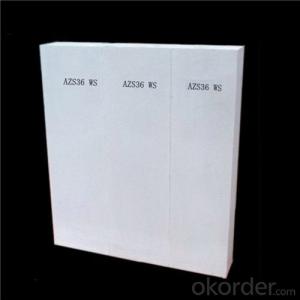

Corundum Brick - Fusion Cast Alumina White Corundum 95% Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

α-β-Al2O3 TY-M has no contamination of glass melt,dense structure,excellent corrosion resistance of glass melt below 1350°C. It is the ideal refractory materials for channels, spouts and working ends of floating glass furnace.

β-Al2O3 TY-H has high temperature,better alkali resistance and excellent thermal stability measuration.It is a new refractory material of float glass furnace of breast wall,Port mouth and top Crown.

α-Al2O3 TY-A :The typical glass contact materials for the end zones of furnaces (working-end, feeder channels) when glass quality is the priority : TV Glass, high quality container glass, float glass.

physical and chemical index:

| Item | Unit | Behaviors | ||||

| FUSED CAST Alumina | ||||||

| TY-M | TY-H | TY-A | ||||

| Chemical Composition | Al2O3 | % | 94 | 93 | 98.5 | |

| SiO2 | ≤ | 1 | 1 | 0.4 | ||

| NaO2 | 4 | 6.5 | 0.9 | |||

| Crystallographic | a-Al2O3 | 44 | 0 | 90 | ||

| b-Al2O3 | 55 | 99 | 4 | |||

| Vitreous Phase | 1 | 1 | 6 | |||

FAQ

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: How much is a refractory brick?

- There are many kinds of refractory bricks, you have to look at what is material, the material is not the same, the price is not the same, clay brick is the cheapest, probably hundreds of dollars a ton, and corundum brick a ton of several money, silicon carbide, silicon nitride, and more expensive. And this thing is generally on t sell, the price is by a single block after conversion.

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

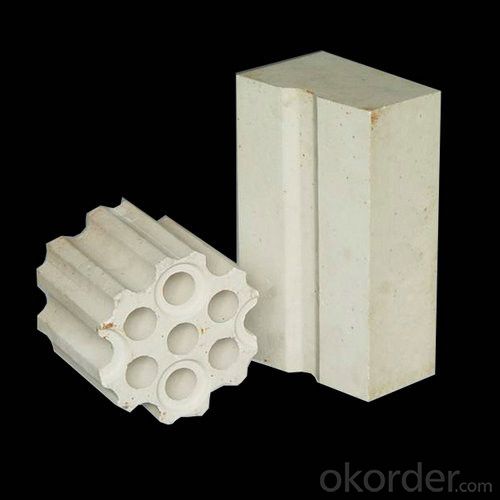

- Fused zirconia corundum brick is pure alumina and zirconia containing silica 65%, about 34% of the zircon sand in electric furnace melting after internalization into moulds cooling and the formation of the white solid, the petrographic structure by zirconium corundum and plagioclase eutectoid and glass phases, from the phase is eutectoid zirconium corundum and plagioclase phase, glass phase filling between their crystallization.

- Q: What is the main component of corundum?

- Corundum is the main component of Al2O3, often containing trace impurities such as Cr, Ti, Fe, V and so on.

- Q: What is the blast furnace ceramic cup called by the refractory factory?

- In fact, a kind of ceramic cup of blast furnace refractories, application in blast furnace bottom and hearth contact steel lining using a layer of non carbon refractory materials, such as Theron with corundum brick, corundum mullite and synthetic mullite bricks etc..

- Q: Which is good, glazed brick and whole cast glazed brick?

- The main advantages of all glazed glazed tiles are that they can be very rich and beautiful in texture and pattern, and they are suitable for family decoration, and can choose patterns according to their own family decoration style. Compared to the glazed tile, it has better pollutant discharge performance, and many pollutants are difficult to penetrate into it.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- For example: 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more. 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q: Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- The sinter plate dust collector is also called plastic plate dust collector. The utility model has the advantages that the utility model can adapt to various complicated working conditions, the dust removal rate is 99.99%, the utility model has the advantages of long service life, stable operation, high temperature resistance, and the utility model is a leading dedusting equipment in china.

- Q: Is liquid phosphoric acid two aluminum hydrogen flammable?

- Liquid phosphoric acid two hydrogen aluminum features: easy mixing, molding, especially suitable for field construction, so liquid phosphoric acid two hydrogen aluminum is not flammable

- Q: What are the main constituents of refractory bricks?

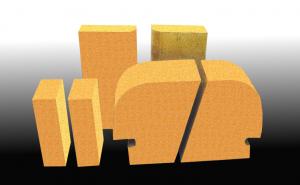

- Refractory brick composition is mainly composed of a variety of aggregate or aggregate and one or more kinds of sticky agent composed of mixed powder particles, when used, must be mixed with one or more liquids, mixing evenly, with strong liquidity. Different refractory bricks are different, such as silicon, aluminum, clay and so on:According to the composition of refractory bricks, they can be divided into five major categories, namely, silicon aluminum refractory bricks, basic series refractory bricks, carbon containing refractory bricks, zirconium containing refractory bricks and insulating refractory bricks. Any furnace is not made of only one kind of refractory brick, and it needs different fire bricks to match with each other. The following five categories of refractory bricks are described in detail.

- Q: Can the fire clay be reused?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

Send your message to us

Corundum Brick - Fusion Cast Alumina White Corundum 95% Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords