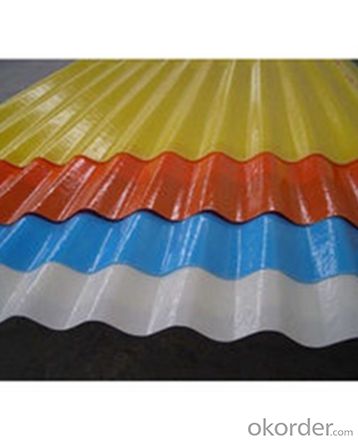

FRP Pultrusion Profiles with Excellent Electromagnetism Property and Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

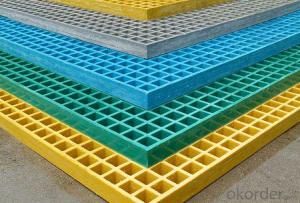

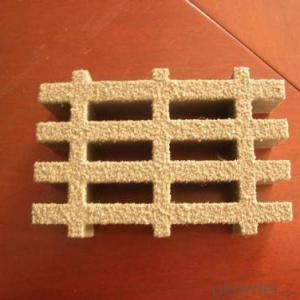

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

PICTURES

- Q: How do FRP pultrusion profiles perform in high-vibration applications?

- High-vibration applications are where FRP (Fiber Reinforced Polymer) pultrusion profiles truly excel. The exceptional properties of FRP materials make them an ideal choice for these situations. To begin with, FRP pultrusion profiles are renowned for their impressive strength-to-weight ratio. Unlike traditional materials like steel or aluminum, FRP profiles are significantly lighter while still possessing remarkable strength and rigidity. This lightweight quality reduces the overall mass of the structure, resulting in lower vibration amplitudes. Furthermore, FRP materials boast outstanding damping characteristics. Damping refers to a material's ability to dissipate energy and decrease vibration amplitudes. In comparison to other materials, FRP pultrusion profiles have a higher damping coefficient, meaning they can more effectively absorb and dissipate vibrations. This minimizes the transmission of vibrations throughout the structure, reducing the risk of resonance and fatigue failure. In addition, FRP pultrusion profiles demonstrate exceptional resistance to fatigue and corrosion. Vibrations can cause cyclic loading, which can lead to fatigue failure over time. However, the inherent properties of FRP materials, including their excellent tensile strength and resistance to environmental factors, make them highly resilient to fatigue and corrosion. This guarantees the longevity and durability of the profiles, even in high-vibration environments. Moreover, FRP pultrusion profiles offer immense design flexibility, allowing for customized shapes and sizes that can be tailored to specific applications. This flexibility allows engineers to optimize the profiles' performance in high-vibration scenarios by adjusting the geometry and composition to enhance their dynamic characteristics. In summary, FRP pultrusion profiles are exceptionally suited for high-vibration applications due to their lightweight nature, excellent damping characteristics, resistance to fatigue and corrosion, and design flexibility. These profiles provide a reliable and durable solution that can effectively withstand the challenges posed by vibrations, ensuring safe and efficient operation in such environments.

- Q: The manufacturing process of FRP products?

- 1, hand paste production method; 2, spray forming method; 3, fiber winding process; 4, molding process and molding process; 5, pultrusion method.

- Q: Can FRP pultrusion profiles be used in the production of electrical cabinets?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the production of electrical cabinets. FRP pultrusion profiles provide excellent electrical insulation properties, high strength-to-weight ratio, and resistance to corrosion, making them suitable for use in electrical cabinets where electrical safety and durability are essential.

- Q: Can FRP pultrusion profiles be used in electrical or telecommunications applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in electrical or telecommunications applications. FRP pultrusion profiles are known for their excellent electrical insulating properties, high strength-to-weight ratio, and corrosion resistance. These characteristics make them suitable for various electrical and telecommunications applications. In electrical applications, FRP pultrusion profiles can be used as electrical insulators, cable trays, busbar supports, and electrical enclosures. They provide insulation and protection against electrical shocks and are often chosen as an alternative to traditional materials like metal or wood due to their non-conductive properties. Additionally, FRP pultrusion profiles are lightweight and easy to install, which further adds to their suitability in electrical applications. In telecommunications applications, FRP pultrusion profiles are used for cable management systems, antenna supports, and equipment enclosures. Similar to electrical applications, the non-conductive nature of FRP pultrusion profiles ensures the safety and reliability of the telecommunications infrastructure. The profiles can also be customized to meet specific design requirements, such as incorporating cable routing channels or mounting brackets for equipment. Furthermore, FRP pultrusion profiles offer excellent resistance to harsh environmental conditions, such as moisture, UV radiation, and chemicals. This makes them ideal for outdoor electrical or telecommunications installations, where exposure to these elements is common. Overall, FRP pultrusion profiles have proven to be a reliable and cost-effective choice for electrical and telecommunications applications, providing insulation, strength, durability, and resistance to environmental factors.

- Q: Are FRP pultrusion profiles impact resistant?

- FRP pultrusion profiles are widely recognized for their exceptional impact resistance. By combining reinforcing fibers like glass or carbon with a polymer matrix, they become intrinsically sturdy and long-lasting. The pultrusion process further bolsters their impact resistance by aligning the fibers in the direction of the load, providing optimal strength against impacts. Additionally, these profiles boast a remarkable strength-to-weight ratio, enabling them to withstand heavy impacts without significant damage or deformation. This characteristic makes them ideal for industries like construction, transportation, and infrastructure, where impact resistance is vital. Furthermore, FRP pultrusion profiles exhibit outstanding resistance to corrosion, chemicals, and UV radiation, enhancing their durability and long-term performance. Even in harsh environments, they maintain their impact resistance properties, making them the preferred choice for various sectors. Nonetheless, it is crucial to acknowledge that the impact resistance of FRP pultrusion profiles can vary depending on factors like design, composition, and manufacturing process. To ensure the profiles meet the desired impact resistance requirements for a specific application, it is advisable to consult with the manufacturer or supplier.

- Q: Will the FRP section crack for a long time?

- It will be。Glass steel cracking has the following factors:1, in production, the ingredients are too high, curing reaction is fierce.2, in production, the product is too thick, no sub operation, resulting in thermal cracking.3, the product stiffness is not enough, deformation is too large and cracks.4, the strength of the product is not enough, the use of excessive force due to cracks.5, surface gel will produce cracks due to thermal contraction.

- Q: Are FRP pultrusion profiles resistant to mold and mildew?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are generally resistant to mold and mildew. FRP is a composite material made of a polymer matrix reinforced with fibers, typically glass fibers. Unlike organic materials such as wood or traditional plastics, FRP does not provide a suitable environment for mold and mildew growth. The inherent properties of FRP, such as its non-porous nature and resistance to moisture absorption, make it highly resistant to mold and mildew. Additionally, FRP pultrusion profiles are often manufactured with a smooth and glossy surface, which further inhibits the growth of mold and mildew. Furthermore, FRP is chemically inert, meaning it does not react with most substances. This characteristic makes FRP profiles highly resistant to chemical attacks, including those that may promote the growth of mold and mildew. As a result, FRP pultrusions are commonly used in environments where moisture and humidity are present, such as bathrooms, swimming pools, and outdoor applications. However, it is important to note that while FRP is resistant to mold and mildew, it is not completely immune. In certain extreme conditions, where moisture levels are consistently high and proper maintenance is neglected, mold and mildew growth may still occur. Regular cleaning and maintenance are recommended to ensure the longevity and resistance of FRP pultrusion profiles to mold and mildew.

- Q: Can FRP pultrusion profiles be used in the construction and building materials industry?

- FRP pultrusion profiles are indeed applicable in the construction and building materials sector. These profiles are created by pulling continuous fibers through a resin bath and then into a heated die, which aids in curing the resin and shaping the profile. One of the primary advantages of FRP pultrusion profiles lies in their exceptional strength-to-weight ratio. Despite being lightweight, they possess incredible durability and strength, making them an optimal choice for construction purposes where weight reduction is desired. Moreover, FRP pultrusion profiles exhibit outstanding resistance to corrosion, which proves particularly advantageous in environments with moisture, chemicals, or harsh weather conditions. This corrosion resistance extends the lifespan of building materials, thereby reducing maintenance and replacement expenses. FRP pultrusion profiles can serve a wide array of construction applications, including structural components like beams, columns, and trusses. They are also frequently utilized as reinforcements in concrete structures, offering added strength and durability. Additionally, these profiles find utility in cladding, decking, handrails, ladders, and other non-structural elements within buildings. Furthermore, FRP pultrusion profiles provide design flexibility as they can easily be customized and manufactured to specific shapes, sizes, and properties. This adaptability renders them suitable for diverse construction projects, ranging from small-scale residential buildings to large-scale industrial complexes. In conclusion, FRP pultrusion profiles are highly appropriate for the construction and building materials industry due to their superior strength-to-weight ratio, corrosion resistance, design flexibility, and versatility.

- Q: Can FRP pultrusion profiles be used in oil and gas applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in oil and gas applications. FRP pultrusion profiles are known for their excellent corrosion resistance, high strength-to-weight ratio, and durability, making them suitable for various industries, including oil and gas. In oil and gas applications, FRP pultrusion profiles can be used for a wide range of purposes. They can be employed in the construction of pipelines, offshore platforms, and subsea structures. FRP profiles can also be used in the fabrication of tanks, vessels, and other equipment exposed to corrosive environments. One of the key advantages of FRP pultrusion profiles in oil and gas applications is their resistance to corrosion. Unlike traditional materials like steel, FRP does not rust or corrode when exposed to moisture, chemicals, or saltwater. This corrosion resistance extends the lifespan of the profiles and reduces maintenance costs. Additionally, FRP pultrusion profiles offer high strength and stiffness. They can withstand high pressures, extreme temperatures, and harsh operating conditions typically found in oil and gas environments. Their lightweight nature also makes them easier to handle and install compared to heavier materials like steel. Another benefit of FRP profiles is their non-conductive nature. This property makes them suitable for applications where electrical conductivity needs to be minimized, such as in offshore platforms or in areas with potential electrical hazards. Overall, FRP pultrusion profiles have proven to be a reliable and cost-effective solution for oil and gas applications. Their corrosion resistance, high strength, and lightweight properties make them ideal for various components and structures within the industry.

- Q: Are FRP pultrusion profiles resistant to impact from flying debris?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength and durability. They are generally resistant to impact from flying debris due to their inherent properties. The combination of the reinforcing fibers, typically made of fiberglass, and the polymer matrix provides excellent impact resistance. The specific resistance to impact from flying debris can vary depending on the specific design, thickness, and composition of the FRP pultrusion profiles. However, in most cases, these profiles are designed to withstand impact forces and can effectively resist damage caused by flying debris. Furthermore, FRP pultrusion profiles are often used in applications where impact resistance is crucial, such as in construction, transportation, and infrastructure industries. These profiles have been tested and proven to withstand various impact scenarios, making them a reliable choice for applications where flying debris is a concern. It is important to note that while FRP pultrusion profiles offer good impact resistance, the severity of the impact and the velocity of the flying debris can still affect the level of damage. Therefore, it is advisable to consult with the manufacturer or engineer to ensure the specific FRP profile chosen is suitable for the intended application and potential impact conditions.

Send your message to us

FRP Pultrusion Profiles with Excellent Electromagnetism Property and Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords