FRP Pultrusion Profiles with Excellent Electromagnetism Property and Best Quality on Hot Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

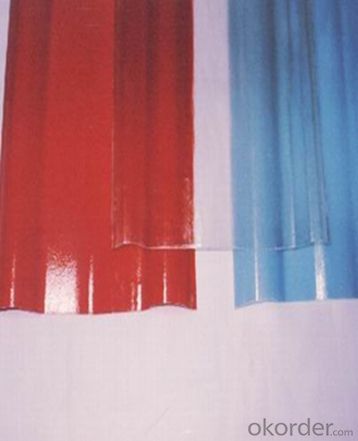

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

PICTURES

- Q: How are FRP pultrusion profiles manufactured?

- FRP pultrusion profiles are manufactured through a continuous process that involves pulling fiber reinforcement material (such as fiberglass) through a resin bath, impregnating it with a thermosetting resin. The saturated fibers are then pulled through a heated die, which shapes the profile to the desired cross-sectional geometry. As the resin cures, the profile hardens and is cut into desired lengths. This efficient and automated process allows for the production of high-strength and lightweight FRP profiles.

- Q: Are FRP pultrusion profiles resistant to chemicals used in semiconductor manufacturing?

- Yes, FRP pultrusion profiles are highly resistant to the chemicals typically used in semiconductor manufacturing. The composite materials used in FRP profiles have excellent chemical resistance, making them ideal for withstanding the corrosive effects of various chemicals used in this industry.

- Q: Are FRP pultrusion profiles resistant to impact from heavy machinery?

- Yes, FRP pultrusion profiles are highly resistant to impact from heavy machinery due to their inherent strength and durability. The strong composite materials used in their construction, such as fiberglass reinforced polymers, provide excellent impact resistance, making them a reliable choice for applications where heavy machinery might be involved.

- Q: Can FRP pultrusion profiles be used in renewable energy projects?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can certainly be used in renewable energy projects. FRP pultrusion profiles offer a wide range of advantages that make them suitable for various applications within the renewable energy sector. Firstly, FRP pultrusion profiles are lightweight yet strong, making them ideal for use in wind turbine blades. The lightweight nature of FRP materials allows for increased efficiency in wind energy generation by reducing the load on the turbine, thus improving overall performance. Additionally, the high strength-to-weight ratio of FRP profiles ensures durability and longevity, even in harsh environmental conditions. Secondly, FRP pultrusion profiles exhibit excellent corrosion resistance, making them suitable for solar panel mounting structures and other components exposed to moisture and outdoor elements. This corrosion resistance ensures that FRP profiles maintain their structural integrity and performance over an extended period of time, reducing the need for frequent maintenance and replacement. Thirdly, FRP pultrusion profiles can be customized to meet specific project requirements, allowing for flexibility in design and functionality. They can be easily molded into complex shapes and sizes, enabling the creation of innovative and efficient solutions for renewable energy projects. Moreover, FRP materials are non-conductive and have excellent electrical insulation properties, making them suitable for use in electrical enclosures and support structures for renewable energy systems such as solar power plants. In conclusion, FRP pultrusion profiles can be effectively utilized in renewable energy projects due to their lightweight, strong, corrosion-resistant, customizable, and electrically-insulating properties. These characteristics make FRP profiles a reliable and sustainable choice for various applications within the renewable energy sector.

- Q: Can FRP pultrusion profiles be used in railway applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in railway applications. FRP pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them ideal for various industries, including railways. In railway applications, FRP pultrusion profiles can be used for a wide range of components such as railway sleepers, bridges, platforms, cable management systems, and even structural support for railway tracks. These profiles offer excellent mechanical properties, including high stiffness and tensile strength, which are crucial for ensuring the safety and integrity of railway infrastructure. Furthermore, FRP pultrusion profiles have low thermal conductivity, making them resistant to extreme temperature variations. This is advantageous in railway applications where exposure to both hot and cold temperatures is common. Another significant advantage of using FRP pultrusion profiles in railway applications is their resistance to corrosion. Unlike traditional materials like steel, FRP does not rust or corrode in the presence of moisture or chemicals. This corrosion resistance minimizes the need for regular maintenance and extends the lifespan of railway components, reducing costs in the long run. Additionally, FRP pultrusion profiles can be easily customized to meet specific design requirements. They can be manufactured in various shapes, sizes, and colors, enabling engineers to create tailored solutions for different railway applications. Overall, the use of FRP pultrusion profiles in railway applications provides numerous benefits, including lightweight design, high strength, corrosion resistance, and customization options. These qualities make FRP an attractive alternative to traditional materials and contribute to the overall safety, efficiency, and longevity of railway infrastructure.

- Q: Are FRP pultrusion profiles resistant to chemicals used in oil refineries?

- Yes, FRP pultrusion profiles are highly resistant to chemicals used in oil refineries. The combination of their fiberglass reinforcement and resin matrix makes them impervious to many corrosive substances, ensuring long-term durability and performance in such harsh environments.

- Q: How do FRP pultrusion profiles perform in high-traffic areas?

- FRP pultrusion profiles are an excellent choice for high-traffic areas due to their exceptional performance characteristics. These profiles are made of reinforced fiberglass and resin, resulting in a highly durable material that can withstand heavy loads and constant foot traffic. One of the key advantages of FRP pultrusion profiles is their high strength-to-weight ratio. This makes them lightweight yet incredibly strong, allowing them to handle heavy loads without sacrificing their structural integrity. Additionally, their non-corrosive nature makes them ideal for areas with high foot traffic, where exposure to moisture, chemicals, and other corrosive elements is common. FRP pultrusion profiles also possess excellent resistance to wear and abrasion. This means that even in high-traffic areas, where constant footfalls and movement can cause conventional materials to deteriorate quickly, FRP profiles remain unaffected, maintaining their original appearance and functionality for an extended period. Furthermore, these profiles are highly resistant to UV radiation, which means they do not degrade or fade when exposed to sunlight. This is particularly important for high-traffic areas that are outdoors or have large windows, as the profiles will maintain their strength and aesthetics even under constant exposure to the sun. In terms of maintenance, FRP pultrusion profiles require minimal upkeep. They do not require regular painting or sealing, as their color and finish are built into the material itself. This significantly reduces maintenance costs and efforts, making them a cost-effective choice for high-traffic areas. Overall, FRP pultrusion profiles are an excellent option for high-traffic areas due to their exceptional strength, durability, resistance to wear and abrasion, non-corrosive properties, UV resistance, and low maintenance requirements. Their ability to withstand heavy loads and constant foot traffic ensures their long-lasting performance, making them a reliable choice for any high-traffic environment.

- Q: Can FRP pultrusion profiles be used in the automotive manufacturing industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the automotive manufacturing industry. FRP pultrusion profiles offer several advantages that make them suitable for automotive applications. Firstly, FRP profiles are lightweight, which helps in reducing the overall weight of the vehicle. This is crucial for improving fuel efficiency and reducing emissions. The lighter weight of FRP profiles also allows for better handling and improved performance. Secondly, FRP profiles possess excellent mechanical properties such as high strength and stiffness. This makes them suitable for use in structural components of vehicles, such as chassis, body panels, and frames. FRP profiles can withstand heavy loads and offer good impact resistance, ensuring the safety of the vehicle and its occupants. Additionally, FRP profiles exhibit excellent corrosion resistance, which is particularly beneficial for automotive applications. Unlike traditional materials like steel, FRP profiles are not susceptible to rust or corrosion, making them ideal for use in various automotive environments, including exposure to moisture, chemicals, and salt. Furthermore, FRP pultrusion profiles can be tailored to meet specific design requirements, allowing for flexibility in manufacturing. They can be produced in various shapes and sizes, offering versatility in designing complex components. This flexibility in design also allows for customization and optimization of vehicle performance. Lastly, FRP profiles offer good thermal and electrical insulation properties. This makes them suitable for applications where electrical conductivity needs to be minimized or thermal insulation is required. Overall, the lightweight, high strength, corrosion resistance, design flexibility, and insulation properties of FRP pultrusion profiles make them well-suited for use in the automotive manufacturing industry. They can contribute to the development of more efficient, safe, and durable vehicles.

- Q: What are the typical lifespan of FRP pultrusion profiles?

- The typical lifespan of FRP pultrusion profiles can vary depending on various factors such as the specific application, environmental conditions, and maintenance practices. However, on average, FRP pultrusion profiles can have a lifespan ranging from 20 to 50 years.

- Q: Are FRP pultrusion profiles resistant to impact?

- FRP pultrusion profiles exhibit a general resistance to impact. The amalgamation of robust fibers and the polymer matrix employed during manufacturing renders FRP profiles exceptionally enduring, enabling them to endure substantial impacts without fracturing or shattering. Furthermore, the pultrusion process guarantees the uniform dispersion of fibers within the profile, thereby bolstering its capacity to resist impact. Consequently, FRP pultrusion profiles are ideally suited for impact-prone applications, including construction, transportation, and infrastructure ventures.

Send your message to us

FRP Pultrusion Profiles with Excellent Electromagnetism Property and Best Quality on Hot Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords