FRP Pultrusion Profiles - FRP Gratings, Fiberglass Solid Grilles & Water-Resistant Steel Grating in Various Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

- Aging Resistance

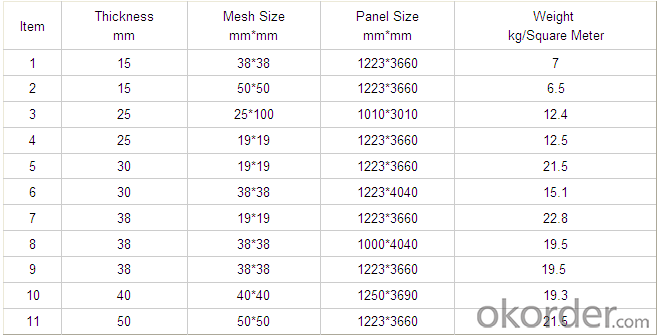

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

- long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

- All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

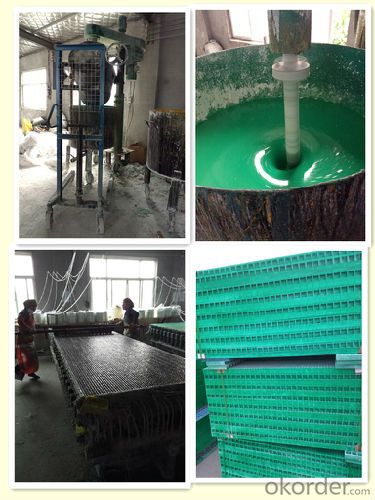

PROCESS

FACTORY

- Q: Are FRP pultrusion profiles resistant to jet fuel?

- Yes, FRP pultrusion profiles are generally resistant to jet fuel.

- Q: How do FRP pultrusion profiles perform in high-temperature applications?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their excellent performance in high-temperature applications. The combination of the reinforcement fibers and the polymer matrix used in the pultrusion process results in a material that exhibits superior thermal stability and resistance. One of the key advantages of FRP pultrusion profiles in high-temperature applications is their ability to withstand elevated temperatures without losing structural integrity. Unlike traditional materials like steel or aluminum, which may experience deformation or failure under high temperatures, FRP pultrusion profiles maintain their shape and performance. The specific performance of FRP pultrusion profiles in high-temperature applications depends on the choice of reinforcement fibers and the polymer matrix used. Different fibers, such as glass, carbon, or aramid, have varying thermal resistance properties. By selecting the appropriate fiber type and resin system, manufacturers can tailor the FRP pultrusion profiles to withstand specific temperature ranges. FRP pultrusion profiles are also known for their low thermal conductivity, which means they do not conduct heat as efficiently as metals. This property makes them suitable for insulation applications, as they can help minimize heat transfer and maintain a stable temperature environment. Moreover, FRP pultrusion profiles are resistant to corrosion, which is particularly advantageous in high-temperature environments where metals can corrode more rapidly. Their corrosion resistance ensures long-term durability and reduces maintenance requirements. In summary, FRP pultrusion profiles excel in high-temperature applications due to their structural integrity, thermal stability, low thermal conductivity, and corrosion resistance. Manufacturers can customize the material composition to meet specific temperature requirements, making FRP pultrusion profiles a reliable choice for a range of industries, including aerospace, automotive, chemical processing, and oil and gas.

- Q: Can FRP profiles replace carbon steel profiles?

- I am a man of glass fiber reinforced material. Honestly, "I can't do it."". Can be used in buildings, such as insulation, corrosion protection, aging resistance, flame retardant, etc.,

- Q: Can FRP pultrusion profiles be used in the water and wastewater treatment industry?

- FRP pultrusion profiles have the capability to be utilized in the water and wastewater treatment sector. These profiles possess exceptional mechanical properties, durability, and corrosion resistance, making them suitable for a wide range of applications in this industry. The resistance to corrosion is one of the primary benefits of FRP pultrusion profiles. Water and wastewater treatment facilities often face corrosive environments, high humidity, and aggressive chemicals. Unlike traditional materials such as wood or steel, FRP pultrusion profiles are specifically engineered to endure these harsh conditions without corroding. This ensures long-term performance and reduces the need for frequent maintenance or replacement, ultimately decreasing costs. Moreover, FRP pultrusion profiles offer an excellent strength-to-weight ratio, making them perfect for structural purposes in water and wastewater treatment facilities. These profiles can be utilized as walkways, handrails, grating, ladders, and other structural components. Their lightweight nature allows for easy installation and minimizes the burden on supporting structures. Additionally, FRP pultrusion profiles are non-conductive, providing an added safety advantage in water and wastewater treatment facilities. This is especially crucial when working with electrical equipment or in areas close to water sources, as it reduces the risk of electrical hazards. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, including different shapes, sizes, and colors. This flexibility allows for greater design freedom, ensuring that the profiles can be tailored to fit the unique needs of water and wastewater treatment projects. In summary, the utilization of FRP pultrusion profiles in the water and wastewater treatment industry offers numerous advantages, including corrosion resistance, high strength, lightweight properties, non-conductivity, and design flexibility. These qualities make FRP profiles a dependable and cost-effective choice for various applications in this industry.

- Q: Are FRP pultrusion profiles resistant to chemical spills or leaks?

- FRP pultrusion profiles are known for their high resistance to chemical spills or leaks, making them an excellent choice for construction projects. One of the main benefits of using FRP as a building material is its exceptional chemical resistance. These profiles are made by impregnating continuous fibers with a thermosetting resin, resulting in a durable composite material. The selection of the resin used in FRP pultrusion profiles depends on the specific chemical environment they will be exposed to. This allows for customization and optimization of the composite's ability to withstand different chemicals. Additionally, the fibers used in FRP are typically chemically inert, further enhancing the profiles' resistance to chemical spills or leaks. FRP pultrusion profiles have proven to be highly resistant to a wide range of chemicals, including acids, alkalis, solvents, and corrosive substances. They are commonly used in industries such as chemical processing, water and wastewater treatment, oil and gas, and marine applications, where exposure to aggressive chemicals is common. Apart from their chemical resistance, FRP pultrusion profiles offer several other advantages. They are lightweight yet strong and stiff, making them ideal for applications that require structural integrity. They are also non-conductive, non-magnetic, and have excellent electrical insulation properties. Overall, FRP pultrusion profiles are a reliable option for environments where chemical spills or leaks are a concern. They provide robust resistance to a wide variety of chemicals, ensuring long-lasting performance and minimal maintenance requirements.

- Q: Can FRP pultrusion profiles be used in telecommunications towers?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in telecommunications towers. FRP materials offer several advantages for such applications, including high strength-to-weight ratio, corrosion resistance, and electrical non-conductivity. These properties make FRP pultrusion profiles suitable for use in telecommunications towers, providing structural support while offering durability and longevity.

- Q: What are the environmental benefits of using FRP pultrusion profiles?

- FRP pultrusion profiles offer several environmental benefits. Firstly, they are lightweight, which reduces the energy required for transportation and installation compared to traditional materials like steel or concrete. This leads to reduced carbon emissions during the entire lifecycle of the product. Additionally, FRP is highly durable and resistant to corrosion, which means that it has a longer lifespan and requires less maintenance and replacement. This reduces waste generation and conserves resources. Moreover, FRP pultrusion profiles are non-toxic and do not release harmful chemicals or pollutants into the environment. Overall, their use contributes to sustainable practices and helps in minimizing the environmental impact of various industries.

- Q: Can FRP pultrusion profiles be used in the telecommunications industry?

- Indeed, the telecommunications industry can use FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles have numerous advantages that make them appropriate for telecommunications applications. Firstly, FRP pultrusion profiles are both lightweight and immensely strong, making them perfect for telecommunications infrastructure. They can be utilized in the design and construction of structures such as antenna mounts, support poles, cable trays, and enclosures. The lightweight nature of FRP profiles simplifies installation and maintenance, reducing the overall cost and effort involved in establishing and upkeeping telecommunications systems. Secondly, FRP pultrusion profiles possess exceptional corrosion resistance properties. This is especially crucial in the telecommunications industry, as infrastructure components are frequently exposed to harsh weather conditions and environmental factors. Unlike traditional materials like steel or aluminum, FRP profiles do not rust or corrode, guaranteeing their durability and dependability in telecommunications applications. Moreover, FRP pultrusion profiles provide electrical insulation properties, which are essential in the telecommunications industry. These profiles do not conduct electricity, making them suitable for applications requiring electrical grounding or isolation. This characteristic ensures the safety of telecommunications equipment and personnel. Furthermore, FRP pultrusion profiles can be tailored to meet specific project requirements. They can be engineered with specific dimensions, shapes, and load-bearing capacities as needed. This flexibility allows for the design and fabrication of telecommunications infrastructure that meets the unique demands of each project. In conclusion, FRP pultrusion profiles are well-suited for telecommunications applications due to their lightweight, high strength, corrosion resistance, electrical insulation properties, and customization options. These profiles offer a reliable and cost-effective solution for various applications within the telecommunications sector.

- Q: Can FRP pultrusion profiles be used in the automotive manufacturing industry?

- Yes, FRP pultrusion profiles can be used in the automotive manufacturing industry. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. These profiles can be used in various automotive applications including body panels, structural components, and interior trim.

- Q: Are FRP pultrusion profiles resistant to nitric acid?

- FRP pultrusion profiles exhibit a general resistance to nitric acid. Nitric acid, being a potent oxidizing agent, has the ability to corrode various materials, including metals. However, the construction of FRP pultrusion profiles involves the use of composite materials that are specifically engineered to withstand the effects of corrosive substances, including nitric acid. The resilience of FRP pultrusion profiles against corrosion is attributed to the combination of reinforcing fibers, such as fiberglass or carbon fiber, and a resin matrix that securely binds these fibers together. The resin matrix, typically a thermosetting polymer like polyester or epoxy, forms a protective barrier that shields the profiles from corrosive substances. Nitric acid is renowned for its capacity to corrode and deteriorate metals. Nonetheless, FRP pultrusion profiles exhibit exceptional resistance to nitric acid due to the inert nature of the composite materials employed. The reinforcing fibers utilized in FRP profiles do not react with nitric acid, while the resin matrix effectively prevents the acid from reaching and corroding the fibers by acting as a barrier. It is essential to acknowledge that the specific resistance of FRP pultrusion profiles to nitric acid may vary depending on the precise composition of the composite materials utilized, as well as the concentration and temperature of the nitric acid. Therefore, it is always advisable to consult the manufacturer or supplier of FRP profiles to ensure their compatibility with nitric acid in specific applications.

Send your message to us

FRP Pultrusion Profiles - FRP Gratings, Fiberglass Solid Grilles & Water-Resistant Steel Grating in Various Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords