FRP Pultrusion Profiles for Anti-Fatigue FRP Pultruded Grating with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

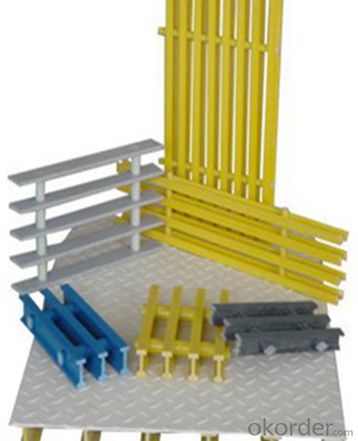

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

Q1.What's your sample policy?

A:We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q2.Can you produce according to the samples?

A: Yes, we can produce or modify the products according to your request.

Q3.How do you deliver the goods to my country?

A:We can provide international express, such as DHL, EMS, UPS, FedEx, etc. We select air freight and sea freight upon your requests. Quotations if without mentioning the shipping costs are shipping fee excluded.

Q4.How much does it cost to ship to my country?

A:When you goanna to place an order, please contact us, because different country has different freight.

Q5.How to get the catalogue?

A:please contact us and tell us what you are looking for.

We will try our best to meet customers' demands. Welcome you come here to visit us. We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

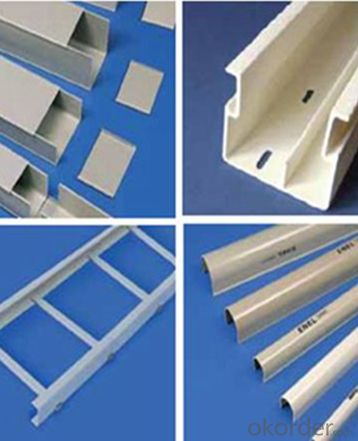

PICTURES

- Q: Can FRP pultrusion profiles be used in architectural or decorative applications?

- Yes, FRP pultrusion profiles can definitely be used in architectural or decorative applications. FRP, which stands for Fiber Reinforced Polymer, is a composite material that combines strong fibers, such as glass or carbon, with a polymer resin matrix. This combination creates a lightweight, durable, and corrosion-resistant material that is ideal for various applications, including architecture and decoration. FRP pultrusion profiles can be manufactured in a wide range of shapes and sizes, making them highly versatile for architectural and decorative purposes. These profiles can be used to create aesthetically pleasing structures, such as columns, beams, and facades, that enhance the visual appeal of buildings. Additionally, FRP pultrusion profiles can be fabricated to mimic the appearance of other materials, such as wood or metal, allowing for the creation of decorative elements that blend seamlessly with the overall design. Furthermore, FRP pultrusion profiles offer several advantages over traditional materials commonly used in architecture and decoration. They are lightweight, which makes them easier to handle and install, reducing labor costs. They are also highly resistant to corrosion, weathering, and UV radiation, ensuring long-lasting performance in outdoor applications. Additionally, FRP profiles can be customized to meet specific design requirements, including color, texture, and surface finish, providing endless possibilities for creative expression. In summary, FRP pultrusion profiles are a viable option for architectural and decorative applications. Their lightweight, durable, and customizable nature makes them suitable for a wide range of design needs, while their corrosion resistance ensures longevity and low maintenance. Whether it's for structural support or decorative embellishments, FRP pultrusion profiles offer an excellent choice for enhancing the aesthetics and functionality of architectural and decorative projects.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of antenna masts?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of antenna masts. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and excellent electrical insulation properties. These characteristics make them ideal for antenna mast construction, as they can withstand various environmental conditions and provide reliable support for antennas.

- Q: What are the insulation properties of FRP pultrusion profiles?

- FRP pultrusion profiles have excellent insulation properties due to the inherent nature of the materials used in their construction. The fiberglass reinforcement in FRP profiles provides high thermal resistance, making them effective in retaining heat and preventing its transfer. Additionally, FRP profiles have low thermal conductivity, meaning they do not readily conduct heat or cold, further enhancing their insulation capabilities. Overall, FRP pultrusion profiles offer superior insulation properties, making them ideal for applications that require temperature control or energy efficiency.

- Q: Are FRP pultrusion profiles resistant to hydrochloric acid?

- FRP pultrusion profiles exhibit a general resistance to hydrochloric acid. The corrosion resistance of FRP materials varies based on the specific resin and fiber used during manufacturing. Nevertheless, most FRP pultrusion profiles are designed to endure exposure to a wide array of chemicals, including hydrochloric acid. The corrosion resistance of FRP is attributed to the chemical inertness of the resin matrix, typically composed of polyester, vinyl ester, or epoxy. These resins form a protective barrier against chemical attack, allowing FRP profiles to maintain their structural integrity even in harsh surroundings. However, the level of resistance may fluctuate depending on the concentration and temperature of the hydrochloric acid. In instances of high concentration or elevated temperatures, the resistance may diminish. It is always recommended to refer to the manufacturer's specifications or seek expert advice to ensure the suitability of FRP pultrusion profiles for specific acid concentrations and temperature ranges. In conclusion, FRP pultrusion profiles are renowned for their exceptional chemical resistance and are frequently selected for applications involving exposure to acids or corrosive environments.

- Q: Can FRP pultrusion profiles be used in walkway systems?

- Walkway systems can indeed utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles are renowned for their impressive strength-to-weight ratio, resistance to corrosion, and durability, which makes them an excellent option for various applications, including walkway systems. Due to the lightweight nature of FRP pultrusion profiles, they are easy to handle and install, which ultimately reduces construction time and cost. Moreover, their corrosion resistance ensures that they can endure harsh environmental conditions, such as exposure to moisture, chemicals, and UV radiation, without deteriorating or requiring frequent maintenance. FRP pultrusion profiles can be tailored to meet specific design requirements, enabling the creation of walkway systems with diverse shapes, sizes, and load-bearing capacities. These profiles can be manufactured with anti-slip surfaces or integrated with other safety features to enhance traction and prevent accidents on the walkways. Furthermore, FRP pultrusion profiles possess excellent electrical insulation properties, making them suitable for walkway systems in areas where minimizing electrical conductivity is necessary, such as power plants or electrical substations. All in all, the distinctive properties of FRP pultrusion profiles make them a dependable and versatile material choice for walkway systems. They offer long-lasting performance, low maintenance requirements, and enhanced safety.

- Q: Are FRP pultrusion profiles resistant to chemicals used in chemical plants?

- FRP pultrusion profiles exhibit a general resistance to a wide range of chemicals employed in chemical plants. Their exceptional chemical resistance properties make FRP materials appropriate for diverse industrial applications, including chemical plants. The pultruded FRP profiles are manufactured by saturating reinforcing fibers with a thermosetting resin, such as polyester, vinylester, or epoxy. The selection of these resins is based on their resistance to various chemicals and can be tailored to meet specific requirements. FRP pultrusion profiles have demonstrated their ability to withstand aggressive chemicals, including acids, bases, solvents, and corrosive gases. Most common chemicals found in chemical plants, such as sulfuric acid, hydrochloric acid, nitric acid, and sodium hydroxide, typically do not affect them. Nevertheless, it is important to consider that the resistance of FRP pultrusion profiles may vary depending on the specific resin system, as well as the concentration and temperature of the chemicals involved. To ensure the suitability of the chosen FRP profiles for the chemical environment in a chemical plant, it is always advisable to consult with the manufacturer or supplier.

- Q: Are FRP pultrusion profiles resistant to moisture absorption?

- FRP pultrusion profiles possess remarkable resistance to moisture absorption, primarily due to the composition of the materials used in their construction. These profiles typically consist of a combination of fiberglass and resin, wherein fiberglass is naturally non-porous and impervious to moisture, while the resin is specifically designed to repel moisture. The moisture resistance of FRP profiles is further enhanced by the pultrusion manufacturing process. This process involves pulling the fiberglass and resin through a heated die, ensuring thorough impregnation of the fibers with resin and creating a dense and solid structure. Consequently, the resulting product exhibits exceptional resistance to water penetration and moisture absorption. Additionally, the moisture resistance of FRP pultrusion profiles can be augmented through the application of protective coatings or surface treatments, such as gel coats or UV-resistant finishes. These coatings provide an extra layer of defense against moisture ingress. The superior moisture resistance of FRP pultrusion profiles makes them an ideal choice for applications that involve exposure to water or high humidity, such as marine environments, wastewater treatment plants, or outdoor structures. By preventing issues like rot, rust, or degradation commonly associated with materials like wood or metal, these profiles offer a reliable and durable solution that can endure moisture exposure without compromising their structural integrity or performance.

- Q: Are FRP pultrusion profiles resistant to chemical spills or leaks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemical spills or leaks. The combination of the fiberglass reinforcement and the polymer matrix used in FRP pultrusion provides excellent resistance to a wide range of chemicals, acids, and corrosive substances. This makes FRP pultrusion profiles a suitable choice for applications where chemical resistance is crucial, such as in chemical processing plants, wastewater treatment facilities, and storage tanks.

- Q: Are FRP pultrusion profiles resistant to impact from flying debris?

- Yes, FRP pultrusion profiles are highly resistant to impact from flying debris. Thanks to their reinforced fiberglass construction, these profiles have exceptional strength and durability, making them capable of withstanding significant impact forces without incurring damage.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food processing?

- Yes, FRP pultrusion profiles are generally resistant to chemicals used in food processing. Fiberglass reinforced plastic (FRP) is known for its excellent chemical resistance, making it suitable for various industrial applications, including the food processing industry. FRP pultrusion profiles are composed of a combination of resins and fiberglass reinforcements, which provide them with inherent resistance to a wide range of chemicals. FRP pultrusion profiles are typically resistant to acids, alkalis, solvents, and many other chemicals commonly found in food processing environments. This resistance ensures that the profiles will not corrode, degrade, or react with the chemicals, preserving their structural integrity over time. This makes FRP pultrusion profiles a reliable choice for equipment, structures, and components used in food processing facilities. However, it is important to note that the specific chemical resistance of FRP pultrusion profiles can vary depending on the resin system used in their manufacturing. Different resins offer different levels of resistance to specific chemicals. Therefore, it is crucial to select the appropriate resin formulation that matches the specific chemical environment in the food processing industry. To ensure the compatibility of FRP pultrusion profiles with the chemicals used in food processing, it is advisable to consult with the manufacturer or supplier. They can provide detailed information on the chemical resistance properties of their FRP profiles and assist in selecting the most suitable materials for the specific application. Additionally, proper maintenance and regular cleaning practices should be implemented to ensure the longevity and continued chemical resistance of FRP pultrusion profiles in food processing environments.

Send your message to us

FRP Pultrusion Profiles for Anti-Fatigue FRP Pultruded Grating with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords