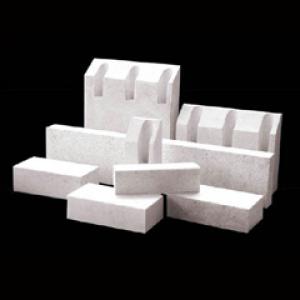

Corundum Brick - Alumina Spinel Refractory Brick with Tough Texture and High Quality of Compression Resistance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

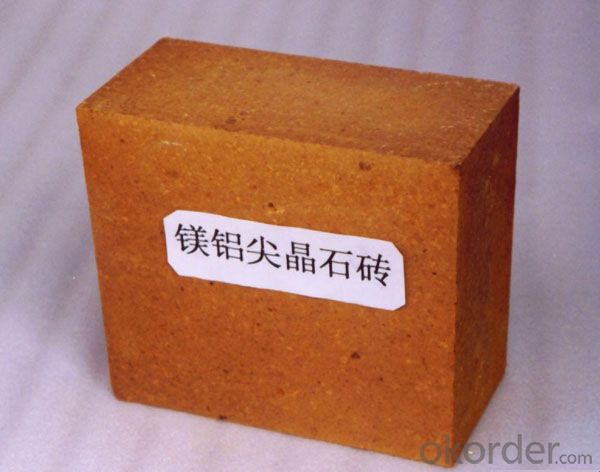

| Place of Origin: | Shandong, China (Mainland) | Shape: | Brick | Material: | magnesite spinel |

| SiO2 Content (%): | 1.2-4 | Al2O3 Content (%): | 6-10 | MgO Content (%): | ≥80 |

| Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | Model Number: | MA | Brand Name: | CNBM |

| A.P.: | ≤ 17% | Bulk density: | ≥ 2.93 g/cm3 | Cold crushing strength (MPa): | >50 |

| Refractoriness under load (℃): | >1610 | Thermal shock resistance (times): | 3~6 | CaO %: | ≤1.5 |

Packaging & Delivery

| Packaging Details: | in wooden pallets |

| Delivery Detail: | 25 days |

Advantage:

It takes good quality fused magnesite and fused mgo-cr clinker as raw material, formed under high pressure,burned in high temperature. It has character of corrosion resistance.

Type:

We can supply High Alumina Bricks, Fireclay Bricks, Low Porosity Fireclay Bricks, Mullite Bricks, Corundum Bricks, AZS Bricks, Magnesite Bricks, Zircon Bricks,insulating Bricks etc.

Application:

Main using for VOD,AOD,SKF,LF,RH etc. secondary refining furnace.

Specification:

FM-MA80 | FM-MA85 | FM-MA90 | |

MgO (%) | 85 | 88 | 90 |

Al2O3 (%) | 7 | 6.5 | 6.5 |

SiO2 (%) | 4 | 2.4 | 1.2 |

CaO (%) | 1.5 | 1.3 | 1.2 |

Fe2O3 (%) | 1.7 | 1.4 | 1.0 |

Apparent porosity (%) | 17 | 17 | 17 |

Bulk density (g/cm3) | 2.93 | 2.93 | 2.94 |

Cold crushing strength (MPa) | 50 | 50 | 55 |

Refractoriness under load (℃) | 1610 | 1650 | 1700 |

Thermal shock resistance (times) | 3~6 | 3~6 | 3~6 |

- Q: Application of electric high temperature regulating valve?

- Acid refractory with silicon oxide (SiO2) as the main ingredient, commonly used are silica brick and clay. Brick is siliceous products containing more than 93% SiO2, the use of raw materials with silica, silica and other waste. The silica acid slag erosion ability is strong, but vulnerable to the erosion of basic slag, its softening temperature is very high, close to the fire, the volume does not shrink after repeated burning, or even a slight swelling, but the thermal shock stability. The brick is mainly used for thermal equipment of coke oven, glass furnace, furnace and other acidic silica brick, according to the physicochemical indexes and SiO2 content can be divided into several levels, mainly used in glass furnace and coke oven silica brick for two categories. Clay brick with refractory clay or bauxite clinker as main raw material, containing 30% to 46% of alumina, refractory degrees 1580 to 1770 DEG C, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used in refractory clay brick clay as main raw material is called common clay brick that made pyrojewel clinker as the main raw material, the porosity in the clay brick below 17% is called low porosity clay brick. Two kinds of clay bricks are divided into several grades according to the physical and chemical indexes. The price difference between the ordinary clay bricks and the low porosity clay bricks is great.

- Q: How much is a thermal brick?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

- Q: How much is a refractory brick?

- There are many kinds of refractory bricks, you have to look at what is material, the material is not the same, the price is not the same, clay brick is the cheapest, probably hundreds of dollars a ton, and corundum brick a ton of several money, silicon carbide, silicon nitride, and more expensive. And this thing is generally on t sell, the price is by a single block after conversion.

- Q: What is the main component of corundum?

- Corundum is the main component of Al2O3, often containing trace impurities such as Cr, Ti, Fe, V and so on.

- Q: What is the blast furnace ceramic cup called by the refractory factory?

- The peak of new materials in various coal, metallurgy, mines, ports, electricity, building materials and military industry, a lot of workpiece and affect production equipment due to wear, wear resistant materials although rarely cause disasters metal workpiece disaster, but the resulting economic loss is immeasurable.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is a kind of refractory material in refractory brick products. It is made of refractory clay or other refractory material. It belongs to the product of Si Al System

- Q: Is liquid phosphoric acid two aluminum hydrogen flammable?

- Liquid phosphoric acid two hydrogen aluminum features: easy mixing, molding, especially suitable for field construction, so liquid phosphoric acid two hydrogen aluminum is not flammable

- Q: How do corundum bricks bind?

- Each refractory brick is provided with corresponding refractory mud, and corundum bricks are bonded with corundum mud.

- Q: Ask for help about the phase of refractory material

- Major crystalline phase. The main crystalline phase is a crystalline phase that constitutes the principal part of the material structure and has a high melting point and a dominant role in the properties of the material. The properties, quantities, distribution and bonding state of the main crystalline phases of refractory determine the properties of the products directly. A lot of refractory products, such as mullite brick, corundum brick, magnesia brick, magnesia spinel brick, silicon carbide refractory products, etc., are the main phase named.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- The T3 in T3 refractory bricks refers to the model indicating that the refractory brick model is T-3, and that the corresponding T-3 model is 230*114*65 (mm)

Send your message to us

Corundum Brick - Alumina Spinel Refractory Brick with Tough Texture and High Quality of Compression Resistance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords