Fiberglass Reinforced Plastic (FRP) Grating 30/1220x3660

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

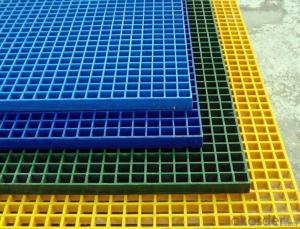

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

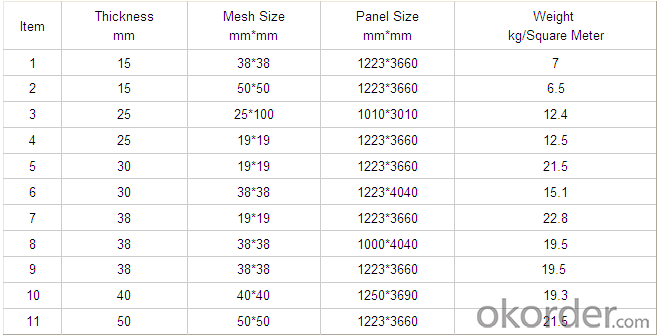

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

high strength

long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

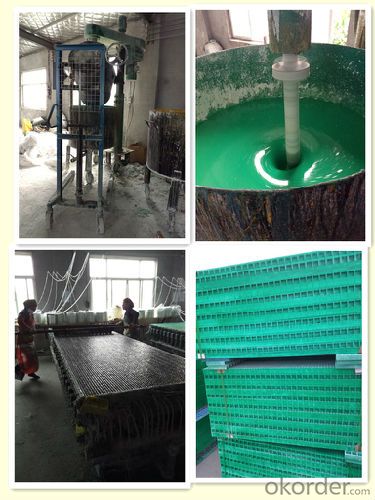

PROCESS

FACTORY

- Q: I‘m trying to get understand clothing more so I can appraise the value of clothing when I go to a store. I know there‘s more to fabric type, like the stitching for example but this will get me started.CottonDenimWoolMicrofiberRayonPolyesterLinenNylonAcrylicAcetateBark ClothCheeseclothChiffonCorduroyGeorgetteHempJuteMorhairSilkVelvetVeniseA BlendI actually got these off a website.

- This Site Might Help You. RE: Can you list the types of fabric in clothing from best to worst? I'm trying to get understand clothing more so I can appraise the value of clothing when I go to a store. I know there's more to fabric type, like the stitching for example but this will get me.

- Q: Glass steel tile production and glass fiber reinforced plastic production is everything?

- With continuous molding, infinite, lightweight and high strength, aging resistance, light, flame retardant, precise size, smooth surface, random coloring, free maintenance, environmental protection, products are widely used in large buildings, modern steel structure color pressure plate, greenhouses, stadiums, aquaculture and other places.

- Q: and if you can tell me how polyester keeps you warm

- I insure everything with State Farm. Car, Motorcycle, Boat, Camper, million dollar over ride. I had a motorcycle accident ten years ago when a drunk hit me with a car. State Farm paid off with no problem.

- Q: What can I do with the dirty ones until I wash them? I have been throwing them in the washing machine with water but, it is not working out when I have to wash other clothing. I have a diaper pail and it said suitable for cloth diapers when I bought it. Do I just throw them in there or put something like water in there? I am clueless. I wash diapers about every 3-4 days. Also how should I wash them? I have been using laundry soap and some bleach but, I heard that is not good to do.

- RE: where to keep the dirty dipes I have a hamper that I throw them in, and it is lined with a mesh laundry bag which I got from target for $2. The top is not sealed shut, it is one of those swinging lids. I either use a diaper sprayer or a scrub brush for the poops, so I do not throw poopy diapers in there (ever). If you have a younger baby who is exclusively breastfed (no solids), you can just throw the diapers in the dry pail without rinsing. When you do a load of dipes, make sure you also wash the laundry bag (!) I did not notice much of a smell when he was younger. ((now, I have to wash every 2 cause his urine smells strongly like ammonia!!)). I would not recommend the wet pail method. It is actually a bit of a drowning hazard to have around the house and it can get EXTREMELY stinky. That water will grow and fester all sorts of bacteria and can be quite disgusting. The dry pail method is much better. Trust me, I have tried both :) RE: washing the diapers I would recommend using an additive free detergent with one cup of white vinegar. I always use Bio-Pack or Charlie's Soap (the dry powder). I buy the Bio-Pack in bulk at the local organic market and it is very cheap. Charlie's Soap is also cheap if you buy wholesale (I think you can buy a five pound bucket, you only need a tablespoon for each load). Bio-Kleen is also really good, and is a pretty good value too (you can get it at Whole Foods). I would not recommend using bleach at all. Vinegar works much better, and it much safer and earth friendly :) If things get really gruesome, try 1c vinegar + 1 tbsp baking soda. BTW: I use unbleached cotton prefolds. I would recommend them any day over Bum Geniuses and other pockets (many of which are lined with polyester). Just my opinion. They are so easy to care for, and so much better for baby's skin.

- Q: advice for cotton polyester baseball cap

- it really depends on fabric of your baseball cap, as we know ,most of baseball caps were made of cotton twill, this kind of baseball cap if washing many times , the color will fade quickly. The correct way of cleaning the cap, is to use the transparent tape to stick it again and again, this will remove the dirt. If you really need to wash it, just keep the cap strait on your hand and use wash it surface, do not put it all on water, because this will make your cap out of shape soon.

- Q: I‘m allergic to cotton. It gives me hives if it touches my skin. I get hives just from touching money (because apparently is made with rag paper that is made with scraps of cloth).Jeans and most T shirts are out. What can a teenage male wear that they can buy at a normal store, which contains NO cotton and doesn‘t look dorky? My Dad tried to send me to school with a polyester leisure suit, but I look ridiculous.

- Sports stuff that has no Cotton in it but i don't see this as a good permanent fix because how will you take a girls shirt off or come in contact with other human beings that are wearing shirts.

- Q: I graduate in two weeks. I picked up my gown today, made of 100% polyester, and its badly wrinkled from the package. There are no care instructions. How do I iron out the wrinkles without damaging the poly? Doesn‘t it melt easily?

- low beam one light, high beam two lights.

- Q: How much is the ceiling tile?

- The leakage reasons of the glazed tile roof, roof tile floor due to pouring large and steep slope, the actual construction has certain difficulty, therefore lead to local vibration of glazed tile floor, there is no dense bee hole phenomenon, coupled with the glazed tile floor without doing waterproof treatment, caused directly by the rain after the glazed tile seam into the floor tile into the room. Glazed tile roof leakage Water Leakage the situation is more complex, involving tile roof and eaves gutter, etc. out of roof structure waterproof.

Send your message to us

Fiberglass Reinforced Plastic (FRP) Grating 30/1220x3660

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords