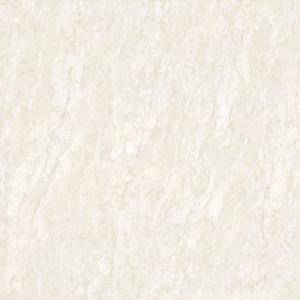

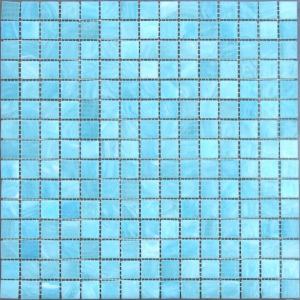

Full Polished Porcelain Tiles From China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1324.8

- Supply Capability:

- 1324800 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advantages of Full Polished Porcelain Tile:

The porcelain polished floor tiles are non-slip and easy clean and with natural veins.

The porcelain polished tiles are hardness, which are resistant to acid and alkali, waterproof, wear resistance, dirt resistacne.

Good for indoor wall and floor decorations. Elegance, promote your decorate style.

The porcelain polished tiles with high quality are ideal for creating a beautiful feel in Hotel, House, Supermarket, Shopping Mall, etc

The porcelain polished tiles ,water absorption rate :<0.1%.< span="">

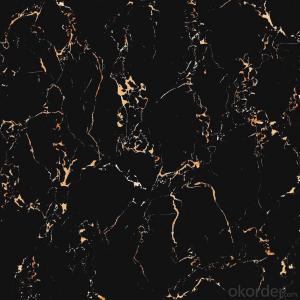

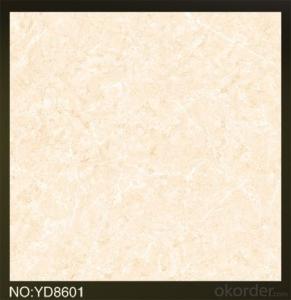

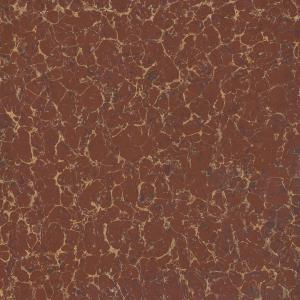

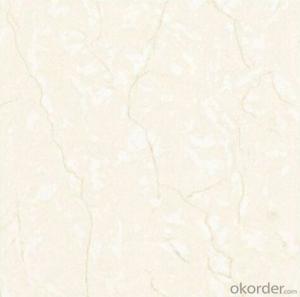

Many colors can be chosen.

The porceline tiles have 600*600,800*800 sizes, special sizes available according to request.

CE: GB/T19001-2008¬¬—ISO9001:2008

This is the best tile for hotel lobby flooring, airport, big project etc..

We have many different color and different design in this series. Please kindly check our website.

It's good for house flooring, super market, shopping mall, warehouse flooring, etc..

Our price is very competitive, and very good quality.

We have many certificates of our tiles

Main Export Markets:

Australasia

Central/South America

Eastern Europe

Mid East/Africa

North America

Western Europe

Product Pictures :

FAQ:

1. Why Us:

More than 20 years tile exporting experience, RMB 200 million sales every year.

More than 20 years tile factory running-well management experience.

Excellent quality and Competitive price, OEM is available.

Widely professional exporting experience all over the world.

2. What is the trade terms:

Payment: T/T 50% in advance, balance against copy of T/T, L/C etc.

3. What is the delivery time

15- 20 after deposit paid

4. Can you provide the samples to check?

We can provide the clients free samples.

- Q: the bathroom at work has lenulium sheet. I slip when it rains, b cos it is wet. I want to replace home carpeting with tiles or vynal. which one is less slippery? thanks

- They are equally slick. If deciding on tiles, I recommend some with texture. It helps. I have torn my ACL and went through the tile vs. vinyl. textured tile also hides any scratches etc.

- Q: I am installing commercial tile and I have no idea what tool is used to cut this kind of tile, it easily breaks if its bent too hard. I need to cut curved areas on this tile and I have no idea what too to use. Please help! ;)

- If you are talking about vinyl tile you can use an hair drier to soften the tile so you can cut it without it crumbling. Use a curved tin snip or a utility knife to cut after softening. You should be able to lay it flat on the floor, soften it, scribe it with the utility knife, and then snap it. If you are talking about ceramic tile you should use a tile saw. You can rent one for about $60/day. You can buy one in Home Depot or Lowe's for about $90.

- Q: I have a tile floor in my kitchen, and I have tiles in both of my bathrooms, floors and shower walls. Whats is the best way to clean these with out removing the grout?

- Kaboom grout cleaner. Not tub and tile. There is to different ones. They both are very good. If you can find the Kaboom grout cleaner It will do all of it. Other wise use hot water and Just a cap full of the tub and tile cleaner from kaboom ,

- Q: Tile loss rate

- Tile loss is usually calculated at 5% Alien by more than 8%

- Q: i was wondering if it would be a good idea to use patio tiles or something similar as flooring for a bearded dragon tank, im thinking of getting one but there are a lot of different opinions on what to put on the floor for them, i thought of patio tiles, as theyre originally from rocky areas and they cant caause impation, if it isnt a good idea please offer alternitivesthnx:)x

- Hi there you have to be careful using these becauze if it getsx cold, he can prolapse and this can be expensive to fix. if it can be fixed. i prefer paper for babies then gradulate up to the calci sands when older.

- Q: OK here is my problem. I want to switch my bath tub to an all-tile shower and wonder how to do it. So far the tile were set onto a cement board that was itself put on top of the drywall. I am wondering if this is a common thing. From all my research, it looks like tile should be on the cement board, but there is no use for extra drywall behind it. It actually makes things tougher because you need some sort of corner tile instead of normal bullnose since the cement board and the rest of the wall are not at the same level.My second question is: is there an order to do all this i.e. should I make the shower pan (sort of rubber sheet filled with cement), before or after I install the cement board on the wall. Is there a specific angle used for the drain?Thanks in advance for all your tips.

- take off all tile and wallboard down to the studs.move all plumbing,use a pvc liner which bolts to the drain flange.when nailing the liner to the studs run the liner about a foot up the wall.no fastners 9in or lower or it will leak.put up your concrete board,remember no fastners 9in or lower concrete will hold the bottom.form a curb using 2x6s run the liner in the middle of the form. use a 2x6 braced against the back wall inside the shower to hold the form inside the shower. fill with concrete on both sides.i use quickcrete sand topping mix.let the curb dry for 24 hrs.pull the form.now pour concrete inside the curb. your pan should have a pitch of 1/4 in.for every foot from the drain.let dry again for 24 hrs.do not use wall mastic as adhesive for the tile, use mortar.i also use hydroguard 1 from dal-tile in the corners and seams.you can brush it on.now your ready to tile.if you dont have any bullnose ,you can use a metal trim. i use dal-tile #a100.get a mosiac tile for the floor so it will wrap the pitch of the floor.use a sanded grout on the floor.you can butt the tile joints on the wall but if you do, use a nonsanded grout.silicone all corners.putting in a custom shower is one of the hardest thing you can do in your home,

- Q: We currently have carpet throughout our house, but due to having dogs, we hate the carpet. While hardwood or laminate seems the logical choice, tile would hold up much better to their toe nails. My concern is how having tile throughout the entire house (even in the living room, computer room, bedrooms, etc) would look. I know it is done sometimes, but I just can't picture it in my mind. How do you feel about it? Would the tile (it would be very neutral in color) be okay through the entire house or should we go with laminate deal with the scratches when/if they happen?

- We have Pergo flooring and it doesn't show dog scratches. I think tile flooring throughout an entire house is cold and echoey! But if you go with the tile, you could always get rugs.

- Q: i want to tile my house, i also want to pay less than a dollar per square foot for the materials. on top of that i want 16 tile... i know these deal exhist but i dont know where to look... please help

- Home Depot or Lowes..but remember if you pay 69 a sqaure foot,,,,which is cheap........it is seconds,some will be uneven,but it is a good price

- Q: Does floor tile give a lot of heat? I want to get a tile substrate for my leopard gecko, but I don‘t know if it will get warm enough for him. I have an under tank heater, so if I put the tile in will the heat from the under tank heater block or go through the tile?

- Yes, tiles are great. The tile will retain heat, so that's even better. Leo's are found on hard clay in the wild so tiles are the best replica.

Send your message to us

Full Polished Porcelain Tiles From China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1324.8

- Supply Capability:

- 1324800 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches