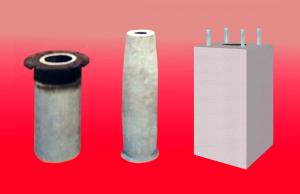

Corundum Brick - White and Sintered Corundum Refractory Brick

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our white corundum refractory sintered products imported tabular corundum brick, high purity fused corundum as main raw materials, the application of superfine powder with advanced technology, after mixing, molding, drying, in shuttle kiln high temperature burn becomes.Sintering white corundum brick with high refractoriness, good thermal shock resistance and high temperature strength, strong corrosion resistance, slag resistance and small expansion coefficient, low creep and spalling resistance, suitable for all kinds of atmosphere under the condition of high temperature furnace use;Sintering white corundum brick is widely applied in zirconia ceramics, fluorescent material, electronic ceramics, magnetic materials, ceramic powders of high temperature sintering and petrochemical industries gasifier, 2 of ammonia conversion furnace, carbon black reactor, glass industrial furnace equipment, etc.Appearance size, physical and chemical index of the products, service life have reached or exceed the level of similar products at home and abroad.

Item High Quality and High sinter Corundumbrick Mullite-corundum

Al2O3 % Purity Corundum brick ≥90 brick

SiO2 % ≤0.2 ≤8 ≤18

Fe2O3% ≤0.2 ≤0.2 ≤0.3

Density g/cm3 ≥3.2 ≥3 ≥2.8

Bulk density ≤19 ≤20 ≤20

Apparent porosity ≥100 ≥100 ≥100

CCS ≥1700 ≥1700 ≥1700

(0.2Mpa,0.6%)

Refractoriness underload Primarily used for the key parts of the industrial furnace ofsteel,electronics,petrochemical,fertilizers,non-ferrousmetals,refractory material, etc

- Q: How much is a refractory brick?

- There are many kinds of refractory bricks, you have to look at what is material, the material is not the same, the price is not the same, clay brick is the cheapest, probably hundreds of dollars a ton, and corundum brick a ton of several money, silicon carbide, silicon nitride, and more expensive. And this thing is generally on t sell, the price is by a single block after conversion.

- Q: What are the advantages of refractories?

- Aluminosilicate refractory refractory material refers to SiO2-Al2O3 as the main ingredient, according to how much the Al2O3 content can be divided into semi silica (Al2O3 15~30%), clay (Al2O3 30~48%), high alumina (Al2O3 > 48%) three.

- Q: What is the price of concrete self insulation bricks?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q: Wave tile and throwing glaze, tile which good?

- Vitreous tile is all ceramic tile, the material is hard, strong wear resistance, smooth finish is very good, in general, looks very bright. Microcrystalline brick, corundum brick Market said, they really mean bohuazhuan. Because of its low water absorption and high strength and hardness, glazed tile has been widely used. Many hotels, shopping malls and office space are widely used glass tile.

- Q: What refractory materials are used in industrial furnaces?

- Economically, it is necessary to do technical and economic analysis when selecting materials reasonably. Under the premise that the technical indexes agree with the working conditions of the furnace, the refractory materials with low quoted price should be used as much as possible, without high-grade finished products. To think about whether to make self (such as irrigation, refractory concrete) as far as possible to repair old.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- For example: 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more. 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q: Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- Do not know where the coking plant do dust treatment, processing conditions are different, the dust collector is not the same

- Q: What's the size of the fused zirconia corundum refractories for glass furnace? What are the main kilns? How much is the dosage?

- Fused zirconia corundum brick has a strong resistance to glass liquid corrosion!It is better to fuse the furnace with fused zirconia corundum bricks.Fused zirconia corundum brick, regardless of the size of the furnace, the use of small hundreds of kilograms can be used, depending on the design of the kiln!

- Q: What problems should we pay attention to in the use of fused zirconia corundum brick (fused zirconia corundum brick) in glass furnace?

- The expansion curves of fused cast AZS brick at 1000 DEG C near a crystal anomaly, its internal changes of ZrO2 crystal are reversible, with large volume change, therefore, products containing ZrO2, should not be used in the temperature of 1000 DEG C, often have sharp fluctuations in the position. When baking the kiln, the temperature can not be too large at 900~1150 degrees centigrade. Generally, the temperature can not exceed 15 degrees /h, and the temperature should be raised steadily. Some parts to prevent the cold, with other brick protection, to prevent explosion.

- Q: What can zirconium sponge do for those industries?

- Zirconium metal, also known as sponge zirconium, silver gray metal, the appearance of steel, shiny; melting point 1852 points, sub points, boiling point 4377 density 6.49. Zirconium is easy to absorb hydrogen, nitrogen and oxygen; zirconium has a strong affinity for oxygen; at 1000 DEG C oxygen dissolved in zirconium can make its volume increase significantly. Zirconium is relatively stable in the air; powder zirconium is easy to burn; fine zirconium wires can be ignited by matches; at high temperatures they can be combined directly with dissolved oxygen, nitrogen and hydrogen.

Send your message to us

Corundum Brick - White and Sintered Corundum Refractory Brick

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords