Fused Cast Brick AZS33

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 1000 Tons Per Mouth m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

General Information

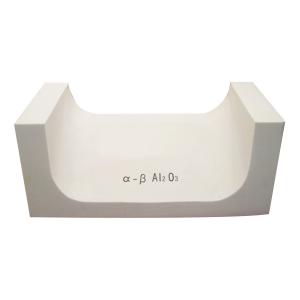

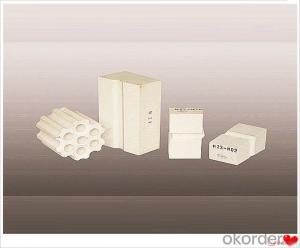

CMAX fused cast AZS (alumina, zirconia and silica) firebricks are mainly categorized into 33#, 36# and 41# according to different zirconia's contents from 33% to 41%.

Feature

High refractoriness

Excellent resistance to corrosion of molten glass

Application

Glass furnace

Technical Data

- Q: How can the silica in zircon sand be removed during the smelting of zirconium corundum?

- From the point of view of data analysis, there is no radioactive substance in it, and it will not cause harm to the human body.It is in the production process, zirconium corundum bricks are likely to cause pollution.Fused zirconia corundum brick is also called AZS AZS English is abbreviated to AZS, is based on three chemical composition of Al2O3 - Zr02 - Sio2 phase diagram of three component system, according to the content of the order, Al2O3 A, Zr02 Z, Sio2 S, national standards for the use of this abbreviation, such as No. 33 cast brick, abbreviated as AZS, 33#, No. 36 fused zirconium corundum brick, abbreviated as AZS, 36#, No. 41 fused zirconium corundum brick, abbreviated as AZS - 41#.

- Q: What is brick power, half brick power and full brick power difference?

- All brick power up to 500 watts up and down. The internal circuit is tight and heating, the device has good adhesion, the circuit is more advanced, and the efficiency is high, so it can achieve small size and high power.

- Q: What are the forming methods of refractory materials?

- Casting molding is suitable for casting brick, electric melting brick and so on. And the machine press forming is the most widely used. The common refractory brick, clay brick and other sintered brick are adopted this method.

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- Fused zirconia corundum brick is also called AZS AZS English is abbreviated to AZS, is based on three chemical composition of Al2O3 - Zr02 - Sio2 phase diagram of three component system, according to the content of the order, Al2O3 A, Zr02 Z, Sio2 S, national standards for the use of this abbreviation, such as No. 33 cast brick, abbreviated as AZS, 33#, No. 36 fused zirconium corundum brick, abbreviated as AZS, 36#, No. 41 fused zirconium corundum brick, abbreviated as AZS - 41#.

- Q: What are the categories of bricks?

- In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Referred to as refractory brick. Refractory wood made from refractory clay or other refractory material

- Q: What are kiln bricks?

- Furnace (kiln; furnace; oven) is made of refractory material used for firing products; it is a necessary facility in the formation of ceramic art. Millions of years of human porcelain history, has accumulated rich experience and made kiln style. From the primitive society to open pile burn, burn up like digging to build Steamed Buns flame round kiln, half pour flame kiln, kiln, Banpo horseshoe shaped kiln to duck's egg, indoor gas kiln, kiln kiln electric current, in the continuous improvement in the development of science and technology.

- Q: What are the specifications for bricks?

- Thecompressive node as a new type of building energy-saving wall materials, which can be used for masonry walls, but also has good thermal properties, in line with the construction of the building module, reduce the loss in the process of construction, improve work efficiency; the hole rate reached more than 35%, can reduce the weight of the wall, save the foundation engineering cost. Compared with common sintered porous brick, it has the characteristics of heat preservation, heat insulation, light weight, high strength and high construction efficiency. The product is made of shale as raw material. It is produced by high vacuum extrusion molding machine and one yard firing process

- Q: Outside wall tile (whole body smooth surface has small hole split brick) has cement pollution, with what product cleaning (cement, mortar, cleaning agent)?

- The temporary pollution in the process of tiling should be cleaned in a timely manner with a damp cloth.

- Q: What's the weight of the refractory bricks?

- Light weight brick 1 to 1.7 kilograms; heavy clay superscript brick weighs 3.75 kilograms; light 30 plates 0.79 kilograms; light 40 plates, 1.05 kilograms

Currently possess silica mining raw materials with high quality, specializing in the production and sales of high quality silica brick for glass kiln, silicon mortar, silica unshaped products. The Company have passed ISO9001 certificate enterprise.

1. Manufacturer Overview

| Location | Hunan, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | Taiwan; Germany; Italy; Turkey; France; England; Japan; Thailand; Vietnam; Idonesia; Egypt; Ukraine |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai; Shenzhen |

| Export Percentage | 20%-30% |

| No.of Employees in Trade Department | 3 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Twenty five thousand tons per year |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Fused Cast Brick AZS33

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 1000 Tons Per Mouth m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords