FRP Pultrusion Profiles - Pultruded Gratings with Anti-Fatigue and Best Quality in Different Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

Q1.What's your sample policy?

A:We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q2.Can you produce according to the samples?

A: Yes, we can produce or modify the products according to your request.

Q3.How do you deliver the goods to my country?

A:We can provide international express, such as DHL, EMS, UPS, FedEx, etc. We select air freight and sea freight upon your requests. Quotations if without mentioning the shipping costs are shipping fee excluded.

Q4.How much does it cost to ship to my country?

A:When you goanna to place an order, please contact us, because different country has different freight.

Q5.How to get the catalogue?

A:please contact us and tell us what you are looking for.

We will try our best to meet customers' demands. Welcome you come here to visit us. We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

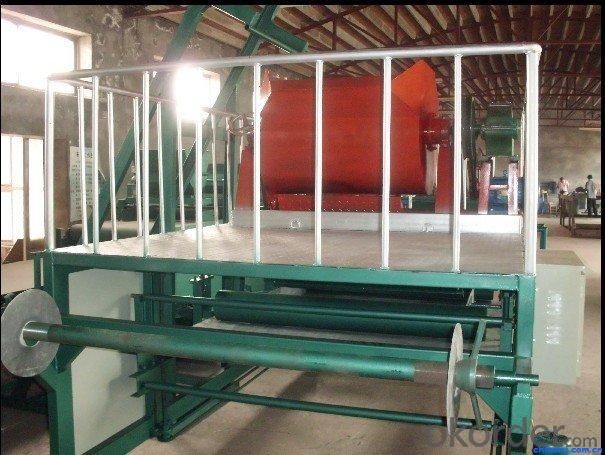

PICTURES

- Q: What is the lifespan of FRP pultrusion profiles?

- The lifespan of FRP (Fiber Reinforced Polymer) pultrusion profiles can vary depending on several factors. Generally, FRP pultrusion profiles have a long lifespan and are known for their durability and longevity. One key factor that influences the lifespan of FRP pultrusion profiles is the quality of the materials used in their construction. High-quality FRP materials, such as those made with premium resins and high-strength fibers, tend to have a longer lifespan compared to lower-quality materials. Additionally, the environmental conditions in which the FRP pultrusion profiles are installed can impact their lifespan. Exposure to extreme temperatures, moisture, UV radiation, chemicals, and mechanical stresses can all affect the performance and lifespan of FRP profiles. Therefore, proper installation and maintenance are crucial to ensuring their longevity. When properly designed, manufactured, and installed, FRP pultrusion profiles can have a lifespan ranging from 25 to 50 years or even longer. However, it is important to note that this estimate can vary depending on the specific application, the level of exposure to harsh conditions, and the overall care and maintenance of the profiles over time. Regular inspections, cleaning, and repairs, if necessary, can help extend the lifespan of FRP pultrusion profiles. Consultation with manufacturers or industry experts can provide more specific information on the expected lifespan of FRP profiles for a particular application or environment.

- Q: Can FRP pultrusion profiles be used in the construction of wind turbine blades?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of wind turbine blades. FRP pultrusion profiles offer several advantages that make them suitable for wind turbine blade construction. Firstly, FRP pultrusion profiles are lightweight yet strong, which is an important characteristic in wind turbine blades as they need to be able to withstand the aerodynamic forces exerted by the wind. The high strength-to-weight ratio of FRP pultrusion profiles allows for the construction of longer and more efficient blades. Additionally, FRP pultrusion profiles have excellent corrosion resistance properties, which is crucial for wind turbines exposed to harsh weather conditions. Unlike traditional materials like steel, FRP does not corrode, ensuring a longer service life for the wind turbine blades. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements. This flexibility allows for the optimization of blade performance by tailoring the shape, thickness, and stiffness of the profiles to maximize energy capture and minimize fatigue. Furthermore, FRP pultrusion profiles offer good fatigue resistance, meaning they can withstand repeated loading cycles without experiencing significant degradation in performance. This is essential for wind turbine blades that are subjected to cyclic loading due to wind gusts and changes in wind direction. Finally, FRP pultrusion profiles are also electrically non-conductive, which is advantageous for wind turbine blades as it eliminates the risk of electrical discharge during operation. Overall, the lightweight, strong, corrosion-resistant, and customizable nature of FRP pultrusion profiles make them an excellent choice for the construction of wind turbine blades, contributing to the development of more efficient and durable wind energy systems.

- Q: Can FRP pultrusion profiles be used in the construction of highway guardrails?

- Yes, FRP pultrusion profiles can be used in the construction of highway guardrails. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent strength-to-weight ratio, corrosion resistance, and durability, making them a suitable choice for guardrails. They are lightweight, easy to install, and require minimal maintenance, making them cost-effective in the long run. Additionally, FRP profiles can be molded into various shapes and sizes to meet specific design requirements, ensuring the safety and effectiveness of the highway guardrails.

- Q: How do FRP pultrusion profiles handle torsion loads?

- FRP pultrusion profiles are designed to handle torsion loads effectively due to their inherent properties. The continuous fibers in the profile provide excellent resistance to torsional forces, ensuring high strength and stability. The pultrusion manufacturing process also allows for precise control over the fiber orientation, resulting in profiles that can efficiently handle torsion loads without compromising their structural integrity.

- Q: What is the impact resistance of FRP pultrusion profiles?

- The impact resistance of FRP (Fiber Reinforced Polymer) pultrusion profiles is generally quite high. FRP pultrusion profiles are made by pulling reinforcing fibers, such as fiberglass, through a resin bath and then into a heated die, where the resin cures and solidifies. This manufacturing process creates a strong and durable composite material with excellent mechanical properties, including impact resistance. The specific impact resistance of FRP pultrusion profiles can vary depending on the specific formulation and design of the profile, as well as the type and orientation of the reinforcing fibers used. However, in general, FRP pultrusion profiles have been found to have superior impact resistance compared to traditional materials like steel or aluminum. The combination of the reinforcing fibers and the resin matrix in FRP pultrusion profiles provides enhanced strength and toughness, which allows the profiles to withstand high impact loads without cracking, breaking, or deforming. This makes FRP pultrusion profiles suitable for a wide range of applications where impact resistance is critical, such as in construction, transportation, and sporting goods. Furthermore, FRP pultrusion profiles can be designed to have varying levels of impact resistance by adjusting the fiber content, fiber orientation, resin type, and other factors during the manufacturing process. This allows for customization of the profiles based on specific application requirements. In conclusion, FRP pultrusion profiles offer excellent impact resistance due to the combination of reinforcing fibers and resin matrix. Their high strength, toughness, and ability to withstand impact loads make them a reliable choice for various industries and applications.

- Q: Can FRP pultrusion profiles be used in telecommunications towers?

- Telecommunications towers can indeed utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess several advantageous features that render them suitable for this particular application. Firstly, FRP profiles possess a lightweight yet robust nature, facilitating effortless installation and reducing the overall structural weight of telecommunications towers. This characteristic is crucial as it aids in minimizing the burden imposed on the tower structure. Secondly, FRP pultrusion profiles exhibit exceptional resistance to corrosion, making them ideally suited for outdoor applications such as telecommunications towers that are constantly exposed to diverse environmental conditions. Unlike conventional materials like steel or wood, FRP profiles do not succumb to rust, rot, or deterioration when subjected to moisture, UV radiation, or chemicals typically encountered in outdoor environments. Additionally, FRP pultrusion profiles offer excellent electrical insulation properties, a critical aspect for telecommunications towers. These profiles are non-conductive, thereby reducing the likelihood of electrical interference or short circuits that might disrupt the tower's communication systems. Moreover, FRP pultrusion profiles can be produced in various shapes and sizes, thereby enabling customization and meeting the specific design requirements of telecommunications towers. This versatility facilitates seamless integration and compatibility with other components of the tower. Overall, the combination of lightweight composition, high strength, corrosion resistance, electrical insulation, and customization options renders FRP pultrusion profiles an advantageous and viable selection for utilization in telecommunications towers.

- Q: Are FRP pultrusion profiles resistant to hydrochloric acid?

- Yes, FRP pultrusion profiles are generally resistant to hydrochloric acid due to the corrosion-resistant properties of the fiberglass reinforcement and the resin matrix used in their construction. However, the specific resistance may vary depending on the composition and concentration of the acid, and it is recommended to consult the manufacturer's specifications for detailed information regarding chemical resistance.

- Q: Can FRP pultrusion profiles be used in electrical insulation applications?

- Yes, FRP pultrusion profiles can be used in electrical insulation applications. FRP (Fiber Reinforced Polymer) materials have excellent electrical insulation properties, making them suitable for a wide range of electrical applications. The pultrusion process ensures that the profiles have uniform insulation properties and high strength, making them ideal for use in electrical insulation applications.

- Q: Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Indeed, FRP pultrusion profiles have the capability to be utilized in wastewater treatment facilities. These profiles possess numerous benefits, including a high strength-to-weight ratio, resistance to corrosion, and durability, all of which make them highly suitable for the challenging conditions found in such facilities. In wastewater treatment facilities, there exists a wide range of applications where FRP pultrusion profiles can be effectively employed. These applications encompass walkways, handrails, ladders, grating, and structural supports, among others. The corrosion resistance of FRP makes it particularly well-suited for deployment in areas that are exposed to moisture and the chemicals present in wastewater. Furthermore, the lightweight nature of FRP profiles simplifies the installation process and reduces the burden placed on supporting structures. The durability of FRP pultrusion profiles guarantees long-term performance, even in aggressive environments. They exhibit a remarkable resistance to chemical attacks, UV radiation, and bacterial growth, rendering them highly appropriate for wastewater treatment applications. Additionally, FRP profiles can be tailored to meet specific load requirements and can be easily fabricated to accommodate various shapes and sizes. Furthermore, FRP pultrusion profiles possess outstanding electrical insulation properties, which can prove advantageous in wastewater treatment facilities where electrical safety is of utmost concern. To summarize, FRP pultrusion profiles can be effectively employed in wastewater treatment facilities due to their corrosion resistance, durability, lightweight nature, and versatility in terms of design and fabrication. These profiles provide long-lasting solutions for a variety of applications within these facilities, ensuring operational efficiency and minimizing maintenance needs.

- Q: Can FRP pultrusion profiles be used in the construction of chemical storage tanks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of chemical storage tanks. FRP materials are known for their excellent corrosion resistance properties, making them a suitable choice for storing a wide range of chemicals. Pultrusion profiles, which are made by pulling fiber reinforcements through a resin bath and then through a heated die, offer high strength-to-weight ratio, dimensional stability, and durability. FRP pultrusion profiles are non-reactive to most chemicals and are capable of withstanding harsh environments, including exposure to corrosive substances. They have low permeability, preventing chemicals from seeping through the tank walls. Additionally, FRP profiles can be customized to meet specific requirements, allowing for the construction of tanks with various shapes and sizes. Furthermore, FRP pultrusion profiles offer other advantages such as ease of installation, reduced maintenance, and long service life. They are lightweight, which simplifies transportation and installation processes. The low maintenance requirements of FRP tanks contribute to minimizing downtime and reducing overall costs. With proper design and construction, FRP pultrusion profiles can provide reliable and long-lasting solutions for chemical storage tank applications.

Send your message to us

FRP Pultrusion Profiles - Pultruded Gratings with Anti-Fatigue and Best Quality in Different Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords