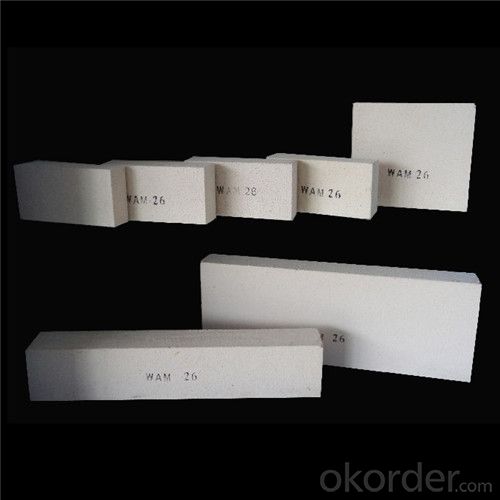

Fused Cast Alumina White Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Fused Cast Alumina White Refractory Bricks

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick, brick or as buyer's request | Material: | Castable |

| SiO2 Content (%): | 16 | Al2O3 Content (%): | 51 | MgO Content (%): | other |

| CaO Content (%): | other | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | other |

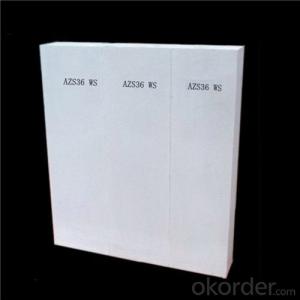

| SiC Content (%): | other | Model Number: | AZS33 white brick | Brand Name: | ZHENJIN |

| Color: | white | Model: | AZS33 | Applied: | Ceremic and Glass |

| ZrO2: | 32.0~36.0 | Certification: | ISO 9001 | Work Life: | 12 months |

| OEM: | Acceptable white brick | Sample: | Free | Origin: | Xinmi,Zhengzhou,China |

Packaging & Delivery

| Packaging Details: | wooden pallet+ carton box+plastic shrink wrap white brick |

| Delivery Detail: | 20 days after get payment |

Electro Fused Cast Brick white brick--Applied in Ceremic and Glass Kiln

Features:

1.Strong volume stability at high temperatures

2.Good thermal shock resistant

3.Wear resistance

4.Chemical corrosion resistance

Applications:

Mainly used in Glass and Ceremic Kiln.

Dominate Products Introduction:

Steel Fiber Reinforced Special Brick - Patent Product!

----For Kiln Mouth to enforce the crushing strength with good thermal shock resistance

Magnesioferrite Spinel brick------Chrome Free

Mullite-Sic Composite brick

Direct-bonded Magnesia-Chrome brick

Magnesia-Aluminum Spinel brick -----Chrome Free

Mullite-Sic Resistance brick

High Strength Alkali-Resistant brick

Antistripping High Alumina brick

Magnesia-Aluminum-Chrome Composite brick

Low-Chrome Direct-Bonded Magnesia-Chrome brick

Main Equipment Show:

2,500 tons automatic hydraulic presses

FAQ:

1. What’s the payment?

Usually T/T, others could be discussed.

2. When will you deliver the goods?

The delivery time will be determined according to the quantity of the order.

3. Do you provide samples?

Yes, samples are available.

4. How are your products’ quality?

The products will be strictly inspected before shipment, so the quality could be guaranteed.

5. Do you accept OEM?

Yes, we can do OEM.

- Q: How can the silica in zircon sand be removed during the smelting of zirconium corundum?

- From the point of view of data analysis, there is no radioactive substance in it, and it will not cause harm to the human body.It is in the production process, zirconium corundum bricks are likely to cause pollution.Fused zirconia corundum brick is also called AZS AZS English is abbreviated to AZS, is based on three chemical composition of Al2O3 - Zr02 - Sio2 phase diagram of three component system, according to the content of the order, Al2O3 A, Zr02 Z, Sio2 S, national standards for the use of this abbreviation, such as No. 33 cast brick, abbreviated as AZS, 33#, No. 36 fused zirconium corundum brick, abbreviated as AZS, 36#, No. 41 fused zirconium corundum brick, abbreviated as AZS - 41#.

- Q: What is brick power, half brick power and full brick power difference?

- All brick power up to 500 watts up and down. The internal circuit is tight and heating, the device has good adhesion, the circuit is more advanced, and the efficiency is high, so it can achieve small size and high power.

- Q: How are qualitative and qualitative refractories understood?

- Unshaped refractory products, referred to as bulk loading, are made at the place of use for the required shapes and for heat treatment, such as castable, ramming, projection, spray, refractory clay, etc..

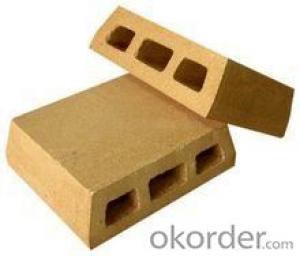

- Q: What are the forming methods of refractory materials?

- Basically there are three kinds: grouting molding, casting molding, machine forming, the three methods are applicable to different types of refractory materials, grouting molding for unshaped refractory

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- It is in the production process, zirconium corundum bricks are likely to cause pollution.

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size.

- Q: What are the main constituents of refractory bricks?

- Refractory brick composition is mainly composed of a variety of aggregate or aggregate and one or more kinds of sticky agent composed of mixed powder particles, when used, must be mixed with one or more liquids, mixing evenly, with strong liquidity. Different refractory bricks are different, such as silicon aluminum

- Q: Is the wall around the fire area using a firewall? What's the difference between a fireproof brick and a regular brick?

- A cuboid with stone walls, with mud firing, mostly red, commonly known as "red brick", there are "blue brick". The size of China's standard clay bricks is 240 x 115 * 53mm. The purpose of this size is to ensure that the length and width of the bricks are 4:2:1 (including the width of the 10mm seam). The thickness of brick to brick brick due to multiple titles, length is 240mm, so the thickness of a brick wall called "24" wall thickness of brick and a half wall called "37" wall thickness is the half brick wall is also known as the "one or two wall". Use bricks online to compare some extreme jokes.

- Q: What's the use of refractory bricks?

- Refractory material of a certain shape and size.According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: What's the weight of the refractory bricks?

- Referred to as refractory brick. Refractory made from refractory clay or other refractory material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, brick, brick and other specific type. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

Send your message to us

Fused Cast Alumina White Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords