Fused Cast Brick MS35

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Tons m.t

- Supply Capability:

- 1000 Tons Per Mouth m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fused cast AZS firebricks-MS-35

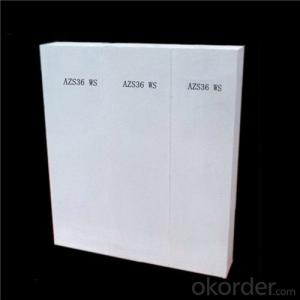

Fused cast AZS (alumina, zirconia and silica) firebricks are mainly categorized into 33#, 36# and 41# according to different zirconia's contents from 33% to 41%.

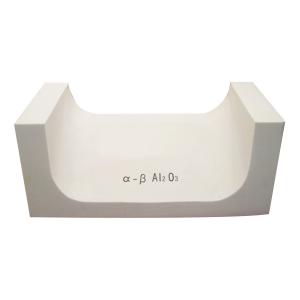

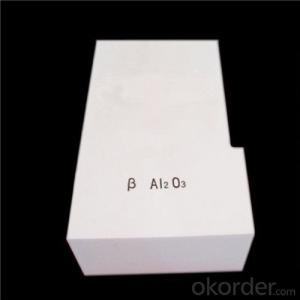

Fused cast alumina (α-β Al2O3 and β Al2O3) firebricks are composed of alpha alumina, beta alumina and small amount of glass phase.

Both AZS and alumina firebricks have shown excellent performance in glass furnace construction.

ITEM | AZS33 | AZS36 | AZS41 | α-β Al2O3 | β Al2O3 |

Al2O3≥ % | 50 | 49 | 45 | 94 | 93 |

ZrO2 ≥ % | 32.5 | 35.5 | 40.5 | _ | _ |

SiO2 ≤ % | 15.5 | 13 | 13 | 1.8 | 0.5 |

Na2O + K2O≤ % | 1.3 | 1.35 | 1.3 | 3.7 | 6 |

Bulk Density, (g/cm3) ≥ | 3.75 | 3.85 | 4 | 3.4 | 3.05 |

Apparent Porosity, ≤ % | 1.2 | 1 | 1.2 | 2 | 10 |

C.C.S., Mpa ≥ | 300 | 300 | 300 | 200 | 30 |

Exudating Temperature of Glass Phase, ℃ ≥ | 1400 | 1400 | 1410 | _ | _ |

Bubbling Tendency(1300℃×10h) (%) | 2 | 2 | 2 | 0 1000℃×10h | _ |

Anti-Corrosion Rate of Glass Liquid, 1500℃×36h (mm/24h) | 1.5 | 1.4 | 1.2 | <0.3 1350℃×10h | _ |

Feature of Fused cast AZS firebricks

High refractoriness

Excellent resistance to corrosion of molten glass

Application of Fused cast AZS firebricks

Glass furnace

Technical Data

- Q: What is brick power, half brick power and full brick power difference?

- All brick power up to 500 watts up and down. The internal circuit is tight and heating, the device has good adhesion, the circuit is more advanced, and the efficiency is high, so it can achieve small size and high power.

- Q: How are qualitative and qualitative refractories understood?

- Shaped refractory products, such as fired brick, fused brick (Rong Zhuzhuan), refractory insulation bricks, as well as experimental and industrial crucibles, utensils and other special products.

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- The fused zirconia corundum brick is mainly made of fused zirconia and corundum. ZrO2-Al2O3-SiO2 three element system fused brick, containing Al2O3:40% to 50%, ZrO2:30% to 50%, SiO2:10% to 17%.From the point of view of data analysis, there is no radioactive substance in it, and it will not cause harm to the human body.

- Q: What is the face brick

- You should be talking about refractory bricksThe refractory brick brick. Referred to as refractory material has a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick, refractory insulating bricks (Rong Zhuzhuan);

- Q: Just what is in the furnace material?

- Referred to as refractory brick. Refractory made from refractory clay or other refractory material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C.

- Q: What are kiln bricks?

- Kiln brick masonry brick kiln used brick, brick is a brick kiln.

- Q: What are the main constituents of refractory bricks?

- According to the composition of refractory bricks, they can be divided into five major categories, namely, silicon aluminum refractory bricks, basic series refractory bricks, carbon containing refractory bricks, zirconium containing refractory bricks and insulating refractory bricks. Any furnace is not made of only one kind of refractory brick, and it needs different fire bricks to match with each other. The following five categories of refractory bricks are described in detail.

- Q: Is the wall around the fire area using a firewall? What's the difference between a fireproof brick and a regular brick?

- Fire bricks burn well!!In fact, the firewall does not necessarily have to use the so-called "fire brick", but to see the brick fire limit!240, the fire limit seems to be 4 hours, 370 I do not remember clearly, fire codes have, you see, do not think so naive!

- Q: What material is good for refractory bricks?

- 1, silicon aluminum refractory bricks mainly include the following.(a) is the main varieties of acidic silica brick, refractory brick. It is mainly used for coke oven building, also used in furnaces all kinds of glass, ceramic and carbon calciner, refractory brick arches and other load-bearing parts, is also used in high temperature bearing part of hot blast stove, but should not be used in thermal equipment below 600 DEG C and the temperature fluctuation in the.(two) clay brick is a refractory brick commonly used in blast furnaces, hot blast furnaces, heating furnaces, power boilers, lime kilns, rotary kilns, ceramics and refractory bricks.(three) the mineral composition of high alumina refractory brick and high alumina refractory brick is corundum, mullite and glass phase. The raw materials are high alumina and sillimanite natural ore. They are also made of fused alumina, sintered alumina, synthetic mullite and calcined alumina in different proportions with clay. It is produced by sintering process. But the products are casting brick, brick, brick fused grain and unshaped refractory brick. High alumina refractory brick is widely used in iron and steel industry, non-ferrous metal industry and other industries.

- Q: Can the fire clay be reused?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | 2003 |

| Annual Output Value | Above US$3,330,000 |

| Main Markets | Mid East;Eastern Europe; America, Africa |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 45 people |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 21,0000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Fused Cast Brick MS35

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Tons m.t

- Supply Capability:

- 1000 Tons Per Mouth m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords