FRP Roofing Panel - Corrugated GRP Plastic Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

The FRP roof tile using in factories, warehouses, car parks, agricultural, freezer, food processing plants, restaurants, laboratory, heat-insulation sheds, weather corridors, lighting sheds, sun sheds, greenhouses, etc.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATION

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

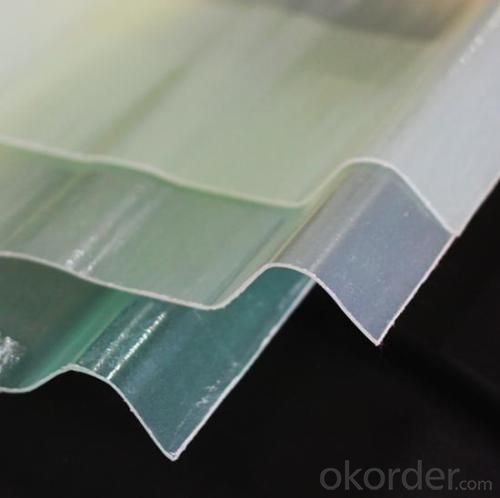

PICTURES

- Q: Do FRP roofing panels require any special maintenance?

- FRP (Fiberglass Reinforced Plastic) roofing panels generally do not require any special maintenance. However, like any other roofing material, regular cleaning and inspections are necessary to ensure longevity and optimal performance. Cleaning FRP roofing panels can be done with water and a mild detergent, or a non-abrasive cleaner. Avoid using harsh chemicals or abrasive materials that could damage the surface. It is advisable to check with the manufacturer for specific cleaning instructions as different coatings or finishes may require different cleaning methods. Regular inspections are essential to identify any signs of damage or wear. Check for cracks, loose fasteners, or any areas where the panels may have become dislodged. Repair or replace any damaged panels promptly to prevent further issues or water leakage. Additionally, it is important to keep gutters and drains clear of debris to allow proper drainage and prevent water pooling on the roof. This will help maintain the integrity of the FRP roofing panels and reduce the risk of leaks or structural damage. Overall, while FRP roofing panels are relatively low-maintenance, it is crucial to follow regular cleaning and inspection routines to ensure their longevity and optimal performance.

- Q: Can FRP roofing panels be used for covered walkways in universities or college campuses?

- Covered walkways in universities or college campuses can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. The popularity of FRP panels for such purposes stems from their durability, versatility, and cost-effectiveness. These panels possess a lightweight yet sturdy nature, enabling the creation of long-span structures like covered walkways. Moreover, FRP panels demonstrate excellent resistance to harsh weather conditions, safeguarding against rain, snow, and UV radiation, all of which are particularly crucial for outdoor structures. Furthermore, universities and college campuses can personalize the walkways by selecting from a wide range of colors and designs available for FRP panels. In summary, when it comes to constructing covered walkways in educational institutions, FRP roofing panels serve as a dependable and pragmatic choice.

- Q: What is the expected lifespan of FRP roofing panels?

- The expected lifespan of FRP roofing panels can vary depending on various factors such as the quality of the panels, the installation process, and the environmental conditions in which they are exposed to. However, on average, FRP roofing panels can have a lifespan of around 20 to 30 years. FRP, also known as fiberglass reinforced plastic, is a durable and lightweight material that is resistant to corrosion, UV radiation, and extreme weather conditions. This makes it a popular choice for roofing applications, especially in areas with harsh climates. Proper installation and regular maintenance are crucial for maximizing the lifespan of FRP roofing panels. Regular inspections and cleaning can help prevent the accumulation of debris, which can deteriorate the panels over time. Additionally, applying a protective coating or sealant can further enhance the longevity of the panels by providing an extra layer of protection against wear and tear. It is important to note that the lifespan of FRP roofing panels can also be influenced by the specific brand or manufacturer. Some manufacturers may offer panels with extended warranties, indicating their confidence in the longevity of their products. Therefore, it is advisable to consult with a reputable supplier or manufacturer to determine the expected lifespan of specific FRP roofing panels before making a purchase.

- Q: Are FRP roofing panels resistant to harsh cleaning agents?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to harsh cleaning agents. The chemical composition of FRP panels allows them to withstand exposure to various cleaning agents without significant damage or degradation. However, it is always recommended to consult the manufacturer's guidelines or perform a spot test before using any specific cleaning agent on FRP roofing panels to ensure compatibility and avoid any potential issues.

- Q: Can FRP roofing panels be installed on historical or listed buildings?

- FRP roofing panels can be installed on historical or listed buildings, but it is important to carefully consider certain factors before proceeding with the installation. Firstly, it is essential to understand the specific regulations and guidelines of the governing body responsible for the preservation of historical or listed buildings in the particular region. These regulations vary and may have strict requirements regarding the preservation of the building's original look and materials. In some cases, the use of FRP roofing panels may be prohibited, especially if the building's historical value lies in the original roofing material or design. The governing body may require the use of traditional roofing materials to maintain the authenticity of the building. However, if the regulations allow for the use of modern materials like FRP roofing panels, it is crucial to ensure that the panels are designed and installed in a manner that does not compromise the historical integrity of the building. This may involve careful color matching, texture replication, or architectural detailing to blend seamlessly with the existing structure. It is also advisable to consult with professionals experienced in historical building preservation, such as architects, engineers, or preservation specialists. They can provide valuable insights and guidance on the compatibility of FRP roofing panels with the building's historical significance. Ultimately, the decision to install FRP roofing panels on historical or listed buildings should be made after a thorough analysis of the building's historical value, local regulations, and consultation with experts in the field.

- Q: Can FRP roofing panels be used for patio covers or pergolas?

- FRP roofing panels are suitable for patio covers or pergolas. They possess qualities such as being lightweight, durable, and resistant to UV rays, which make them an excellent choice for outdoor structures like patio covers and pergolas. These panels offer exceptional protection against rain, snow, and harmful sun rays. Furthermore, installing and maintaining FRP panels is hassle-free, making them a favored option for DIY projects. Whether you desire to construct a shaded outdoor living area or an ornamental structure, FRP roofing panels can serve as an ideal choice for your patio cover or pergola.

- Q: Can FRP roofing panels be installed on wooden structures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on wooden structures. FRP panels are lightweight and can be easily installed on various types of substrates, including wood. The key consideration when installing FRP panels on wooden structures is ensuring a proper installation process. This includes ensuring that the wooden structure is in good condition, free from any rot or damage, and providing adequate support for the panels. It is also important to follow the manufacturer's guidelines and recommendations for installation to ensure a secure and long-lasting installation. Overall, with proper installation techniques, FRP roofing panels can be successfully installed on wooden structures, providing a durable and weather-resistant roofing solution.

- Q: Can FRP roofing panels be used for outdoor kitchens?

- Yes, FRP roofing panels can be used for outdoor kitchens. They are durable, lightweight, and resistant to weather elements, making them a suitable choice for outdoor applications. Additionally, FRP panels are easy to clean, provide good insulation, and can enhance the aesthetics of the outdoor kitchen.

- Q: Can FRP roofing panels be used for pergolas or outdoor seating areas?

- Certainly, pergolas or outdoor seating areas can make good use of FRP (Fiberglass Reinforced Plastic) roofing panels. Renowned for their durability, lightweight composition, and ability to withstand diverse weather conditions, FRP panels emerge as an exceptional selection for outdoor structures. They provide essential protection against the sun, rain, and other elements, thus ensuring the creation of a comfortable and enjoyable space. Moreover, FRP panels come in a variety of colors and styles, allowing for customization that aligns with the desired aesthetic of your pergola or seating area. Ultimately, FRP roofing panels prove themselves to be a dependable and pragmatic choice for elevating the functionality and visual appeal of outdoor spaces.

- Q: Can FRP roofing panels be painted?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be painted. However, it is important to follow specific guidelines to ensure proper adhesion and longevity of the paint. Firstly, the FRP panels should be thoroughly cleaned and free of any dust, dirt, or debris. It is recommended to use a mild detergent and water solution to clean the surface. Once the panels are clean and dry, a primer designed for use on FRP should be applied. This helps the paint adhere to the surface and provides a better finish. After the primer has dried, a high-quality exterior-grade paint can be applied using a brush, roller, or spray gun. It is essential to choose a paint that is compatible with fiberglass and suitable for outdoor use. It is also advisable to apply multiple thin coats of paint rather than a thick coat to achieve a more even and durable finish. Overall, with proper preparation and the right paint products, FRP roofing panels can be successfully painted to enhance their appearance and protect them from the elements.

Send your message to us

FRP Roofing Panel - Corrugated GRP Plastic Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords