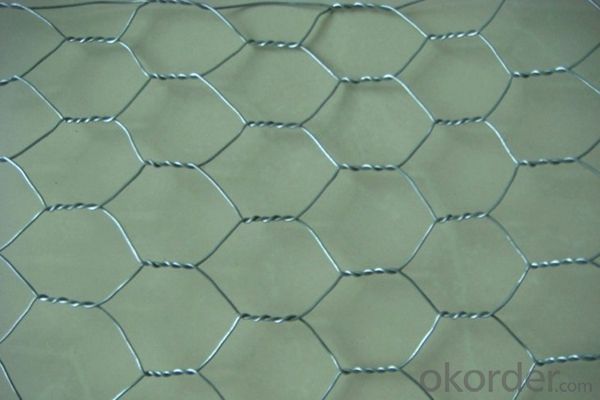

1:Gabion Box Materials

1.Galvanized steel wire :low carbon steel wire

2.Zinc-5% aluminum-mixed mischmetal alloy steel wire ,a new-type material

3.Galvanized steel wire ,PVC or PE coating

2:Gabion Box Process

wire drawing---galvanized--- galvanized after weaving or galvanized before weaving.

3:Gabion Box Packing

50-100 gabion wire mesh /per bundle,wrapped with 2 to steel strips

4:Gabion Box Payment term

30% T/T in advance as deposit and 70% balance upon delivery.

5:Gabion Box Delivery time

20 days after receive the deposit

6:Gabion Box Color

PVC coated hexagonal wire mesh is green, white, grey or other colors; enamelled hexagonal wire mesh is green.

7:Gabion Box Features

1.It is very economical . You just need to put stone in the mesh and then seal it .

2.It is flexible ,corrosion resistant and can stand up to extreme weather.

3.Simple construction,requiring no special technique.

4.The silt between the wire mesh and stone contributes to plant growth.this makes the gabion wire mesh harmoni ous with the surrounding natural environment .

5.The gabion wire mesh is folding and can be assembled site,which saves on transport cost.

8:Gabion Box Details Specification

Opening (mm) | Wire Diameter (mm) | Wire Diameter(PVC Coated) Inner/outside(mm) | Strands |

60x80 | 2.0-2.8 | 2.0/3.0-2.5/3.5 | 3 |

80x100 | 2.0-3.2 | 2.0/3.0-2.8/3.8 | 3 |

80x120 | 2.0-3.2 | 2.0/3.0-2.8/3.8 | 3 |

100x120 | 2.0-3.4 | 2.0/3.0-2.8/3.8 | 3 |

100x150 | 2.0-3.4 | 2.0/3.0-2.8/3.8 | 3 |

120x150 | 2.0-4.0 | 2.0/3.0-3.0/4.0 | 3 |

Gabion Size(m) | Mesh Model | |||||

8x10 | 6x8 | |||||

Length | Width | Height | Gal. or PVC coated | Gal. or PVC coated | ||

Mesh wire diameter | Gal. weight | Mesh wire diameter | Gal. weight | |||

2m | 1m | 1m | 2.7mm | >245g/m2 | 2.0mm | >215g/m2 |

3m | 1m | 1m | Selvedge wire diameter | Gal. weight | Selvedge wire diameter | Gal. weight |

4m | 1m | 1m | 3.4mm | >265g/m2 | 2.7mm | >245g/m2 |

6m | 1m | 1m | Lacing wire 2.7mm | Lacing wire 2.0mm | ||

9:Gabion Box Application

Welded gabion mesh is widely used for the control and guide of water; preventing of rock breaking; water and soil, roadway and bridge protection; strengthening structure of soil; protection engineering of seaside area and retaining wall structures; hydraulic structures, dams and culverts; coastal embankment works; architectural feature retaining walls.The main application as follows:

a. Control and guide of water or flood

b. Flood bank or guiding bank

c. Preventing of rock breaking

d. Water and soil protection

e. Bridge protection

f. Strengthening structure of soil

g. Protection engineering of seaside area.

- Q: How is steel wire mesh used in reinforcement of mining projects?

- Steel wire mesh is used in the reinforcement of mining projects by providing structural support and preventing the collapse of tunnels, shafts, and other underground structures. It helps to distribute the load evenly, enhance stability, and prevent the movement of loose rocks or debris. Additionally, steel wire mesh can reinforce the walls of mines to protect against rock falls and provide safety for miners.

- Q: What are the benefits of using steel wire mesh in the automotive recycling industry?

- There are several benefits of using steel wire mesh in the automotive recycling industry. Firstly, steel wire mesh is extremely durable and strong, making it suitable for handling heavy objects and materials. This is particularly important in the automotive recycling industry, where large and heavy parts need to be sorted, separated, and transported. Steel wire mesh can withstand the weight and pressure of these parts without getting damaged, ensuring a safe and reliable operation. Secondly, steel wire mesh is highly resistant to corrosion. As the automotive recycling industry deals with various materials, including those that may contain chemicals or fluids, the risk of corrosion is high. However, steel wire mesh's resistance to corrosion ensures a longer lifespan, reducing the need for frequent replacements and saving costs in the long run. Moreover, steel wire mesh is versatile and can be customized to fit specific requirements. Automotive recycling facilities often have unique needs in terms of size, shape, and design of their sorting and separation equipment. Steel wire mesh can be easily fabricated and tailored to meet these specific needs, allowing for efficient and effective operations. Additionally, steel wire mesh is easy to clean and maintain. In the automotive recycling industry, where debris, dust, and fluids are common, regular cleaning is essential to maintain a hygienic working environment. Steel wire mesh's open design allows for easy access and cleaning, ensuring a clean and safe workplace. Lastly, steel wire mesh is environmentally friendly. As the automotive recycling industry focuses on reducing waste and promoting sustainability, using steel wire mesh aligns with these goals. Steel wire mesh is recyclable, meaning it can be reused or repurposed after its lifespan in the industry, reducing the overall environmental impact. In conclusion, the benefits of using steel wire mesh in the automotive recycling industry include durability, corrosion resistance, versatility, ease of maintenance, and environmental friendliness. These advantages contribute to a more efficient and sustainable operation, making steel wire mesh an ideal choice for automotive recycling facilities.

- Q: Can steel wire mesh be galvanized?

- Yes, steel wire mesh can be galvanized. Galvanization is a process of applying a protective zinc coating to steel to prevent corrosion, and it can be done on various steel products, including wire mesh.

- Q: What are the acoustic properties of steel wire mesh?

- Steel wire mesh has several acoustic properties. It has a high level of sound transmission due to its open structure, allowing sound waves to pass through easily. However, it also has the ability to scatter and diffuse sound waves, reducing their intensity and creating a more balanced acoustic environment. Additionally, steel wire mesh can act as a barrier to block certain frequencies of sound, providing some level of sound insulation. Overall, the acoustic properties of steel wire mesh make it a versatile material for various applications in sound control and acoustic design.

- Q: How is steel wire mesh used in reinforcement of concrete columns?

- Steel wire mesh is used in the reinforcement of concrete columns by providing additional tensile strength to the structure. The mesh is placed within the concrete during the pouring process, and it helps to prevent cracking and improve the overall durability and load-bearing capacity of the columns.

- Q: Is steel wire mesh suitable for use in electrical enclosures and panels?

- Yes, steel wire mesh is suitable for use in electrical enclosures and panels. It provides a strong and durable barrier that allows for proper ventilation and heat dissipation while offering protection against physical damage and unauthorized access. Additionally, the open design of the mesh allows for easy visibility and access for maintenance and troubleshooting purposes.

- Q: Can steel wire mesh be used for creating gabion walls?

- Yes, steel wire mesh can be used for creating gabion walls. Gabion walls are structures made by filling large wire mesh baskets with rocks, stones, or other materials. The steel wire mesh used for gabion walls is typically made from high-quality, corrosion-resistant steel to ensure durability and longevity. The mesh is tightly woven to create a strong and sturdy structure that can withstand external pressures. The mesh baskets are filled with rocks or stones, and the interlocking mechanism of the mesh holds the materials in place, creating a stable wall. Steel wire mesh is a popular choice for gabion walls due to its strength, flexibility, and ability to resist environmental factors such as erosion and water flow. It is also cost-effective and relatively easy to install. Overall, steel wire mesh is an excellent option for creating gabion walls as it provides the necessary structural stability and aesthetic appeal required for various landscaping, erosion control, and civil engineering projects.

- Q: Can steel wire mesh be used for statues?

- Yes, steel wire mesh can definitely be used for statues. Steel wire mesh is a versatile material that can be shaped and manipulated into various forms, making it suitable for creating intricate and detailed sculptures. It offers structural support and stability, allowing sculptors to create larger and more complex statues. Additionally, the open design of the mesh allows for transparency, which can create interesting visual effects when combined with other materials or lighting. Steel wire mesh is also durable and weather-resistant, making it ideal for outdoor statues that need to withstand the elements. Overall, steel wire mesh offers sculptors a wide range of possibilities when it comes to creating statues, making it a popular choice in the art world.

- Q: What are the safety precautions for handling steel wire mesh?

- When handling steel wire mesh, there are a few important safety precautions to keep in mind. Firstly, it is essential to wear appropriate personal protective equipment, such as gloves and safety glasses, to prevent any injuries or cuts from the sharp edges of the mesh. Secondly, ensure that the work area is well-lit and free from any obstructions or tripping hazards. It is also advisable to use proper lifting techniques and equipment when moving or lifting heavy rolls or sheets of wire mesh to avoid strains or back injuries. Lastly, be cautious when working with power tools or machinery to avoid accidental contact with the mesh, and always follow the manufacturer's instructions and guidelines for safe operation.

- Q: What are the benefits of using steel wire mesh in the electronics industry?

- The use of steel wire mesh in the electronics industry offers several advantages. Firstly, it provides excellent electromagnetic shielding capabilities, effectively blocking or reducing the entry and exit of electromagnetic waves. This ensures the protection of sensitive electronic components from external interference, leading to improved performance and reliability. Secondly, steel wire mesh is known for its high strength and durability. It can withstand mechanical stress, impacts, and vibrations, protecting delicate electronic components from physical damage. This ensures the longevity and reliability of electronic devices. Furthermore, steel wire mesh is highly versatile and customizable. It can be manufactured in various shapes, sizes, and configurations to meet the specific requirements of different electronic applications. This adaptability enhances the functionality and performance of electronic devices and structures. Moreover, steel wire mesh promotes effective heat dissipation by allowing air circulation and ventilation. This is crucial in preventing overheating and subsequent component failure, prolonging the lifespan of electronic devices and preventing performance degradation. Lastly, steel wire mesh offers a cost-effective solution for manufacturers in the electronics industry. Compared to other materials, such as solid metal sheets or plastic enclosures, steel wire mesh is relatively affordable in terms of production and installation costs. In conclusion, the benefits of steel wire mesh in the electronics industry include electromagnetic shielding, strength and durability, versatility, heat dissipation, and cost-effectiveness. These advantages make it an ideal choice for various electronic applications, ensuring reliable and efficient performance.

Send your message to us

Gabion Boxes/Stone Cages/Gabion Basket With Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords