Fiberglass FRP Pultrusion Profile I Beam with Good Features

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

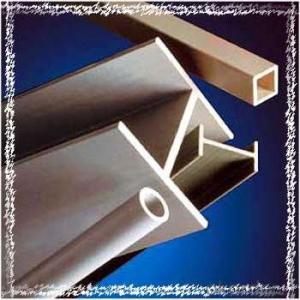

Pultrusion process is a mechanized process for FRP composites involves pulling a collection of fibers in the form of roving mat or fabric through a resin bath and then through a heated die to cure the resin, and then take shapes of profiles. FRP pultruded profiles are more than a kind of structure, which is very designable. Changing the choice of the materials and designs of the lamination process can make special properties for it.

Product Performance:

• Non-magnetism and non-conductive

• Very designable, cut discretionarily

• Easy of installation and dimensional stability

• Long service life and maintenance-free

• Bright color and good appearance

PROFILE TYPE

By changing different shapes of the mould (die), this production line can produce different profiles or rods. The following list is some products photos for reference.

No. | Item | No. | Item |

1 | Rectangular tube | 9 | Cable tray |

2 | Square tube | 10 | Handrail |

3 | Round tube | 11 | Profile for door & window |

4 | Channel | 12 | Guardrail |

5 | I-beam | 13 | End fitting of Radome |

6 | Angel | 14 | Shaft of the umbrella& tent |

7 | Epoxy rod | 15 | Profile for bridge |

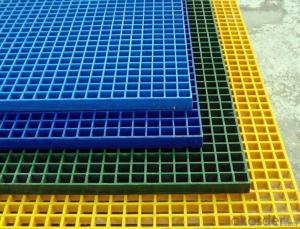

8 | Platform and ladder | 16 | Ladder |

Application

The FRP channel products can resist corrosion from various gas or liquid such as acid,alkali,organic solvent and compound.They can be used as ladder material,and used in the electricity industries. It can be widely use in railing, bracket of water circulation tower, sport equipment, tool handle, bracket of tent and others loading structure components

FAQ:

1.Who will pay for the express cost ?

A: We can support you free samples ,but express cost will be paid by you .

2.How long is the delivery time?

A:within 10-15 days after receiving deposit.

- Q: How to make color steel board room waterproof?

- Waterproof construction technology:The protrusion 1, metal roof (such as chimneys, vents, fan mouth etc.): cut the size and shape of a suitable sewing polyester cloth, and according to the technical requirements of cutting, the protrusion around is coated with a layer of base paint, cut good sewing polyester cloth on it, and then from above with the primary coating full infiltration sewing polyester cloth, ensure no foaming, wrinkle.2, in the well water treatment area with one or two layer top surface coating, coating the surface coating total rate of 35 square meters (two /20 l recommend brushing, keep the total coating rate unchanged).3. The coating rate of single layer coating is 40 M2 /20 litre, and the utilization ratio of stitched polyester fabric is 90%.

- Q: The fabric is 70%polyester and 30% cotton. I need it red to make a red cape for a Halloween costume. Please help soon!!!

- Cloth dye like Ritz or something is not cheap anymore and you have to heat the water and let it sit and then take it out and wring it out, a far better idea, go and get a remnant at a fabric store, no mess and no falling on the floor, if it gets on tile or something its awful to get out, or go get a cheap sheet or Dollarama etc.

- Q: One of my little cousins has an old stuffed dog from animal alley I believe. Well she‘s slept on it for years now and it‘s lost a lot of stuffing. My cousin is so sad does anyone know how to fix it or where to send it to re-stuff it or anything?

- Stuffing Stuffed Animals

- Q: I ironed a black polyester shirt and i left a shiney iron imprint on the sleeve, can it be removed?

- try washing it again and when you iron it, use a clean cotton cloth between the iron and the shirt.

- Q: Why should plastic material be reinforced with glass fiber?

- Increase strength and toughness, plastic is plastic, after all, many properties can not keep up, just like building a house, why does it add rebar?

- Q: oldest fiberglass boat made?

- Owens-Corning had been experimenting with fiberglass cloth and resin combinations to create structural elements for airplanes. By 1942, the company was turning out fiberglass and polyester airplane parts for the war effort. In Toledo, Ray Greene, who had studied plastics while a student at Ohio State, had been working with Owens-Corning on fiberglass composites. He had made composite boats as early as 1937, but was searching for just the right plastic to use for boats. He received a shipment of the polyester resin in 1942 and produced a daysailer. Others followed suit. Dan says, B.B. Swan made a small fiberglass catboat in1947. Carl Beetle built fiberglass boats at a GE plant in Pittsfield, Mass. He exhibited his fiberglass boat at a show in January 1947. The first sailing auxiliary made from fiberglass appeared in 1951. It was called the Arion, a 42-foot ketch. states Spurr. It was a one-off design by Sidney Herreshoff. Then Fred Coleman's Bounty II came out in 1956. More information is at the link below:

- Q: I‘m at work right now, and my dress is just clinging to me! Any ideas how to get rid of it?

- ok an axle is where you kind of do a turn with your leg bent. ket me explain. ok easiest is to start off in a shanae. shanae and then bring your arms out and pull them in while bending your right leg and jumpign into the air while bringing your left leg up to your right knee. really easy once you get the hang of it

- Q: Assuming they are all the same thickness.CottonCotton/NylonCotton/PolyesterDoes color make a difference in stopping UV rays?I know it does with visible rays but what about UV?Additional DetailsAlso a 2nd part to the question.Answer if you know.What is better at stopping UV raysRipstop or Twill Assuming it‘s on the same fabric and everything.Does that make much difference?

- In doing research on UV rays I found that dark colors block UV rays better than light colors and Polyester blocks UV better than cotton. The right cloth which is the right color is better than chemical sun block according to my research.

- Q: i thinking a resin or glue would harden the outer polyester type fabric of the case but i‘m not certain

- My problem with hardening a cloth case would be holding the shape while the material hardened without getting the guitar wet from the glue's water or the resin's solvent. And cloth cases tend to fit so closely that as you are putting the guitar in, they bend and change shape to fit and if the outer surface is stiff, they are less likely to do that. I think you would be better off either shopping around for choices on hard shell cases, perhaps for one that is lighter than the most common ones or looking to make a shell of thin stiff plastic material that your cloth case would slide inside to pad the guitar.

Send your message to us

Fiberglass FRP Pultrusion Profile I Beam with Good Features

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords