FRP Pultrusion Profiles - Pultruded Grating Walkway Floor & Pultruded Platform

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

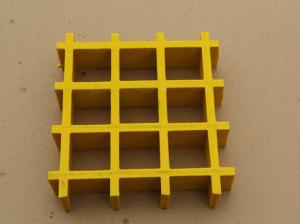

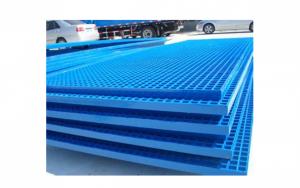

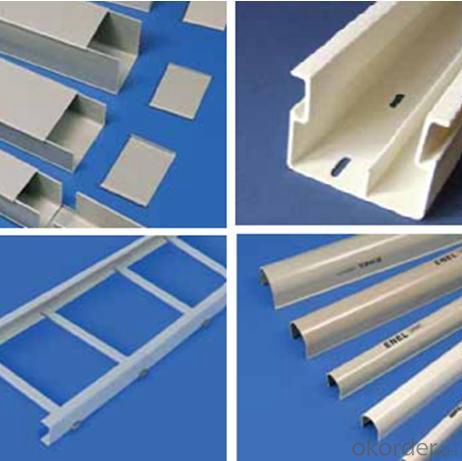

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

FEATURES

1.Electrically and thermally non-conductive

2.Ultra-violet resistant

3.Provided in a number of gratings thickness and panel sizes with many types of mesh size

4.Offers bi-directional strength characteristic

5.Impact resistance

6.insulationt

SPECIFICATIONS

Name | Ring Lock scaffolding |

Size | Ø48.3*3.25*1000/2000/3000 or as your request |

Main Material | Q195,Q235,Q345 |

Surface Treatment | HDG, dip painting, galvanize, Powder Coating |

Application | Slab support, working platform, construction, warehouse storage shelf, stage |

Color | Silver, Dark red or as request |

Certificate | SGS, EN12810.ISO |

Service | OEM Service available |

PICTURES

- Q: Can FRP pultrusion profiles be used in the renewable energy sector?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can definitely be used in the renewable energy sector. FRP pultrusion profiles offer several advantages that make them well-suited for various applications within the sector. One key advantage of FRP pultrusion profiles is their excellent strength-to-weight ratio. As renewable energy projects often involve the installation and maintenance of large structures, such as wind turbine blades or solar panel frames, the lightweight nature of FRP profiles can significantly reduce transportation and installation costs. Additionally, their high strength allows for better load-bearing capabilities, ensuring the structural integrity and longevity of renewable energy infrastructure. Another benefit of FRP pultrusion profiles is their corrosion resistance. In the renewable energy sector, structures are often exposed to harsh environments, such as offshore wind farms or solar installations in coastal areas. The corrosion-resistant properties of FRP profiles make them an ideal choice, as they are not susceptible to rust or degradation caused by exposure to moisture, saltwater, or chemicals commonly found in these environments. This characteristic significantly reduces maintenance and replacement costs, making FRP profiles a cost-effective solution for the renewable energy sector. Furthermore, FRP pultrusion profiles offer design flexibility. They can be custom-engineered to meet specific project requirements, allowing for complex shapes and sizes. This versatility enables the creation of innovative and efficient renewable energy solutions, such as aerodynamically optimized wind turbine blades or lightweight support structures for solar panels. In summary, FRP pultrusion profiles are well-suited for the renewable energy sector due to their lightweight, high strength, corrosion resistance, and design flexibility. These characteristics make them an excellent choice for various applications, including wind energy, solar power, hydroelectric projects, and more.

- Q: What is the lifespan of FRP pultrusion profiles?

- The lifespan of FRP pultrusion profiles can vary depending on various factors such as the quality of the material, environmental conditions, and the application they are used in. However, in general, FRP pultrusion profiles have a long lifespan and can last for several decades with proper maintenance and care.

- Q: Can FRP pultrusion profiles be used in the construction of wind turbine blades?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of wind turbine blades. FRP pultrusion profiles offer several advantages that make them suitable for wind turbine blade construction. Firstly, FRP pultrusion profiles are lightweight yet strong, which is an important characteristic in wind turbine blades as they need to be able to withstand the aerodynamic forces exerted by the wind. The high strength-to-weight ratio of FRP pultrusion profiles allows for the construction of longer and more efficient blades. Additionally, FRP pultrusion profiles have excellent corrosion resistance properties, which is crucial for wind turbines exposed to harsh weather conditions. Unlike traditional materials like steel, FRP does not corrode, ensuring a longer service life for the wind turbine blades. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements. This flexibility allows for the optimization of blade performance by tailoring the shape, thickness, and stiffness of the profiles to maximize energy capture and minimize fatigue. Furthermore, FRP pultrusion profiles offer good fatigue resistance, meaning they can withstand repeated loading cycles without experiencing significant degradation in performance. This is essential for wind turbine blades that are subjected to cyclic loading due to wind gusts and changes in wind direction. Finally, FRP pultrusion profiles are also electrically non-conductive, which is advantageous for wind turbine blades as it eliminates the risk of electrical discharge during operation. Overall, the lightweight, strong, corrosion-resistant, and customizable nature of FRP pultrusion profiles make them an excellent choice for the construction of wind turbine blades, contributing to the development of more efficient and durable wind energy systems.

- Q: What are the environmental benefits of using FRP pultrusion profiles?

- There are several environmental benefits associated with using FRP (Fiber Reinforced Polymer) pultrusion profiles. Firstly, FRP pultrusion profiles are lightweight and have a high strength-to-weight ratio. This means that less material is required to achieve the same structural integrity as traditional materials like steel or concrete. As a result, the production and transportation of FRP profiles consume less energy and generate fewer greenhouse gas emissions. Additionally, FRP pultrusion profiles are highly durable and resistant to corrosion, which increases their lifespan and reduces the need for frequent replacements. This not only saves resources but also reduces the amount of waste that ends up in landfills or requires recycling. Furthermore, FRP is non-conductive, making it an excellent alternative to metals in electrical applications. This property eliminates the risk of electrical accidents and reduces the need for insulation, which often involves hazardous materials. Moreover, the manufacturing process of FRP pultrusion profiles typically requires lower energy inputs compared to other materials. The pultrusion process itself is energy-efficient, and the raw materials used in FRP production, such as resins and fibers, can be sourced from renewable or recycled sources. Lastly, FRP pultrusion profiles are chemically inert and do not release harmful substances into the environment. This characteristic makes them suitable for various applications, such as water treatment plants, where avoiding chemical leaching is crucial for maintaining water quality. In conclusion, the environmental benefits of using FRP pultrusion profiles include reduced energy consumption, lower greenhouse gas emissions, extended product lifespan, decreased waste generation, decreased reliance on non-renewable resources, and minimized chemical leaching. These advantages make FRP a sustainable and eco-friendly choice for a wide range of industries.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of boat hulls?

- Boat hulls can be effectively manufactured using FRP pultrusion profiles. These profiles possess numerous advantages that render them perfect for constructing boat hulls. Firstly, FRP pultrusion profiles are not only lightweight but also exceptionally sturdy and durable. Consequently, they are well-suited for boat hulls as their lightweight nature enhances fuel efficiency and enables increased speed. Moreover, their impressive strength-to-weight ratio guarantees that the boat can endure the rigors of the water without compromising its structural integrity. Secondly, FRP pultrusion profiles exhibit exceptional resistance to corrosion. This characteristic is of utmost importance for boat hulls, which are constantly exposed to water, salt, and other corrosive agents. The corrosion resistance of FRP pultrusion profiles ensures that the boat hull remains intact and maintains its performance over time, thus minimizing the need for frequent maintenance and repairs. Furthermore, FRP pultrusion profiles offer great design flexibility. They can be effortlessly molded into diverse shapes and sizes, thereby facilitating customization and optimization of boat hull designs. This flexibility empowers boat manufacturers to create hulls that are both functional and visually appealing. In addition to their strength, durability, corrosion resistance, and design flexibility, FRP pultrusion profiles also possess excellent electrical and thermal insulation properties. These properties are particularly important for boat hulls as they effectively prevent the passage of electrical currents and heat through the hull, thereby ensuring the safety and comfort of passengers and crew. Overall, FRP pultrusion profiles present an outstanding solution for boat hull manufacturing. Their lightweight, robust, and corrosion-resistant attributes, in conjunction with their design flexibility and insulation capabilities, make them an ideal choice for boat manufacturers seeking to produce high-performance and long-lasting vessels.

- Q: Are FRP pultrusion profiles resistant to impact from flying debris?

- Yes, FRP pultrusion profiles are highly resistant to impact from flying debris. Thanks to their reinforced fiberglass construction, these profiles have exceptional strength and durability, making them capable of withstanding significant impact forces without incurring damage.

- Q: Are FRP pultrusion profiles resistant to hydrochloric acid?

- FRP pultrusion profiles are generally resistant to hydrochloric acid. The corrosion resistance of FRP (Fiber Reinforced Polymer) materials varies depending on the specific resin and fiber used in the manufacturing process. However, most FRP pultrusion profiles are designed to withstand exposure to a wide range of chemicals, including hydrochloric acid. The corrosion resistance of FRP is attributed to the chemical inertness of the resin matrix, which is typically made of polyester, vinyl ester, or epoxy. These resins provide a protective barrier against chemical attack and allow FRP profiles to maintain their structural integrity even in harsh environments. That being said, the level of resistance can vary depending on the concentration and temperature of the hydrochloric acid. In highly concentrated or elevated temperature conditions, the resistance may be reduced. It is always advisable to consult the manufacturer's specifications or seek expert advice to ensure the suitability of FRP pultrusion profiles for specific acid concentration and temperature ranges. Overall, FRP pultrusion profiles are known for their excellent chemical resistance, and they are often chosen for applications where exposure to acids or corrosive environments is expected.

- Q: What are the main uses of pultruded glass fiber reinforced plastic extrusions?

- The village shopping malls, livestock pens, Birdhouse wall gate, greenhouse structure, supporting member, rattan shelf, water tank etc.. The countryside is a potential big shopping mall, but the factors of bidding restrict its development.

- Q: What types of materials are commonly used in FRP pultrusion?

- Fiber Reinforced Polymer (FRP) pultrusion is a manufacturing process that involves pulling continuous fibers through a resin bath and then through a heated die, resulting in a composite material with high strength and stiffness. Various types of materials are commonly used in FRP pultrusion, depending on the specific application and desired properties. 1. Fibers: The most commonly used fibers in FRP pultrusion are fiberglass (glass-reinforced polymer) and carbon fibers. Fiberglass is cost-effective, lightweight, and offers good strength and corrosion resistance. Carbon fibers, on the other hand, provide exceptional strength, stiffness, and lightweight properties but are more expensive. 2. Resins: The resin matrix used in FRP pultrusion provides the material with rigidity and protection against environmental factors. Polyester resin is the most common resin used due to its low cost, ease of handling, and good mechanical properties. Vinyl ester resin is another popular choice, offering improved chemical resistance and heat tolerance compared to polyester. Epoxy resin is used when high strength and durability are required. 3. Additives: Various additives can be incorporated into the resin matrix to enhance specific properties of the FRP pultruded product. UV stabilizers are commonly used to protect against ultraviolet degradation. Flame retardants can be added to increase fire resistance. Other additives like pigments, fillers, and mold release agents may also be used to achieve desired aesthetics and processing characteristics. By selecting the appropriate combination of fibers, resins, and additives, FRP pultrusion can produce a wide range of composite materials with tailored properties to meet specific application requirements. This versatility in material selection is one of the key advantages of FRP pultrusion, making it suitable for a variety of industries such as construction, infrastructure, aerospace, automotive, and marine.

- Q: Are FRP pultrusion profiles resistant to hail or impact damage?

- Yes, FRP pultrusion profiles are typically resistant to hail or impact damage due to their strong and durable composition. The combination of reinforced fibers and resin matrix make them highly resistant to external forces, ensuring longevity and minimal damage in the event of hail or impact.

Send your message to us

FRP Pultrusion Profiles - Pultruded Grating Walkway Floor & Pultruded Platform

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords