FRP Pultrusion Profiles - FRP Square Tube for FRP Ladder and Guardrail

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

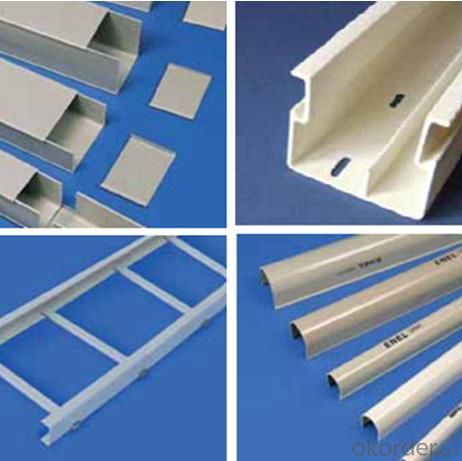

FRP guardrail are made by assembling of FRP pultrusion profiles. They divided into four types, they are standard square type, economic type, standard round type and heighten type, the type of profile and the installation distance, height, position and quantity can be changed per the customer’s requirement, the color also could be selected according the client’s demand.

Pultrusion process is a machanized process for FRP composites,involves pulling a collection of fibres in the form of roving,mat or fabric through a resin bath and then through a heated die to cure the resin and then take shape of profiles.

FRP grating platform, walkways, ladder,guardrail,plant of cooing tower,sporting profiles,tool handls and other load structures.

FEATURES

a. anti-corrosion, anti-rust

b. light weight and high strength

c. vivid color

d. anti-ageing

e. good property of non-magnetism

f. safety

SPECIFICATION

Standard Square type

Handrail | Rung | Post | Kick plate |

Square tube 50*50*4 | Square tube 50*50*4 | Square tube 50*50*4 | Flat panel 101.6*3 |

Economic type

Handrail | Rung | Post | Kick plate |

Channel 57*60*3 | Square tube 38*38*4 | Square tube 50*50*4 | Flat panel 101.6*3 |

Standard round type

Handrail | Rung | Post | Kick plate |

Round tube φ50*4 | Round tube φ50*4 | Round tube φ50*4 | Flat panel 101.6*3 |

Heighten type

Handrail | Rung | Post | Kick plate |

Channel 57*60*3 | Round tube 32*3 | Square tube 50*50*4 | Flat panel 101.6*3 |

PICTURES

- Q: Can FRP pultrusion profiles be customized according to specific requirements?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be customized according to specific requirements. Pultrusion is a manufacturing process that involves pulling continuous fibers through a liquid resin bath, then through a heated die to cure the resin and form the desired shape. This process allows for great flexibility in design and customization. The customization options for FRP pultrusion profiles include various dimensions, shapes, colors, and surface finishes. The dimensions can be tailored to meet specific length, width, and thickness requirements. The shapes can range from basic geometries like rectangular or round profiles to more complex designs with custom cross-sections. In terms of color, FRP pultrusion profiles can be pigmented during the manufacturing process to achieve the desired color or can be painted or coated afterwards. This allows for matching specific color requirements or ensuring compatibility with existing structures or products. Furthermore, surface finishes can be customized to achieve desired properties such as increased slip resistance, UV resistance, or fire resistance. Surface treatments like sanding, coating, or adding special additives can be applied to meet specific performance requirements. Overall, FRP pultrusion profiles offer a high level of customization to meet specific project or application needs. They are versatile, lightweight, corrosion-resistant, and have excellent strength-to-weight ratios, making them suitable for various industries such as construction, transportation, infrastructure, and aerospace.

- Q: The difference between polyurethane pultruded profiles and glass reinforced plastic profiles

- Compared with other materials, pultrusion with polyurethane can produce a variety of benefits. The utility model can improve the content of the glass fiber in the product and greatly improve the strength of the product. For example, pultruded window frames made of glass fiber and polyurethane resin, the strength of the resulting window frames is 8 times higher than that of the PVC window frames, and the conductivity is 40 times lower than that of aluminum. Therefore, the insulation performance is much better.

- Q: Can FRP pultrusion profiles be used in the construction of train or subway platforms?

- Yes, FRP pultrusion profiles can be used in the construction of train or subway platforms. FRP (Fiber Reinforced Polymer) offers excellent strength, durability, and corrosion resistance, making it suitable for high-traffic areas like train or subway platforms. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, making them a versatile choice for platform construction.

- Q: Can FRP pultrusion profiles be used in telecommunications applications?

- Telecommunications applications can utilize FRP pultrusion profiles, which offer a range of advantages that render them suitable for such infrastructure. To begin with, these profiles possess the desirable combination of being lightweight and strong, making them an excellent choice for supporting antennas, cable trays, and equipment racks. Their high strength-to-weight ratio enables easier installation and transportation while providing the necessary structural support. Moreover, FRP pultrusion profiles display corrosion resistance, a crucial characteristic for telecommunications applications. Given the exposure of telecommunications infrastructure to harsh environments like moisture, chemicals, and extreme temperatures, FRP's non-corrosive properties guarantee long-term durability and reliability, distinguishing it from traditional materials such as steel or wood. Additionally, FRP pultrusion profiles offer electrical insulation properties, which are vital in telecommunications applications. By not conducting electricity, they ensure safety in areas where electrical equipment is present. This feature prevents electrical interference and preserves the integrity of the telecommunications system. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, as they can be manufactured in various shapes and sizes. This flexibility allows for the efficient design of telecommunications infrastructure, making FRP pultrusion profiles suitable for a wide range of applications within the industry. In conclusion, FRP pultrusion profiles prove to be well-suited for telecommunications applications due to their lightweight yet strong nature, corrosion resistance, electrical insulation properties, and customization possibilities. These attributes guarantee their reliability in supporting and protecting telecommunications infrastructure.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of boat hulls?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are suitable for the manufacturing of boat hulls. FRP pultrusion profiles offer several advantages that make them ideal for boat hull construction. Firstly, FRP pultrusion profiles are lightweight yet extremely strong and durable. This makes them ideal for boat hulls as the lightweight construction allows for improved fuel efficiency and increased speed. Additionally, the high strength-to-weight ratio ensures that the boat can withstand the stresses and strains of the water without compromising its structural integrity. Secondly, FRP pultrusion profiles are highly corrosion-resistant. This is a crucial characteristic for boat hulls as they are constantly exposed to water, salt, and other corrosive elements. The corrosion resistance of FRP pultrusion profiles ensures that the boat hull remains intact and retains its performance over time, reducing the need for frequent maintenance and repairs. Furthermore, FRP pultrusion profiles offer design flexibility. They can be easily molded into various shapes and sizes, allowing for customization and optimization of boat hull designs. This flexibility enables boat manufacturers to create hulls that are not only functional but also aesthetically appealing. In addition to their strength, durability, corrosion resistance, and design flexibility, FRP pultrusion profiles also offer excellent electrical and thermal insulation properties. This is particularly important for boat hulls as it helps to prevent electrical currents and heat from passing through the hull, ensuring the safety and comfort of passengers and crew. Overall, FRP pultrusion profiles provide an excellent solution for the manufacturing of boat hulls. Their lightweight, strong, and corrosion-resistant properties, along with design flexibility and insulation capabilities, make them an ideal choice for boat manufacturers looking to create high-performance and long-lasting vessels.

- Q: Are FRP pultrusion profiles resistant to fire?

- Yes, FRP pultrusion profiles are inherently fire resistant. The combination of the polymer matrix and the reinforcing fibers used in the pultrusion process provides excellent fire resistance properties, making them a suitable choice for applications where fire safety is a concern.

- Q: Are FRP pultrusion profiles non-conductive?

- Yes, FRP pultrusion profiles are non-conductive.

- Q: Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Indeed, FRP pultrusion profiles have the capability to be utilized in wastewater treatment facilities. These profiles possess numerous benefits, including a high strength-to-weight ratio, resistance to corrosion, and durability, all of which make them highly suitable for the challenging conditions found in such facilities. In wastewater treatment facilities, there exists a wide range of applications where FRP pultrusion profiles can be effectively employed. These applications encompass walkways, handrails, ladders, grating, and structural supports, among others. The corrosion resistance of FRP makes it particularly well-suited for deployment in areas that are exposed to moisture and the chemicals present in wastewater. Furthermore, the lightweight nature of FRP profiles simplifies the installation process and reduces the burden placed on supporting structures. The durability of FRP pultrusion profiles guarantees long-term performance, even in aggressive environments. They exhibit a remarkable resistance to chemical attacks, UV radiation, and bacterial growth, rendering them highly appropriate for wastewater treatment applications. Additionally, FRP profiles can be tailored to meet specific load requirements and can be easily fabricated to accommodate various shapes and sizes. Furthermore, FRP pultrusion profiles possess outstanding electrical insulation properties, which can prove advantageous in wastewater treatment facilities where electrical safety is of utmost concern. To summarize, FRP pultrusion profiles can be effectively employed in wastewater treatment facilities due to their corrosion resistance, durability, lightweight nature, and versatility in terms of design and fabrication. These profiles provide long-lasting solutions for a variety of applications within these facilities, ensuring operational efficiency and minimizing maintenance needs.

- Q: Can FRP pultrusion profiles be used in the construction of offshore platforms?

- FRP pultrusion profiles have the capability to be utilized in the construction of offshore platforms. These profiles possess a range of beneficial characteristics that render them appropriate for offshore applications. To begin with, FRP pultrusion profiles exhibit a combination of lightness and strength, which is vital for withstanding the harsh environmental conditions encountered by offshore platforms, such as strong winds, waves, and corrosive saltwater. The high strength-to-weight ratio of FRP makes it an optimal choice for reducing overall weight while preserving structural integrity. Moreover, FRP is exceptionally resistant to corrosion, unlike conventional construction materials like steel. This is particularly crucial in offshore environments where metal structures can rapidly corrode due to exposure to saltwater. FRP pultrusion profiles remain unaffected by rust or corrosion, resulting in extended service life and diminished maintenance costs. Additionally, FRP pultrusion profiles possess the capability to be designed and manufactured with exceptional fire resistance properties. This is of utmost importance for offshore platforms, as fire incidents can lead to catastrophic consequences. FRP materials can be engineered to satisfy specific fire safety standards, providing an additional layer of protection. Furthermore, FRP pultrusion profiles offer design flexibility, as they can be easily tailored to meet individual project requirements. This allows for the creation of intricate shapes and sizes, facilitating efficient construction and installation of offshore platforms. In conclusion, the lightweight, corrosion-resistant, fire-resistant, and customizable nature of FRP pultrusion profiles deems them an appropriate choice for constructing offshore platforms. They offer numerous advantages over traditional materials, contributing to enhanced safety, durability, and cost-effectiveness in offshore construction projects.

- Q: Do FRP pultrusion profiles require any special tools for installation?

- Yes, FRP pultrusion profiles do require special tools for installation. These tools typically include saws for cutting the profiles to size, drills for creating holes, and adhesive application tools for bonding the profiles to the substrate. Additionally, specialized fasteners and brackets may be needed to secure the profiles in place. It is important to use these tools correctly to ensure a proper and secure installation of FRP pultrusion profiles.

Send your message to us

FRP Pultrusion Profiles - FRP Square Tube for FRP Ladder and Guardrail

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords