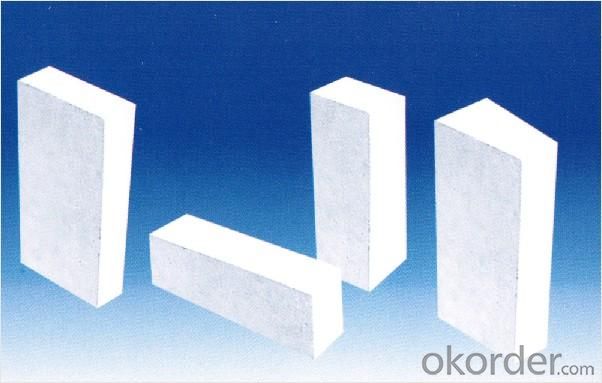

Sintered Micropore Alumina-Carbon Brick CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1 Small average pore size;

2 High thermal conductivity;

3 Low air permeability;

4 Good infiltrate and corrosion resistant.

Sintered microporous alumina-carbon bricks

1.Row material :

high quality alumina clinker ,corundum

2.Feature :

Small average pore size;

High thermal conductivity;

Low air permeability;

Good infiltrate and corrosion resistant.

3.Application: Carbon-based Refractories for iron making .

4.Packing: are packed in carton, and put carton on wooden pallet, wrapped with plastic film outside.

5.Trail order:10tons

6.Capability:200000tons per year

7.Terms of payment:L/C TT D/A D/P

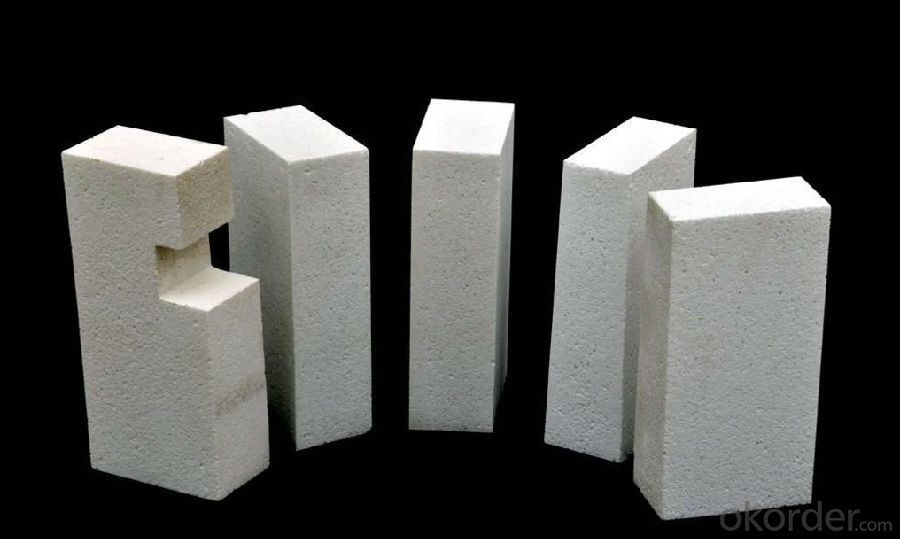

TABLE1

| NO. | ST-2-2 |

| Al2O3,% | ≥65 |

| C,% | ≥11 |

| B.D. ,g/cm3 | ≥2.85 |

| A.P. ,% | ≤16 |

| C.C.S. ,MPa | ≥70 |

Thermal conductivity /W· (m·K)-1 0-800C | ≥13 |

| Average pore size um | ≤0.5 |

| Features | Small average pore size High thermal conductivity Low air permeability Good infiltrate and corrosion resistant |

- Q: What kind of fused corundum corundum brick should be used for each part of the glass furnace?

- The compact microstructure of AZS33# zirconia corundum brick makes the bricks resistant to glass liquid corrosion, and it is difficult to produce stone or other defects in the glass kiln. It is the most widely used product in the glass furnace. It is mainly applied to the upper structure of the melting pool, the wall brick of the working pool and the paving brick, the material way, etc..

- Q: Application of electric high temperature regulating valve?

- Now, the definition of refractories has not only depended on the degree of refractoriness is more than 1580 degrees celsius. At present, refractory materials refer to inorganic non-metallic materials used in metallurgy, petrochemical, cement, ceramics and other production equipment lining.

- Q: How much is a refractory brick?

- This question is too general, refractory bricks according to the use of the environment and industry, there are a variety of materials, a variety of specifications, prices vary greatly.

- Q: What is the blast furnace ceramic cup called by the refractory factory?

- The peak of new materials in various coal, metallurgy, mines, ports, electricity, building materials and military industry, a lot of workpiece and affect production equipment due to wear, wear resistant materials although rarely cause disasters metal workpiece disaster, but the resulting economic loss is immeasurable.

- Q: What's the jade stove for?

- Corundum furnace for corundum smelting furnace, usually electric arc furnace for smelting dense corundum, corundum, white corundum, zirconia corundum, magnesia, magnesium aluminum spinel and fused refractory materials, professional design, Xi'an Xinda furnace engineering limited liability company manufacturing corundum furnace.

- Q: Which is good, glazed brick and whole cast glazed brick?

- Vitreous tile is all ceramic tile, the material is hard, strong wear resistance, smooth finish is very good, in general, looks very bright. Microcrystalline brick, corundum brick Market said, they really mean bohuazhuan. Because of its low water absorption and high strength and hardness, glazed tile has been widely used. Many hotels, shopping malls and office space are widely used glass tile.

- Q: What is the difference between corundum and high alumina?

- The main component of high purity 99 corundum brick is corundum sand,90 corundum brick is mainly composed of corundum sand and a small amount of Suzhou soil, mullite.

- Q: High temperature refractory material?

- Acid refractory with silicon oxide (SiO2) as the main ingredient, commonly used are silica brick and clay brick is siliceous. Products containing more than 93% SiO2, the use of raw materials with silica, silica and other waste brick. Acid slag erosion ability is strong, but vulnerable to the erosion of basic slag, its softening temperature is very high that is close to the refractory, the volume does not shrink after repeated burning, or even a slight swelling, but the thermal shock stability. Silica is mainly used for thermal equipment of coke oven, glass furnace, furnace and other acidic silica brick, according to the physicochemical indexes and SiO2 content can be divided into several levels, mainly brick for glass furnaces and used for coke oven two kinds of brick clay brick. With refractory clay or bauxite clinker as main raw material, containing 30% to 46% of alumina, refractory degrees 1580 to 1770 DEG C, weak acid refractory material, heat shock resistance, resistance to acid slag, wide application Pan, clay brick with refractory clay as main raw material is called ordinary clay brick, made with bauxite clinker as main raw material, the porosity in the clay brick below 17% is called low porosity clay brick. Two kinds of clay brick and according to the physicochemical indexes which were divided into several grades, the price difference between ordinary clay brick and low porosity clay brick greatly.

- Q: What's the size of the fused zirconia corundum refractories for glass furnace? What are the main kilns? How much is the dosage?

- Fused zirconia corundum brick has a strong resistance to glass liquid corrosion!It is better to fuse the furnace with fused zirconia corundum bricks.Fused zirconia corundum brick, regardless of the size of the furnace, the use of small hundreds of kilograms can be used, depending on the design of the kiln!

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

Send your message to us

Sintered Micropore Alumina-Carbon Brick CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords