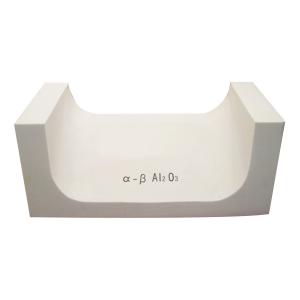

Fused Cast Brick with High Alumina Refractory Clay - Good Thermal Shock Resistance

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

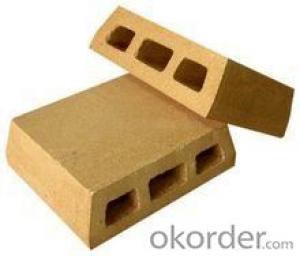

Ball mill lining brick, featured by high hardness, high density, low wear loss, good normalization, good corrosion-resistance etc. are the most ideal grinding media for glaze material, body material and various powered ores.

The high alumina lining brick can be divided into rectangular brick, trapezoidal brick and irregular brick as shape. The products has the high hardness, density, wear losses is very low, the heat degree very good, anti-corrosion, used for ball mill wear-resisting lining, widely used in ceramic, cement, paint, chemical, pharmaceutical, coating etc. and can effectively improve the grinding efficiency, reduce the grinding cost, reduce production pollution.

Application: the products are widely used as lining and grinding media of ball mill on ceremics, cements, paints, refractories, inorganic mineral powders industries, etc.

Performance index

Category | Name | 92 Series | 95 series |

Physical Property | Density | 3.60g/cm³ | 3.70g/cm³ |

Moh’s Hardness | ≥9 | ≥9 | |

water absorption | ≤0.01% | ≤0.01% | |

Appearance | Smooth, White | Smooth, milk white | |

Chemical Property | Al2O3 | ≥92% | ≥95% |

Fe2O3 | ≤0.25% | ≤0.10 |

Name | Length (mm) | Width (mm)W1 | Width (mm) W2 | Height (mm) | |

Regular size (40-90mm) | Rectangle brick | 150 | 50 | 50 | 40/50/60/70//77/90 |

Trapezoid Brick | 150 | 50 | 45 | 40/50/60/70//77/90 | |

Half-Rectangle Brick | 75 | 50 | 50 | 40/50/60/70//77/90 | |

Half-Trapezoid Brick | 75 | 50 | 45 | 40/50/60/70//77/90 | |

Flake Brick | 150 | 25 | 22.5 | 40/50/60/70//77/90 | |

Special Size Lining Brick | 80x50x55 | 55 | 50 | 50 | 80 |

110mm Lining Brick | 75 | 45 | 41 | 110 | |

110mm Lining Brick | 37.5 | 45 | 41 | 110 | |

Brick for Inlet &Outlet of ball mill | In accordance with customer’s requirements | ||||

FAQ

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

- Q: How can the silica in zircon sand be removed during the smelting of zirconium corundum?

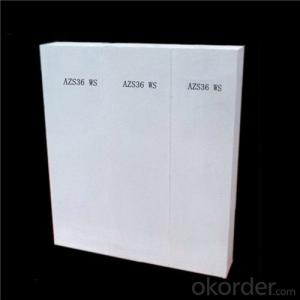

- Fused zirconia corundum brick is pure alumina and zirconia containing silica 65%, about 34% of the zircon sand in electric furnace melting after internalization into moulds cooling and the formation of the white solid, the petrographic structure by zirconium corundum and plagioclase eutectoid and glass phases, from the phase is eutectoid zirconium corundum and plagioclase phase, glass phase filling between their crystallization.

- Q: What is brick power, half brick power and full brick power difference?

- Power module. Small size, high power. General use should order additional storage energy, heat dissipation, etc.. Dimensions such as brick, so called brick power supply. Half brick power supply is half the size of all brick power supply.

- Q: How are qualitative and qualitative refractories understood?

- Unshaped refractory products, referred to as bulk loading, are made at the place of use for the required shapes and for heat treatment, such as castable, ramming, projection, spray, refractory clay, etc..

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- It is in the production process, zirconium corundum bricks are likely to cause pollution.

- Q: Just what is in the furnace material?

- Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, brick, brick and other specific type.

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Referred to as refractory brick. Refractory wood made from refractory clay or other refractory material

- Q: What are kiln bricks?

- Referred to as refractory brick. Refractory made from refractory clay or other refractory material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, brick, brick and other specific type. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: What are the specifications for bricks?

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels. Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks.

- Q: Is the wall around the fire area using a firewall? What's the difference between a fireproof brick and a regular brick?

- Fire bricks burn well!!In fact, the firewall does not necessarily have to use the so-called "fire brick", but to see the brick fire limit!240, the fire limit seems to be 4 hours, 370 I do not remember clearly, fire codes have, you see, do not think so naive!

- Q: What's the weight of the refractory bricks?

- Fireclay refractory bricks: 3.4kg-3.8kg - according to the quality of raw materials, prices ranging from 1 yuan to 2.7 yuan, high alumina refractory brick: three, high aluminum in 3.9kg or so. Ordinary T-3 firebrick weight calculation method: 230*114*65*2.2/2.1.

Send your message to us

Fused Cast Brick with High Alumina Refractory Clay - Good Thermal Shock Resistance

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords