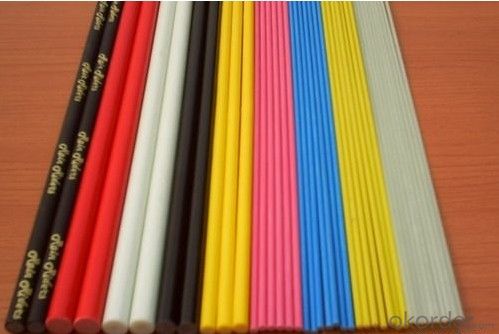

FRP Pultrusion Profiles - Excellent Pultruded Fiberglass Stake

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Excellent Pultruded Fiberglass Stake:

1.Good heat resistance

2.High insulation

3.Easy to cut and install

Characteristics of Excellent Pultruded Fiberglass Stake:

Exceptional chemical and corrosion resistance – Composites offers superior resistance to acid, salt, alkali and electrochemical environment

Superior strength to weight ratio compared to steel or aluminium

Lightweight and manageable - Composites has a specific gravity one quarter that of steel and two thirds that of aluminium

Non-conductive - excellent electrical and thermal insulation

Excellent cost performance - low installation costs, long service life and minimal maintenance all combine to provide cost effective solutions

The Pultrusion Process of Excellent Pultruded Fiberglass Stake: |

Pultrusion is a manufacturing process for producing continuous lengths of reinforced polymer structural shapes with constant cross-sections. Raw materials are a liquid resin mixture (containing resin, fillers and specialized additives) and flexible textile reinforcing fibers. The process involves pulling these raw materials (rather than pushing, as is the case in extrusion) through a heated steel forming die using a continuous pulling device. |

- Q: How is FRP pultrusion different from other manufacturing processes?

- FRP pultrusion is different from other manufacturing processes in its unique method of producing fiber-reinforced polymer (FRP) profiles. Unlike traditional processes like extrusion or injection molding, pultrusion involves pulling continuous fibers through a resin bath and then into a heated die, where they are cured and shaped into the desired profile. This continuous and automated process allows for the production of strong, lightweight, and corrosion-resistant FRP profiles with consistent mechanical properties. Additionally, pultrusion enables the incorporation of various fiber orientations and resin systems, making it highly versatile for customized applications.

- Q: Can FRP pultrusion profiles be used in aerospace applications?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in aerospace applications. FRP materials have several advantages that make them suitable for aerospace use. Firstly, they have excellent strength-to-weight ratios, which is crucial in the aerospace industry to reduce weight and enhance fuel efficiency. Secondly, FRP materials exhibit high corrosion resistance, making them suitable for prolonged exposure to harsh environments, such as high altitude and extreme temperatures. Additionally, FRP pultrusion profiles offer design flexibility, allowing for complex shapes and geometries to be manufactured. This flexibility enables aerospace engineers to tailor the profiles to specific requirements and optimize performance. Furthermore, FRP materials have low thermal conductivity, which helps in insulation applications and reducing heat transfer. Lastly, FRP pultrusion profiles have demonstrated good fatigue resistance, which is essential for aerospace applications subjected to cyclic loading. Overall, these properties make FRP pultrusion profiles a viable choice for various aerospace components, including structural members, interior parts, and electrical enclosures.

- Q: Are FRP pultrusion profiles resistant to vibration or shock?

- FRP pultrusion profiles are highly resistant to vibration and shock. The inherent properties of FRP (Fiber Reinforced Polymer) materials make them ideal for applications requiring durability and strength under dynamic loading conditions. The composition of FRP profiles, which typically include a combination of reinforcing fibers and a resin matrix, provides excellent stiffness and damping characteristics. This enables FRP pultrusion profiles to effectively absorb and dissipate vibrations and shock forces, preventing damage or degradation. Additionally, the design flexibility of FRP allows for tailored reinforcement and optimization, further enhancing its resistance to vibration and shock. Therefore, FRP pultrusion profiles are a reliable choice for applications where these properties are crucial, such as in aerospace, automotive, marine, and structural engineering industries.

- Q: Do you have any high temperature resistant resin made of pultruded glass fiber reinforced plastic?

- Unsaturated polyester resin can not meet the high temperature requirements, epoxy resin also needs to be synthesized

- Q: Can FRP pultrusion profiles be used in electrical or telecommunications applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in electrical or telecommunications applications. FRP pultrusion profiles are known for their excellent electrical insulating properties, high strength-to-weight ratio, and corrosion resistance. These characteristics make them suitable for various electrical and telecommunications applications. In electrical applications, FRP pultrusion profiles can be used as electrical insulators, cable trays, busbar supports, and electrical enclosures. They provide insulation and protection against electrical shocks and are often chosen as an alternative to traditional materials like metal or wood due to their non-conductive properties. Additionally, FRP pultrusion profiles are lightweight and easy to install, which further adds to their suitability in electrical applications. In telecommunications applications, FRP pultrusion profiles are used for cable management systems, antenna supports, and equipment enclosures. Similar to electrical applications, the non-conductive nature of FRP pultrusion profiles ensures the safety and reliability of the telecommunications infrastructure. The profiles can also be customized to meet specific design requirements, such as incorporating cable routing channels or mounting brackets for equipment. Furthermore, FRP pultrusion profiles offer excellent resistance to harsh environmental conditions, such as moisture, UV radiation, and chemicals. This makes them ideal for outdoor electrical or telecommunications installations, where exposure to these elements is common. Overall, FRP pultrusion profiles have proven to be a reliable and cost-effective choice for electrical and telecommunications applications, providing insulation, strength, durability, and resistance to environmental factors.

- Q: Are FRP pultrusion profiles resistant to caustic solutions?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to caustic solutions. The combination of the reinforcing fibers and the polymer matrix used in FRP pultrusion provide excellent chemical resistance. Caustic solutions, such as strong alkaline substances, can often corrode or degrade traditional materials like steel or wood. However, FRP pultrusion profiles are highly resistant to chemical attack, making them suitable for applications where exposure to caustic solutions is common. This resistance makes FRP pultrusion profiles an ideal choice for industries such as chemical processing, wastewater treatment, and marine environments where corrosive substances are present. Nonetheless, it is important to consult the manufacturer's specifications and guidelines to ensure that specific caustic solutions are compatible with the particular FRP pultrusion profile being used.

- Q: Are FRP pultrusion profiles resistant to termites or other pests?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are inherently resistant to termites and other pests. Unlike traditional wood or metal materials, FRP profiles do not provide a food source for termites or any other pests. FRP is composed of a combination of reinforced fibers and a polymer matrix, typically made of fiberglass and resin. These materials are not appealing to pests and do not provide any nutritional value, making FRP profiles highly resistant to termite damage or infestation. This resistance to pests is one of the many advantages of using FRP pultrusion profiles in various applications, especially in outdoor or humid environments where termites are commonly found.

- Q: Can FRP pultrusion profiles be used in mining applications?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in mining applications. FRP pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them well-suited for various mining applications. In mining operations, FRP pultrusion profiles can be used for a range of purposes. They can be used for structural support in underground mines, such as in the construction of tunnels, shafts, and mine roofs. Their high strength allows them to withstand heavy loads and provide long-term support. FRP pultrusion profiles can also be used for equipment and machinery support, such as in conveyor systems, pumps, and tanks. Their resistance to corrosion makes them suitable for use in harsh mining environments, where exposure to moisture, chemicals, and abrasive materials is common. Furthermore, FRP pultrusion profiles can be used for safety applications in mining, including handrails, walkways, and grating systems. These profiles can provide reliable and non-slip surfaces, ensuring the safety of workers in mining operations. Overall, FRP pultrusion profiles offer several advantages in mining applications, including their high strength, corrosion resistance, durability, and ease of installation. These qualities make them a viable and cost-effective choice for various mining operations, contributing to improved efficiency and safety in the industry.

- Q: Are FRP pultrusion profiles impact resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally known for their high impact resistance. The combination of reinforcing fibers, such as glass or carbon, with a polymer matrix results in a material that is inherently strong and durable. The pultrusion process further enhances the impact resistance of these profiles by aligning the fibers in the direction of the load, providing optimal strength against impacts. FRP pultrusion profiles also have a high strength-to-weight ratio, which allows them to withstand heavy impacts without significant damage or deformation. This makes them suitable for applications where impact resistance is crucial, such as in construction, transportation, and infrastructure projects. Moreover, FRP pultrusion profiles offer excellent resistance against corrosion, chemicals, and UV radiation, which further contribute to their durability and long-term performance. These profiles can maintain their impact resistance properties even in harsh environments, making them a preferred choice for various industries. However, it is important to note that the specific impact resistance of FRP pultrusion profiles may vary depending on the specific design, composition, and manufacturing process. Therefore, it is recommended to consult with the manufacturer or supplier to ensure the profiles meet the desired impact resistance requirements for a particular application.

- Q: Are FRP pultrusion profiles resistant to fire?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fire. The composition of FRP includes a resin matrix and reinforcing fibers, such as fiberglass or carbon fiber, which provide excellent fire resistance properties. The resin matrix used in FRP typically has a high flame resistance rating, and the reinforcing fibers do not burn easily. As a result, FRP pultrusion profiles have a high ignition temperature and are inherently self-extinguishing, meaning they will not continue to burn once the flame source is removed. Additionally, FRP pultrusion profiles do not release toxic fumes or smoke when exposed to fire, making them a safer alternative to traditional materials like wood or steel. However, it is important to note that the fire resistance of FRP pultrusion profiles can vary depending on the specific resin formulation and reinforcement material used.

Send your message to us

FRP Pultrusion Profiles - Excellent Pultruded Fiberglass Stake

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords