FRP flange,tee,elbow,reducer,cap,Pumping Station,cover plate and so on customized FRP fittings

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

FRP Integrated prefabricated pump station

Product features:

1. Very little space

The integrated pump station is buried underground without pump station civil construction on the ground and does not occupy the land index. The buried structure makes it integrated with the surrounding environment, beautiful and generous; Garden pump station can be built, beautiful environment.

2. High integration

As an integrated unit, its complete set provides: prefabricated simplified, submersible sewage pump, piping system, pulverized grille, control system, lifting device, exhaust device and other parts, with large capacity safety redundant fixed protection to ensure the perfect match of all parts, can fully meet the quality requirements of users.

3, Strong, beautiful

The main structure of the equipment is made of fiber wound FRP, which is twice as strong as traditional laminated FRP after static pressure and deformation resistance calculation. It can completely resist tearing, corrosion and other destructive force, so it is strong, durable and durable.

4. Short engineering cycle

This series of products are supplied as finished products. The installation and debugging of each component is completed in the factory. The installation and debugging time required after the goods arrive at the site is greatly shortened compared with the traditional pump station. The workload of civil engineering is about 1/10 of that of the traditional concrete pump station, which greatly shortens the whole project cycle.

5, Efficient environmental protection, cost saving

The self-distribution control operation system ensures that the pump runs automatically and efficiently according to the volume of incoming water. The internal flow state is good. The system can be self-cleaned without precipitation, airtight without odor, and meets the requirements of environmental protection. Compared with traditional concrete pump station, this series of precast pump stations can save 20%~30% of the cost and cover a small area.

6, Automatic control

The supporting submersible pump adopts pressure sensor or liquid level floating ball to automatically control the start and stop; Pulverized grille is normally open, in case of large objects can automatically turn over, so the whole pump station automatic operation, without special personnel on duty.At the same time, it can adopt intelligent control of mobile communication, with remote monitoring platform, man-machine dialogue interface display and mobile terminal control.

7, Convenient installation and maintenance

The pump and grille can be lifted in or out from the top.

8, Long service life

Self-cleaning thin shell shaft base and smooth inner wall ensure long service and no need. Maintenance; Pumps, grilles and pipes are made of anticorrosive materials with long service life.

9. Function expansion

It can be used with integrated sewage treatment device to achieve sewage treatment standards. Discharge or reuse of sewage.

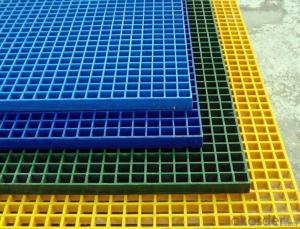

FRP cover plate

Brief introduction of FRP cover plate:

FRP cover plate is mainly used in system engineering, petrochemical and other industries. Due to the characteristics of corrosion resistance, light weight, high strength, aging resistance, designability, easy installation, long service life and so on, GLASS fiber reinforced plastic cover plate has been widely used in the development of modern society. According to the requirements of users and the size of the sewage tank, can be made of arc cover plate and cover plate and other shapes. Its color can also be made into a variety of colors according to the requirements of users, to meet the different needs of users.

Product features:

1, Wear-resistant skid performance is outstanding:

in the process of production will be anti-skid and wear-resistant processing. Its anti-skid and wear resistance is far better than the general metal cover plate and wood cover plate, plastic cover plate, etc.. Specifically, the anti-skid treatment and wear-resistant treatment of FRP cover plate are introduced in detail in the following chapters.

2, Good sealing performance, high safety:

Compared with the metal cover plate with poor corrosion resistance and the wood cover plate with poor material, the sealing performance of FRP cover plate is first-class. And it has many characteristics of non-conductive, non-thermal conductivity and high corrosion resistance.

3, High temperature resistance, flame retardant performance:

All FRP products have strong flame retardant properties, mainly due to the production of FRP products raw material resin. Although the type of resin is different, it can be divided into many kinds, but high temperature resistance is one of the necessary properties of each resin.

4. Excellent aging resistance and corrosion resistance:

Aging is also a manifestation of corrosion, which can be more accurately expressed as chronic corrosion. For example, humid air is a chronic corrosive environment. Metal cover plate placed in the humid air for a long time will be slowly corroded, is commonly known as rust.

5, Long service life, high economic benefit:

In general, the service life of FRP cover plate is more than 50 years. And the service life of metal cover plate is only about 5 years, the service life of wood cover plate is only about 3 years.

FRP cover plate has corrosion flame retardant, solid non-slip, light weight, easy installation, free maintenance, excellent properties such as insulation, than traditional materials such as steel, aluminium, stainless steel and alloy steel to some extent, the advantages of walk is suitable for the operating platform, stairs, the cover board, building decoration and other occasions, in hot and humid easy rust, acid and alkali corrosion and dew in the fields such as high altitude is more has the incomparable role.

FRP Biological deodorant integrated device

Brief introduction of FRP Biological deodorant integrated device:

Biological deodorization is a kind of technology that takes advantage of the adsorption, absorption and degradation functions of microbial cells to odorous substances. The main process is as follows: Through the collection pipe, the exhaust fan will collect the odor to the deodorizing device of the biological filter, the odor will enter the body of the biological filter after humidification by the humidifier, and then the odor will be removed by the adsorption, absorption and degradation of the packing microorganisms. At present, the main methods of biological treatment of odor are: biological soil filter, biological filter and biological drop filter, biological compound deodorization.

Product features:

1) modular, standardized engineering design, no secondary pollution.

2), can simultaneously handle the waste gas containing a variety of pollution, high removal efficiency, fast reaction speed.

3) Glass steel material, beautiful appearance, strong corrosion resistance, long service life.

4) Short processing time and high efficiency. The purification can be completed in 5-10 seconds, and the comprehensive efficiency can reach more than 95%.

5) Biological strains hang on the membrane once, with many strains and short inoculation time.

6), low construction cost, low operating costs, no need to add agents.

7), the use of composite filter material, large surface area, good permeability, not hardening, long service life.

8) PLC control, high degree of automation.

Product Application:

1) Composting, landfill and incineration for power generation. Garbage leachate regulating pool, garbage transfer station, garbage composting;

2) Sewage pump station of sewage treatment plant, inlet grille, aerated sand settling tank, primary settling tank, sludge dewatering workshop;

3) Coatings and paint, coking, chemical, pharmaceutical, rubber, plastic, paint coatings, printing and dyeing, leather, organic pigment and synthetic materials plant, pharmaceutical, dye, pesticide and fermentation petroleum chemical industry, shoe factory, printing factory, paper mill, gas stations, livestock, feed processing, the stench gas such as waste treatment and exhaust gas purification and treatment.

FRP fittings:

It is mainly made of FRP material, which has good process properties: light weight, high strength and corrosion resistance.FRP fittings produced by our company mainly include: FRP flange, FRP tee,FRP elbow,FRP reducer,FRP cap etc.As the accessories of water delivery pipe,distribution pipe, sewage pipe, rainwater pipe, agricultural irrigation pipe and other FRP pipelines, they can be used according to the process design required by the project installation.

- Q: How to install the wires, plastic pipes, pipes, hard, all set not go in

- Is the first line laying tubing, after threading.

- Q: Why is it forbidden to use polyvinyl chloride fibre glass pipes as wire conduits and buried in the floor?

- After completion of the project, use 1 or 1.2 steel wire through the box, use the PVC86 type nut, use 20 glue, and use PVC glue. Double commissure, box 146.

- Q: What can be insulated from the outside of the wire?

- Pvc4 line slot is fixed to the maximum from the jar on the wall, and finally put the wire cover and insulation way too much, this is the most simple and most practical, but need to punch holes in the wall without impact drill, impact drill, with the 4 points PVC or pvc4 line pipe hose can

- Q: PPR antibacterial pipe and glass fiber pipe for home decoration

- Antibacterial does not kill bacteria completely, but inhibits the growth of bacteria.Glass fiber pipe is called "glass fiber steady state tube": ordinary PPR is easy to deform when heated, especially when the transverse tube is long, it will collapse. In order to increase the pipe generally steady pipe middle layer is joining metal material, but the weld metal and PPR is not very good time long easy delamination, and aluminum layer construction construction would need to be stripped out of trouble. The glass fiber (which is commonly referred to as glass fiber reinforced plastic) is added in the middle layer of the glass fiber stabilizing tube. The strength is increased and the solubility of PPR is very good. The phenomenon of delamination can not occur. It can be directly heated and has no need of peeling and convenient construction

- Q: What is the advantage of adding fiberglass in pipes?

- Increase the strength of the pipe wall, according to different layers to increase the pressure value of the pipe.

- Q: Can the glass fiber pipe be riveted in conjunction with the other parts?

- Day is the lantern light we said, generally used in large shopping malls, office buildings and other public places, home use less, ceiling parts reflecting aluminum substrate LED lamp lamp ceiling lamp shell ceiling ceiling lamp cover

- Q: What are the advantages of glass fiber hot water pipes relative to other hot water pipes?

- PPR glass fiber pipe is a new generation of composite pipes, which combines the advantages of PPR and glass fiber compression, temperature resistance and low linear expansion characteristics. Glass fiber PPR tube antibacterial tube is divided into three layers, the inner layer is antibacterial PPR material, adding PAG - 40 silver ion antibacterial agent, with high spectrum, bactericidal efficacy, non-toxic, pollution-free, sanitary, clean and so on.

- Q: PP-R what is the pressure of the heat pipe?

- Under normal circumstances, 8 kilograms is no problem

- Q: How about using fiberglass pipes to decorate the water pipes in the house?

- I think the general home use, or the use of Jinde or Wuhan Taurus tube, you can reach the general family requirements, sometimes excessive requirements, but the actual application may not be able to reflect high performance, and I hope to help you

- Q: Which is good, PPR aluminum pipe and PPR glass fiber pipe?

- PPR glass fiber pipe is based on the PPR to add a layer of glass fiber, improve its hardness. PPR aluminum plastic pipe is based on the PPR, adding a layer of aluminum, metal is certainly better than glass fiber, glass fiber manufacturing process is also simpler than aluminum, the price should be cheaper. But the disadvantage of aluminum is easy to oxidation, especially aluminum, PPR and pipe fittings after welding directly into the water, it is easy to oxidation, and after one or two years, its quality has become an anti trend. If it is a steady pipe, the aluminum is removed when it is welded, that can solve the problem, but the installation is troublesome and the price is relatively more expensive.

Send your message to us

FRP flange,tee,elbow,reducer,cap,Pumping Station,cover plate and so on customized FRP fittings

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.