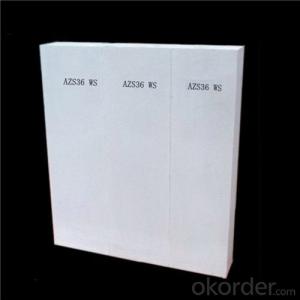

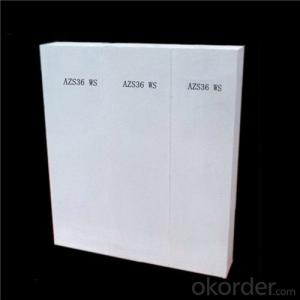

Fused Cast Alumina White Corundum 95% Refractory Bricks

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

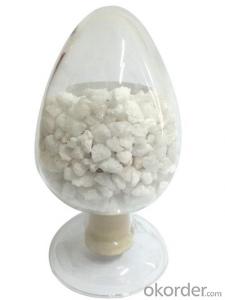

White Fused Alumina

Our WFA grains are produced from high purity calcined or feedstock alumina in electric arc-furnaces. The molten material undergoes cooling, crushing, grinding, sieving, classifying and, of course, various quality checking procedure before it is packed for delivery.

White Fused Alumina product uses

White Fused Alumina is widely used in the refractory industry as it is a very pure low iron alumina suitable for a range of applications. Specific refractory applications include high tech refractory castables, isostatic pressed refractories and pre-cast refractory shapes. The benefits of White Fused Alumina in these applications are that it has a very high alumina content, low impurities and stability at high temperatures.

White Fused Alumina applications

White Fused Alumina typical properties

| Type Index | Low Na WFA | Medium Na WFA | |||||||

| Grit | Fine Powder | Grit | Fine Powder | ||||||

| guarantee value | typical value | guarantee value | typical value | guarantee value | typical value | guarantee value | typical value | ||

| Chemical composition(%) | Al2O3 | ≥99 | 99.38 | ≥99 | 99.23 | ≥99 | 99.24 | ≥99 | 99.12 |

| SiO2 | ≤0.2 | 0.15 | ≤0.3 | 0.22 | ≤0.2 | 0.12 | ≤0.3 | 0.19 | |

| Fe2O3 | ≤0.1 | 0.03 | ≤0.15 | 0.08 | ≤0.1 | 0.04 | ≤0.15 | 0.08 | |

| Na2O | ≤0.25 | 0.18 | ≤0.25 | 0.18 | ≤0.35 | 0.29 | ≤0.45 | 0.33 | |

| Actual Density(g/cm3) | ≥3.92 | ||||||||

| Bulk Density(g/cm3) | 3.4-3.6 | ||||||||

| Apparent Porosity(%) | ≤8 | ||||||||

| Grit Size(mm) | 0-50 F4-F240 ( Other special specifications could be supplied as required ) | ||||||||

| Fine Power(mesh) | -80 -100 -120 -180 -200 -240 -325 ( Other special specifications could be supplied as required ) | ||||||||

| Inspection Standard | GB/T21114-2007 GB/T2999-2002 | ||||||||

FAQ

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: What is brick power, half brick power and full brick power difference?

- Power module. Small size, high power. General use should order additional storage energy, heat dissipation, etc.. Dimensions such as brick, so called brick power supply. Half brick power supply is half the size of all brick power supply.

- Q: What are the categories of bricks?

- In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

- Q: What is the face brick

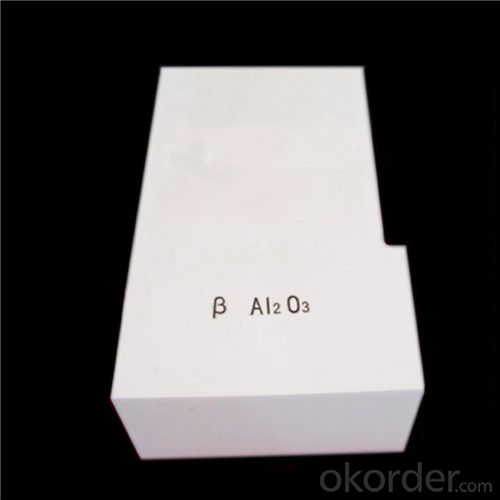

- You should be talking about refractory bricksThe refractory brick brick. Referred to as refractory material has a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick, refractory insulating bricks (Rong Zhuzhuan);

- Q: Just what is in the furnace material?

- Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, brick, brick and other specific type.

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, brick, brick and other specific type. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: What are the main constituents of refractory bricks?

- According to the composition of refractory bricks, they can be divided into five major categories, namely, silicon aluminum refractory bricks, basic series refractory bricks, carbon containing refractory bricks, zirconium containing refractory bricks and insulating refractory bricks. Any furnace is not made of only one kind of refractory brick, and it needs different fire bricks to match with each other. The following five categories of refractory bricks are described in detail.

- Q: Outside wall tile (whole body smooth surface has small hole split brick) has cement pollution, with what product cleaning (cement, mortar, cleaning agent)?

- Tile has a long period of cement pollution, a variety of weak acid cleaning can be removed, such as oxalic acid, acetic acid and so on, of course, the use of special cleaning agent is perfect. But the cost is higher.

- Q: What's the use of refractory bricks?

- Refractory brick fire resistance is greater than 1580 degrees, and the average brick three or four Baidu softened deformation. The refractory brick because of its high refractoriness, and high pressure molding, and after high temperature kiln, so the use of strength is particularly good, practicality is particularly strong in high temperature liquid, gas with high temperature, high temperature solid, chemical corrosion products etc..

- Q: Can the fire clay be reused?

- Refractory soil cannot be reused.Clay refractory soil 1, characteristics and uses: Clay refractory brick is a weak acid refractory material, its thermal stability is good, suitable for hot air furnace, all kinds of boiler lining, and flue, smoke room, etc.. 2, product specifications form: standard shape, general, special-shaped and special-shaped brick. Physical and chemical properties of fireclay bricks.

- Q: What's the weight of the refractory bricks?

- Light weight brick 1 to 1.7 kilograms; heavy clay superscript brick weighs 3.75 kilograms; light 30 plates 0.79 kilograms; light 40 plates, 1.05 kilograms

Send your message to us

Fused Cast Alumina White Corundum 95% Refractory Bricks

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords