zirconium corundum refractory brick and product

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

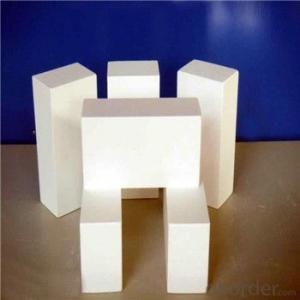

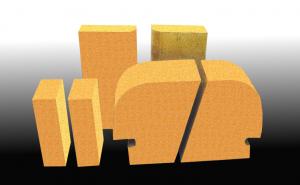

Our zircon brick series products included the alpha Al2O3, partial stability of zirconium dioxide and zirconium material such as alumina clinker as raw material, through mixing, molding, drying, the shuttle kiln high temperature burn becomes.The crystal structure and dense zircon brick products, bulk density, high capacity big, high mechanical strength at room temperature and high temperature, good thermal shock stability performance, reheat shrinkage and high temperature creep decrescent, and high chemical stability and resistance to erosion features such as alkaline medium.Dense zircon brick is mainly used in sodium - calcium glass kiln middle brick, brick arch foot, etc;Containing zirconium brick is mainly used in large glass kiln, tube furnace melting pool, regenerative chamber wall brick kiln and chemical industry, metallurgical industry solution erosion area.Appearance size, physical and chemical index of the products, service life have reached or exceed the level of similar products at home and abroad.

Our refractory plant is committed to high-end special refractory materials research, development and production, the current main products are: high purity corundum products, corundum mullite product adoprs electrocast refractories.through, mullite corundum products products, light corundum, alumina bubble products, corundum mullite product adoprs electrocast refractories.through pure zircon, zircon brick, brick, zircon brick, dense zircon brick, ordinary zirconium, zirconium corundum brick stone brick, zirconium mullite zirconium in brick, brick, zirconia hollow brick, chrome brick products, all kinds of shaped refractory material.Gongyi city god nantes kinds of refractory plant adhere to the quality strives for the survival, constantly improve the technological content of products and technology level, continuously introduce new products, pursuing with the right price, high quality products to provide customers with satisfactory and efficient service!

- Q: Application of electric high temperature regulating valve?

- Now, the definition of refractories has not only depended on the degree of refractoriness is more than 1580 degrees celsius. At present, refractory materials refer to inorganic non-metallic materials used in metallurgy, petrochemical, cement, ceramics and other production equipment lining.

- Q: How much is a thermal brick?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q: What are the advantages of refractories?

- Basic refractory material generally refers to Magnesium Oxide or Magnesium Oxide and calcium oxide as the main component of refractory materials. This kind of refractory material has higher refractoriness and strong resistance to alkaline slag.

- Q: What is the blast furnace ceramic cup called by the refractory factory?

- In fact, a kind of ceramic cup of blast furnace refractories, application in blast furnace bottom and hearth contact steel lining using a layer of non carbon refractory materials, such as Theron with corundum brick, corundum mullite and synthetic mullite bricks etc..

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: What refractory materials are adopted in each part of the blast furnace?

- The lower part of the shaft due to high temperature and dust by scouring and alkali metal vapor erosion, so the requirements for the slag resistance, alkali resistance and high temperature resistance, wear resistance of high quality clay brick, high alumina brick, carborundum brick or corundum brick. Belly temperature reaches 1400~1600, and slag, steam erosion, erosion and corrosion is strong, therefore, the silicon carbide reaction bonded silicon carbide brick.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is a kind of refractory material in refractory brick products. It is made of refractory clay or other refractory material. It belongs to the product of Si Al System

- Q: Is liquid phosphoric acid two aluminum hydrogen flammable?

- Liquid phosphoric acid two hydrogen aluminum features: easy mixing, molding, especially suitable for field construction, so liquid phosphoric acid two hydrogen aluminum is not flammable

- Q: What's the size of the fused zirconia corundum refractories for glass furnace? What are the main kilns? How much is the dosage?

- Fused zirconia corundum refractory material of glass fiber kiln quantity is little, generally used in the kiln feed arch furnace flue, where large amount of places are currently using dense zirconium Zr, dense chromium

- Q: What kind of refractory material will be used in the glass kiln?

- The content of ZrO2 in the brick is about 66%, and the bulk density is 3.7g/cm3, which has better thermal stability and anti stripping property. The use of erosion serious investment outlet area and after the parapet wall in the powder melting furnace, observation hole brick and pathway of flame space and roof parapet wall brick, brick burner. But there are also AZS burner brick with mullite brick for brick kiln and transition two side clearance brick etc..

Send your message to us

zirconium corundum refractory brick and product

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords