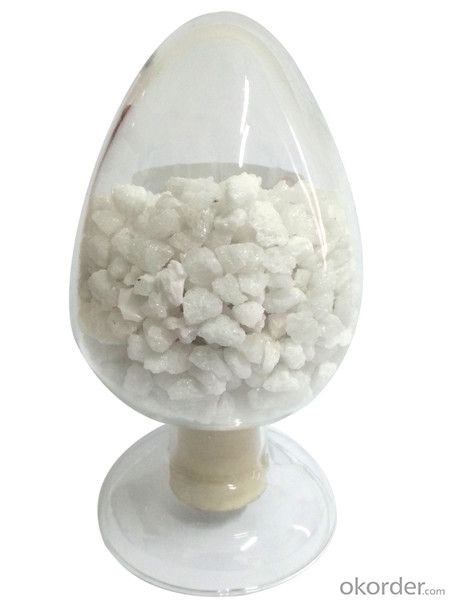

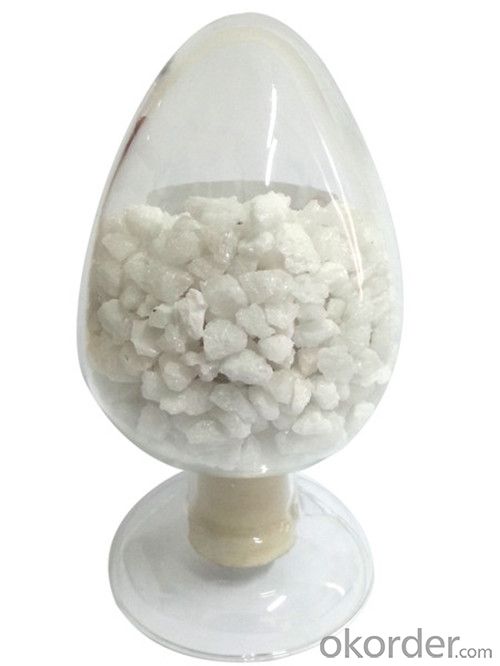

Raw Materials for Refractory - White Fused Alumina

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White Fused Alumina For Refractory Material

Specifications

White Corundum/WFA for Lapping and Polishing

1 Professional manufacturer

2 High purity

3 Good hardness and toughness

Product Description

White corundum/WFA is made from the high quality aluminum oxide powder by melting above 2,000°c in the electric arc furance and cooling.

Physical Index

| True Density | ≥3.96g/cm3 |

| Micro Hardness | HV2000-2200 |

| Mosh Hardness | 9 |

| Refractoriness | ≥1850°c |

| Melting Point | 2250°c |

Chemical Index

| Application | Specification | Chemical Composion(%) | |

| Al2O3 | Na2O | ||

| Abrasives | F12#-80# | 99.4min | 0.4max |

| 90#-150# | 99.3min | 0.4max | |

| 180#-240# | 98.2min | 0.4max | |

| 1#-63# | 99.3min | 0.4max | |

| Refractory | 180#-0 200#-0 320#-0

| 99.3min | 0.4max |

| Powder | 0-1mm 1-3mm 3-5mm 5-8mm 8-12mm | 99min | 0.4max |

Size Available

1 Abrasives F8-F1500, P12-P220, JIS240-JIS3000

2 Refractoy 0-1mm, 1-3mm, 3-5mm, 200mesh, 325mesh

3 Other specifal specification could be supplied as required

Main Applications

1 Coated and bonded abrasive tools

2 Lapping and polishing processe

3 Precision casting

4 Refractory material

- Q: How long is the fire resistant limit for ultra thin fire retardant coating?

- The fire resistant limit of ultra-thin fire retardant coating is 1.5 hours, generally fire resisting time for thin fire retardant coatings does not exceed 1.5 hours. If the time exceeds 1.5 hours, thick fire resistive coating should be uesd. There is no detailed stipulation for ultra-thin fire retardant coating, and the thickness of the inside is the fire resistance limit shall reach certain time(at least). If fire resistance limit is 2.5 hours, the thickness shall be 4.9mm. If the fire resistance limit is 2 hours, the thickness is 3.5mm. If fire resistance limit is 1.5 hour, the thickness should be 1.75mm.

- Q: What are the structural properties of refractory materials provided by the manufacturer of the refractories include?

- On the other hand, the turbulence is severe, and the side wall of the tundish is washed into the liquid steel and the service life of the lining of the tundish is reduced. In order to solve this problem, China 5%% honing develops a tundish anti turbulence pad, which is made of Al2O3>75% high alumina castable. Anti turbulence pad mounted casting ladle and tundish flow impact zone in the bottom of the flow out of the steel ladle nozzle casting hole center back in the anti turbulence pad repeatedly to consume the kinetic energy of the fluid flow, thereby reducing the steel flow speed, avoiding turbulence.

- Q: Which refractory material is better in China? Industrial furnace, mainly in non-ferrous industries, glass kiln, cement kiln business.

- Such solid nano microporous insulation material with nano inorganic refractory powder special, with a huge surface area, nano particles contact between the minimum point contact point contact thermal resistance is very large, the heat conduction effect of the material becomes very small, resulting in heat conduction coefficient of solid such nano porous insulation materials very small; nano pores formed of nanoparticles, the average size of 20 nm, and the average free path of molecular thermal motion at room temperature under static air is 60 nm, thus locking the air molecules in powder within nano pores, making the micro convection heat transfer effect between the stationary air molecules disappeared. The room temperature thermal conductivity of solid such nano microporous insulation material is lower than the static air; at high temperature, the main effect of heat transfer heat radiation, Good energy-saving insulation materials with nano microporous infrared additive special, stop at a high temperature and reflected infrared radiation, reduce the heat radiation effect to the lowest point, the radiation heat transfer coefficient of materials under high temperature is reduced to the lowest value.

- Q: What are the characteristics of clay refractory materials?

- Refractory clay refers to the refractory clay and bauxite, whose refractoriness is over 1580℃, which can be used as refractory materials. Apart from high refractoriness, they can maintain stability of volume under high temperature conditions and has resistance to slag, the sudden cold and hot, and mechanical strength, so after calcination, it can be abnormal firm.

- Q: what textures of furnace refractories are good?

- Common ceramics use ordinary clay and high alumina bricks, as well as thermal insulation bricks, calcium silicate boards and fiber cotton. The vessels fired with potter's earth are called pottery, and the vessels fired with porcelain clay are called porcelain. Ceramic is generic term of pottery, stoneware and porcelain. The objects taking the two different types of clay as the raw materials, like, potter's earth and porcelain clay, and made through the technological process of ingredients, forming, drying and roasting, ect. can be called ceramics.

- Q: What are fire resistant level standards of class A fire resistant door?

- Grade standards: class A fire resistant door is an important part of fire-fighting apparatus, and an important step in the social fireproof work. The quality and use of class A fire resistant door is closely related to the success or failure of the fireproof work.. There are steel and wood for class A fire resistant door materials. Only those whose fire endurance is no less than 1.5h can be called class A fire resistant door. In general, the class A fire resistant door internal material is perlite, and still some are vermiculite fireproof board, foam core board, MCcomposite materials, and other fireproofing materials. The thickness of class A fire resistant door is usually 50mm. In places where there is strict requirements for fireproof?performance, class A fire resistant door is often installed.

- Q: Are there any differences between insulation and refractory materials ?

- Refractory materials can resist more than 1200 degrees, some of which are not insulation materials, such as firebricks, which can directly contact with heat source, has little insulation effect. Ceramic fiber, high silica, etc. are all refractory materials which can insulate. Insulation materials with poor performance usually is lower than 800 degrees, which have large thermal resistance, and low thermal conductivity, high porosity. Thus they reduce the thermal loss. To put it simply, insulation materials store most of the heat and only let a small part of heat lose through the air, thus the heat has been isolated. Glass fiber, rock wool, flexible material for thermal insulation, etc.

- Q: How long is the fire endurance of fire resistant rolling shutter door?

- According to fire endurance, fire doors can be divided into Class A, Class B and Class C fire doors, whose fire resistance should be no less than 1.20h, 0.90h and 0.60h respectively. You can use fire resisting shutters to seperate fire?compartments in places where it is difficult to set firewalls. When using the fire resisting shutter with unexposed surface temperature rise as fire endurance conditions, its fire endurance should be no less than 3h. But when using the fire resisting shutter without unexposed surface temperature rise as fire endurance conditions, you should set independent protection of closed automatic water spray system at two sides of the shutter, and the duration of water spraying should be no less than 3.0h. I hope it's useful.

- Q: I am a refractory material manufacturer, sold products, money is always not back, anxious to die, what is the way?

- Metallurgical industry downturn. There is fierce competition in the refractory industry.

- Q: What are the additives and recipes of refractory?

- Trimeric major role played bulk water reduction effect can be considered strong trimer strong bleeding effect'm sure Hey lignin sulfonate water-reducing effect of the strong retarding superplasticizer effect in two critical recommendations with more money to buy homes are equipped who is willing to disclose ah experiments to solve the problem through Chuk Wan

Send your message to us

Raw Materials for Refractory - White Fused Alumina

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches