Fiberglass Best Composites FRP Gratings

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

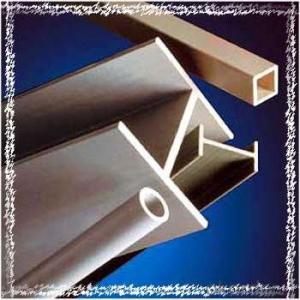

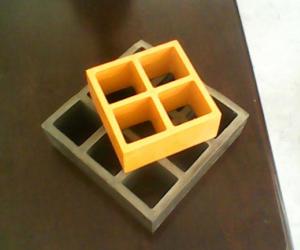

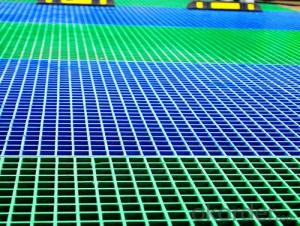

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

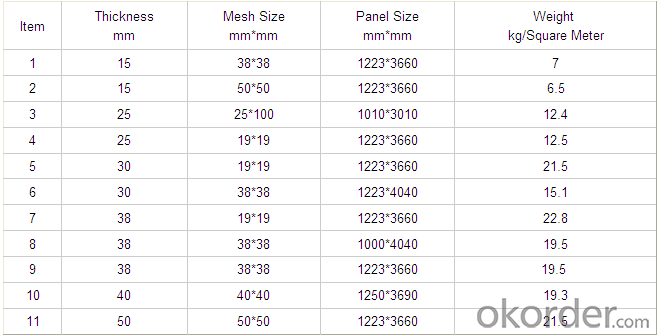

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

high strength

long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

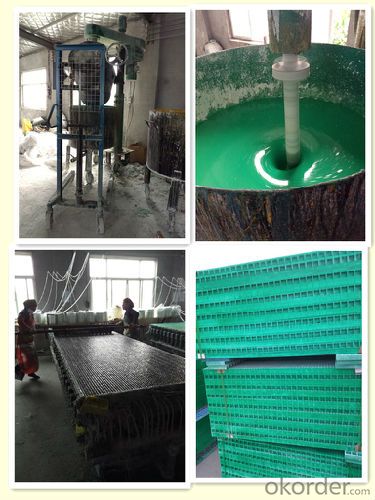

PROCESS

FACTORY

- Q: It's a vintage, 70s, women's, polyester, long sleeved shirt. It's tan coloured with scattered children's pictures all over. Because of it's colour, everything I wear it with makes it look like a dirty white shirt (in a bad way) and incredibly dull and brown.What should I wear with it and in what colours?

- we wear shirt inside the inner wear we use the polythene cloths

- Q: I ironed a black polyester shirt and i left a shiney iron imprint on the sleeve, can it be removed?

- try washing it again and when you iron it, use a clean cotton cloth between the iron and the shirt.

- Q: What temperature do I set the washing machine to if I am washing 50% cotton, 50% polyester a sweatshirt?

- Cold is the best to avoid shrinking and fading. If you have a spot on it, treat that before washing; don't wash the whole thing in warm or hot just to remove marks.

- Q: I‘m making a mask with clay that is supposed to go in the oven. I can‘t take the clay off the face or it will break. What should I do? Put it in the oven?? Will the mask melt? Oh and the clay isnt air dry

- They are the same Offroad or in snow. 4WD(4x4) can turn to 2WD when you want to. AWD is always on. You can never switch to 2WD.

- Q: What is the difference between silicone rubber fiber glass and silicone glass fiber sleeving?

- The base material is glass fiber, one is coated with silicone rubber, the other is coated with organosilicon resin, and the insulation performance is different

- Q: When I purchased my formal dress, I was told that I could use double sided tape to hem it because it is cheaper than paying to get it sewn. Has anyone done this before? Is there a special fabric double sided tape? If so, where can I find it?

- Yes you can use stitch witchery it is double sided and when you heat it it sticks to both sides also there is fabric glue which works well but needs 24 hours to dry with something like books on top to keep down hemming truthfully is the best because depending on dancing etc the others may fail just keep that in mindand some dry cleaners hem at a small fee

- Q: Dryer stops after about 10min, before clothes are dry, signals 1 beep. If I restart,it will beeps again and stops. I need to let it sit for 30min, then it will run for another 10min or so. It heats up well. I replaced the dry-sensor, no help.I have a Whirlpool Electric Dryer (GEQ9858JQ0).

- Dryers can have significant reactions based on several factors. Have you cleaned your lint filter-not just pulling off the lint, but washing it in soap and water? An invisible film, caused primarily by fabric softener sheets can plug the lint filter's little holes and you won't even know they're clogged. Have you cleaned well deep inside of the machine? Tons of lint bypass the filter and gets down into the area of the machine where the heating elements are, regardless of the type of fuel used to operate your machine. Also a huge fire hazard of lint continues to accumulate in those areas. Finally, the type of fabric being dried can affect the sensors. The most likely to be problematic is anything made of Microfiber (regardless of whether it's a clothing item or a cleaning cloth), followed closely by other varieties of Polyester. ALL of these factors can cause the dryer to artificially overheat, causing the sensor to shut the machine off to prevent further damage.

- Q: that is mostly used in jewelry making.I think. it starts out a liquid, then drys completely clear, and looks a little like glass and is used sometimes to make the image underneath look larger.

- Epoxy resin Casting resin

- Q: What is the chemical name for the polyesters used in surface coating of tiles in order to make the tile suitable for sublimation printingIf possible please tell me the manufacturer of these products - not interested in the distributors

- the average size is 26 for mountain bikes and 27 for road bikes,just won has no clue what their talking about,according to them your 27 wheel has a metric equivalent size of 700cm,that would make the wheel 7 metres wide(idiot),the correct size is 700c which means 700mm from rim to rim!

Send your message to us

Fiberglass Best Composites FRP Gratings

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords