FRP Pultrusion Profiles Pultruded Grating Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 0 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of FRP Pultruded Grating

FRP grating is made by pultrusion FRP profiles have been assembled, with light weight, high strength, corrosion protection, prevent slippery, aging resistance, impact resistance, easy opening, cutting and not scattered features, widely used in petroleum, chemical industry, electric power, electroplating, etc work platforms, equipment platforms, stair tread, trench cover, pier walkways and so on, is the corrosion environment is the ideal substitute of traditional metal grille.

Main Features of FRP Pultruded Grating

Anti-corrosion and anti-rust

Light weight and high strength

Anti-flammable

Anti-fatigue

Safe and anti-slippery

Anti-ageing

Easy of maintenance

Excellent electromagnetism property

Good economic benefit

Specifications of FRP Pultruded Grating

The standard space between two crossbars is 6 inch or 12 inch.

| Thickness(mm) | Bar width (mm) | Open space(mm) | Open rate (%) | Approx weight(kg/m²) |

| 25.4 | 15.2 | 22.8 | 60 | 13.2 |

| 25.4 | 15.2 | 15.2 | 50 | 15.9 |

| 25.4 | 15.2 | 10.1 | 40 | 18.5 |

| 25.4 | 40 | 10.8 | 21 | 14.5 |

| 38.1 | 15.2 | 22.8 | 60 | 15.8 |

| 38.1 | 15.2 | 15.2 | 50 | 19.1 |

| 38.1 | 15.2 | 10.1 | 40 | 22.4 |

| 50.8 | 25.4 | 25.4 | 50 | 16.6 |

| 50.8 | 25.4 | 12.7 | 33 | 21.1 |

Applications of FRP Pultruded Grating

operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

Choice For FRP Pultruded Grating

Resin:GP resin, ISO resin, VE resin, Phenolic resin

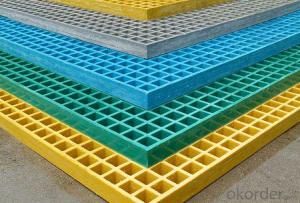

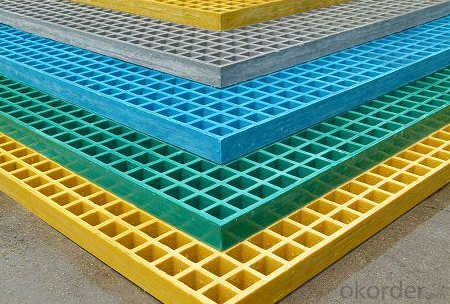

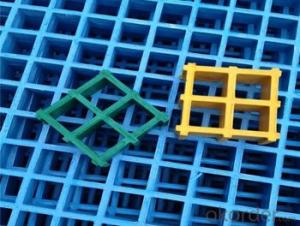

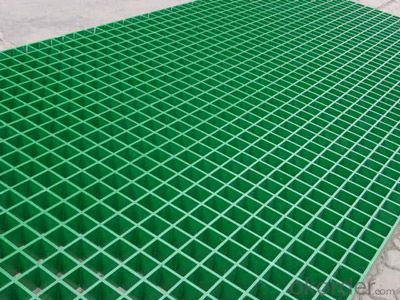

Color choice: Yellow gray custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

IMages of FRP Pultruded Grating

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

- Q: Can FRP pultrusion profiles be used in the renewable energy and solar power industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the renewable energy and solar power industry. These profiles offer several advantages such as high strength, durability, corrosion resistance, and lightweight properties, making them suitable for various applications in the industry. FRP pultrusion profiles can be used for structural components, support structures, mounting systems, and other applications in solar panels, wind turbines, wave energy devices, and other renewable energy systems.

- Q: How do FRP pultrusion profiles compare to traditional materials, such as steel or aluminum?

- FRP pultrusion profiles offer several advantages compared to traditional materials like steel or aluminum. Firstly, FRP profiles are significantly lighter in weight, making them easier to handle and transport. This characteristic is especially beneficial in applications where weight reduction is crucial, such as in aerospace or automotive industries. Moreover, FRP pultrusion profiles are highly corrosion resistant, unlike steel which is prone to rusting and aluminum which can corrode in certain environments. This corrosion resistance makes FRP profiles ideal for applications in harsh or corrosive environments, such as chemical plants or coastal areas. Another advantage of FRP pultrusion profiles is their excellent strength-to-weight ratio. Despite being lightweight, FRP profiles exhibit high strength and stiffness, often surpassing steel and aluminum. This strength allows for the design of structurally efficient components, reducing material and installation costs. Furthermore, FRP profiles are electrically non-conductive, offering inherent insulation properties. This feature makes them suitable for applications where electrical conductivity is undesirable, such as electrical cabinets or offshore platforms. In terms of thermal conductivity, FRP pultrusion profiles have low thermal conductivity compared to metals. This characteristic improves insulation and reduces heat transfer, making them suitable for applications requiring temperature control or insulation, such as refrigeration or thermal insulation systems. Lastly, FRP pultrusion profiles are highly customizable. They can be easily molded into complex shapes and sizes, allowing for design flexibility and meeting specific project requirements. This versatility makes FRP profiles suitable for a wide range of applications, including construction, infrastructure, and industrial sectors. Overall, FRP pultrusion profiles offer numerous advantages over traditional materials like steel or aluminum, including lighter weight, corrosion resistance, high strength-to-weight ratio, electrical insulation, low thermal conductivity, and design flexibility. These benefits make FRP profiles a preferred choice in various industries, providing cost-effective and reliable solutions.

- Q: Are FRP pultrusion profiles resistant to fading or discoloration?

- Yes, FRP pultrusion profiles are highly resistant to fading or discoloration. The profiles are made with high-quality resins and UV stabilizers that provide excellent protection against sunlight, chemicals, and environmental factors, ensuring long-term color stability and preventing any significant fading or discoloration.

- Q: What are the main uses of pultruded glass fiber reinforced plastic extrusions?

- Construction of shopping malls, in the construction of shopping malls, pull glass fiber reinforced plastic has entered the traditional data shopping malls, such as: doors and windows, concrete templates, scaffolding, staircase handrails, house stalls, wall panels, tendons, decoration materials. It is worth noting that the materials and decoration materials will have a lot of room for improvement.

- Q: Are FRP pultrusion profiles UV resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are typically UV resistant. This is because they are manufactured using a combination of polymer resin and reinforced fibers such as fiberglass. These materials have inherent UV resistant properties, making FRP pultrusion profiles resistant to damage caused by prolonged exposure to sunlight and ultraviolet radiation. UV resistance is a crucial characteristic for outdoor applications where the profiles will be exposed to sunlight, such as in construction, infrastructure, and marine industries. However, it is important to note that the level of UV resistance may vary depending on the specific resin and fiber composition used in the manufacturing process. Therefore, it is recommended to consult the manufacturer or supplier for specific information on the UV resistance of FRP pultrusion profiles for a particular application.

- Q: Can FRP pultrusion profiles be used in the construction industry?

- Indeed, the construction industry can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles offer numerous benefits that make them appropriate for diverse construction applications. To begin with, FRP pultrusion profiles possess exceptional strength while remaining lightweight. Consequently, they are an excellent choice for construction projects as they provide a high strength-to-weight ratio. This reduces the overall weight of the structure while preserving its structural integrity. This advantage is particularly valuable for applications like bridges, walkways, and platforms. Furthermore, FRP pultrusion profiles exhibit a high level of resistance to corrosion. Unlike conventional construction materials such as steel or wood, FRP does not rust, rot, or corrode when exposed to harsh environmental conditions, chemicals, or moisture. Consequently, FRP profiles are ideal for outdoor or marine applications where corrosion can be a concern, such as seawalls, docks, or offshore structures. In addition, FRP pultrusion profiles possess excellent electrical and thermal insulation properties. This makes them suitable for applications where minimizing electrical conductivity is necessary, such as electrical enclosures or cable trays. Moreover, FRP profiles have low thermal conductivity, which enhances energy efficiency in buildings by reducing heat transfer. Furthermore, FRP pultrusion profiles are highly durable and require minimal maintenance. They boast a long service life and do not necessitate regular painting, sealing, or treatment like traditional materials. Consequently, significant cost savings can be achieved throughout the life cycle of a construction project. Lastly, FRP pultrusion profiles can be customized to meet specific strength, stiffness, and dimensional requirements. They can be produced in various shapes, sizes, and colors, allowing for flexibility in design. This versatility renders FRP profiles suitable for a wide range of construction applications, including beams, columns, gratings, handrails, and structural components. To summarize, FRP pultrusion profiles are a viable choice for the construction industry due to their lightweight nature, high strength, corrosion resistance, electrical and thermal insulation properties, durability, low maintenance requirements, and design flexibility.

- Q: Are FRP pultrusion profiles resistant to hydraulic oils?

- Yes, FRP pultrusion profiles are generally resistant to hydraulic oils. The combination of fiberglass reinforcement and resin matrix used in pultrusion manufacturing makes these profiles highly resistant to various chemicals, including hydraulic oils. However, it is recommended to consult the specific resin manufacturer or supplier for detailed information on the compatibility of their FRP pultrusion profiles with different types of hydraulic oils.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical packaging?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in pharmaceutical packaging. FRP pultrusion profiles are made of a combination of reinforced fibers and a polymer resin matrix, which provides them with excellent chemical resistance properties. The polymer resin used in FRP profiles is typically selected to be compatible with a wide range of chemicals, including those commonly used in pharmaceutical packaging. FRP profiles have been extensively used in various industries, including pharmaceuticals, due to their high chemical resistance. They are capable of withstanding exposure to a wide range of chemicals, such as acids, bases, solvents, and other aggressive substances commonly found in pharmaceutical packaging processes. This resistance helps protect the integrity of the packaging and ensures that there is no contamination or degradation of the pharmaceutical products. Additionally, FRP pultrusion profiles are also resistant to corrosion, which is another advantage in the pharmaceutical industry where aggressive chemicals may be present. This resistance to corrosion further enhances the durability and longevity of the FRP profiles, making them a reliable choice for pharmaceutical packaging applications. However, it is important to note that the specific chemical resistance of FRP pultrusion profiles may vary depending on the type and concentration of the chemicals being used. Therefore, it is recommended to consult the manufacturer or supplier of the FRP profiles to ensure their compatibility with the specific chemicals used in pharmaceutical packaging.

- Q: Can FRP pultrusion profiles be used in the construction of stadium seating?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of stadium seating. FRP pultrusion profiles have several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are lightweight yet strong, which is ideal for stadium seating where a large number of seats need to be installed. The lightweight nature of FRP profiles makes them easier to handle and install, reducing the time and effort required for construction. Secondly, FRP pultrusion profiles are highly durable and resistant to corrosion, making them suitable for outdoor applications like stadium seating. They are not prone to rusting, rotting, or degradation from exposure to moisture, UV rays, or chemicals commonly found in stadiums. Additionally, FRP pultrusion profiles are non-conductive, providing an added safety benefit, especially in areas where electrical wiring may be present. This reduces the risk of electric shocks or accidents that can occur with conductive materials. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in designing stadium seating layouts. They can be manufactured in various shapes, sizes, and colors to match the aesthetic and functional requirements of the stadium. Lastly, FRP pultrusion profiles have a long service life with low maintenance requirements, reducing the overall cost of ownership for stadium seating. This makes them a cost-effective choice in the long run. In conclusion, FRP pultrusion profiles are an excellent choice for the construction of stadium seating due to their lightweight, durable, non-conductive, customizable, and cost-effective nature.

- Q: Are FRP pultrusion profiles resistant to humidity or moisture?

- Yes, FRP pultrusion profiles are highly resistant to humidity or moisture due to their non-porous nature and the use of corrosion-resistant materials.

Send your message to us

FRP Pultrusion Profiles Pultruded Grating Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 0 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords