FRP Pultrusion Profiles - Pultruded Gratings with Anti-Fatigue and Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 14 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

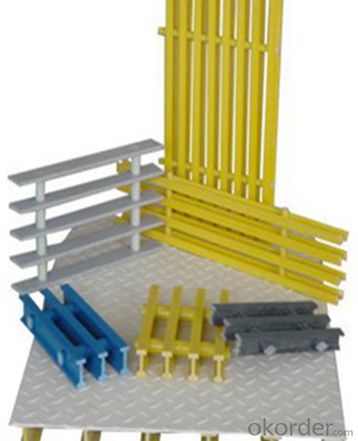

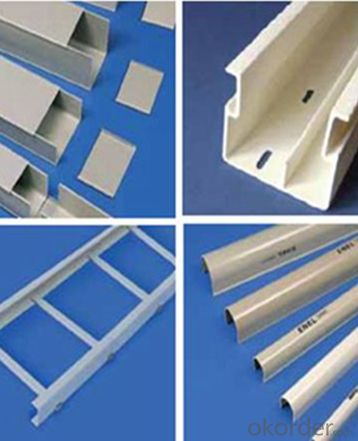

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

Q1.What's your sample policy?

A:We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q2.Can you produce according to the samples?

A: Yes, we can produce or modify the products according to your request.

Q3.How do you deliver the goods to my country?

A:We can provide international express, such as DHL, EMS, UPS, FedEx, etc. We select air freight and sea freight upon your requests. Quotations if without mentioning the shipping costs are shipping fee excluded.

Q4.How much does it cost to ship to my country?

A:When you goanna to place an order, please contact us, because different country has different freight.

Q5.How to get the catalogue?

A:please contact us and tell us what you are looking for.

We will try our best to meet customers' demands. Welcome you come here to visit us. We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

PICTURES

- Q: What are the typical applications for FRP pultrusion profiles?

- Some typical applications for FRP pultrusion profiles include structural components in the construction industry, such as beams, columns, and reinforcements. They are also used in the transportation industry for manufacturing lightweight and corrosion-resistant parts for vehicles and ships. Additionally, FRP pultrusion profiles find applications in electrical and power generation industries, as well as in the manufacturing of sports equipment and infrastructure.

- Q: Can FRP pultrusion profiles be used in the automotive industry?

- Certainly, the automotive industry can certainly make use of FRP (Fiber Reinforced Plastic) pultrusion profiles. These profiles possess several advantages that render them appropriate for automotive purposes. To begin with, FRP pultrusion profiles are lightweight, a critical factor in the automotive industry as it contributes to better fuel efficiency and reduced vehicle weight. Vehicles that are lighter consume less energy and emit fewer pollutants, making them more eco-friendly. Moreover, FRP pultrusion profiles exhibit a remarkable strength-to-weight ratio, enabling them to provide high strength and stiffness while remaining lightweight. This characteristic makes them ideal for structural components in automobiles, such as chassis, body panels, and support structures. In addition, FRP pultrusion profiles display exceptional corrosion resistance, a considerable advantage in automotive applications. Vehicles are frequently exposed to harsh environmental conditions, including moisture, salt, and chemicals. The corrosion resistance of FRP ensures the durability and longevity of automotive components, even in challenging environments. Furthermore, FRP pultrusion profiles possess impressive impact resistance, a crucial aspect of automotive safety. They can effectively absorb and dissipate energy during impacts, reducing the risk of injury in the event of accidents. Moreover, FRP pultrusion profiles can be customized and engineered to meet specific design requirements, allowing for versatility in automotive applications. They can be tailored to possess specific mechanical properties, shapes, and sizes, making them suitable for various automotive components. Overall, the combination of lightweight construction, high strength, corrosion resistance, impact resistance, and customization options make FRP pultrusion profiles an excellent choice for the automotive industry. They offer numerous benefits, including improved fuel efficiency, enhanced safety, and extended component life, making them a viable alternative to traditional materials in automotive applications.

- Q: Can FRP pultrusion profiles be used in chemical storage tanks?

- Yes, FRP pultrusion profiles can be used in chemical storage tanks. FRP (Fiber Reinforced Plastic) materials are known for their excellent corrosion resistance and durability, making them an ideal choice for storing various chemicals. The pultrusion process further enhances the strength and structural integrity of the profiles, making them suitable for demanding applications like chemical storage tanks.

- Q: Can FRP pultrusion profiles be used in the construction of industrial flooring?

- Indeed, the utilization of FRP (Fiber Reinforced Polymer) pultrusion profiles is viable in the construction of industrial flooring. These profiles are comprised of a composite material, combining robust fibers (usually glass or carbon) with a polymer resin. This amalgamation of materials imparts exceptional strength, durability, and resistance to corrosion, rendering FRP profiles highly suitable for industrial flooring applications. The primary benefit of FRP pultrusion profiles lies in their remarkable strength-to-weight ratio. Consequently, they are lighter and more manageable compared to conventional materials like steel or concrete. Moreover, FRP profiles possess non-conductive and non-magnetic properties, offering advantages in specific industrial environments. FRP pultrusion profiles also exhibit high resistance to various chemicals, moisture, and UV radiation, making them an ideal choice for harsh and corrosive settings. Unlike steel, they do not rust or corrode, nor are they affected by moisture or rot like wood. As a result, they ensure long-lasting performance and necessitate minimal maintenance. Additionally, FRP profiles can be customized and manufactured in diverse shapes, sizes, and load-bearing capacities to meet specific industrial flooring requirements. They can be designed to withstand heavy loads, impact, vibration, and other dynamic forces commonly encountered in industrial settings. In conclusion, FRP pultrusion profiles offer numerous advantages that make them well-suited for the construction of industrial flooring. Their high strength, durability, corrosion resistance, and customizable nature make them a dependable and cost-effective choice for industrial flooring applications.

- Q: Can FRP pultrusion profiles be used in telecommunications towers?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in telecommunications towers. FRP materials offer several advantages for such applications, including high strength-to-weight ratio, corrosion resistance, and electrical non-conductivity. These properties make FRP pultrusion profiles suitable for use in telecommunications towers, providing structural support while offering durability and longevity.

- Q: How do FRP pultrusion profiles perform in high-traffic areas?

- FRP pultrusion profiles are an excellent choice for high-traffic areas due to their exceptional performance characteristics. These profiles are made of reinforced fiberglass and resin, resulting in a highly durable material that can withstand heavy loads and constant foot traffic. One of the key advantages of FRP pultrusion profiles is their high strength-to-weight ratio. This makes them lightweight yet incredibly strong, allowing them to handle heavy loads without sacrificing their structural integrity. Additionally, their non-corrosive nature makes them ideal for areas with high foot traffic, where exposure to moisture, chemicals, and other corrosive elements is common. FRP pultrusion profiles also possess excellent resistance to wear and abrasion. This means that even in high-traffic areas, where constant footfalls and movement can cause conventional materials to deteriorate quickly, FRP profiles remain unaffected, maintaining their original appearance and functionality for an extended period. Furthermore, these profiles are highly resistant to UV radiation, which means they do not degrade or fade when exposed to sunlight. This is particularly important for high-traffic areas that are outdoors or have large windows, as the profiles will maintain their strength and aesthetics even under constant exposure to the sun. In terms of maintenance, FRP pultrusion profiles require minimal upkeep. They do not require regular painting or sealing, as their color and finish are built into the material itself. This significantly reduces maintenance costs and efforts, making them a cost-effective choice for high-traffic areas. Overall, FRP pultrusion profiles are an excellent option for high-traffic areas due to their exceptional strength, durability, resistance to wear and abrasion, non-corrosive properties, UV resistance, and low maintenance requirements. Their ability to withstand heavy loads and constant foot traffic ensures their long-lasting performance, making them a reliable choice for any high-traffic environment.

- Q: Can FRP pultrusion profiles be used in automotive applications?

- Yes, FRP pultrusion profiles can be used in automotive applications. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. Additionally, FRP pultrusion profiles can withstand harsh environmental conditions, making them suitable for various automotive components, including body panels, structural supports, and interior parts.

- Q: How do FRP pultrusion profiles perform in extreme cold temperatures?

- Due to the properties of the materials used, FRP pultrusion profiles perform exceptionally well in extremely cold temperatures. These profiles, made of FRP composites, are known for their excellent thermal insulation properties, which help maintain their structural integrity even in low temperatures. One major advantage of FRP pultrusion profiles in cold environments is their ability to resist freezing and thawing cycles. Unlike other materials, FRP does not absorb water, thus preventing expansion or contraction with temperature changes. This eliminates the risk of cracking or damage that can occur when moisture freezes and expands within traditional materials like metal or concrete. Moreover, FRP pultrusion profiles have a low coefficient of thermal expansion, meaning they do not significantly expand or contract with temperature fluctuations. This stability allows them to maintain their shape and structural integrity in extreme cold, reducing the chances of deformation or failure. Aside from their thermal properties, FRP pultrusion profiles also exhibit high strength and durability, making them suitable for various applications in construction, infrastructure, and transportation, even in harsh cold environments. They are resistant to corrosion, chemicals, and UV radiation, further enhancing their performance and longevity in extreme conditions. In conclusion, FRP pultrusion profiles are an excellent choice for applications requiring reliable performance in extreme cold temperatures. With their thermal insulation properties, resistance to freezing and thawing cycles, low coefficient of thermal expansion, and overall strength and durability, they are well-suited for various industries and environments, ensuring their continued performance even in the harshest cold conditions.

- Q: Are FRP pultrusion profiles resistant to moisture absorption?

- Yes, FRP pultrusion profiles are highly resistant to moisture absorption. The inherent properties of the fiberglass and resin used in pultrusion manufacturing make the profiles highly durable and impervious to moisture, ensuring long-term performance and minimal structural damage.

- Q: Can FRP pultrusion profiles be used in the renewable energy and solar power industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the renewable energy and solar power industry. FRP pultrusion profiles possess several key characteristics that make them ideal for such applications. Firstly, FRP pultrusion profiles have high strength-to-weight ratio, meaning they are lightweight yet strong, which is crucial in the renewable energy sector where materials need to withstand various environmental conditions while being cost-effective. Secondly, FRP pultrusion profiles offer excellent corrosion resistance, ensuring durability and longevity in outdoor and potentially corrosive environments, such as solar power plants or wind farms. Additionally, these profiles have excellent electrical insulation properties, making them suitable for electrical applications commonly found in the renewable energy industry. Moreover, FRP pultrusion profiles can be easily customized into various shapes and sizes, enabling the design and engineering of complex structures required for solar power installations or wind turbine blades. Furthermore, FRP materials are non-conductive and non-magnetic, making them safe for use in electrical and magnetic fields associated with renewable energy systems. Overall, FRP pultrusion profiles offer a combination of strength, durability, lightweight, corrosion resistance, and electrical insulation properties that make them highly suitable for use in the renewable energy and solar power industry.

Send your message to us

FRP Pultrusion Profiles - Pultruded Gratings with Anti-Fatigue and Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 14 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords