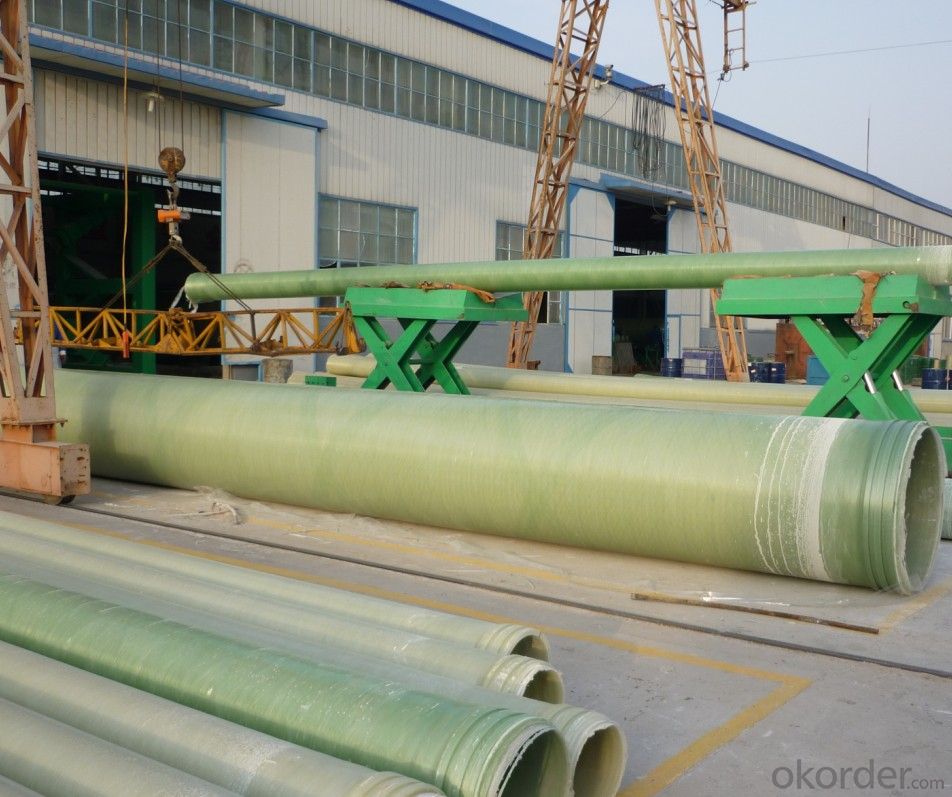

FRP Pultrusion Profiles - Lightweight and High-Strength FRP Pipes in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

1.PIPE INTRODUCTION

It is the ideal product for the transportations of the chemicals, drinking water, waste water, waste gas and sewer.

2.CHARACTERISTICS

• Corrosion resistance High mechanical property

• Low friction coefficient

• Light weight

• Non toxic

• Maintenance free

• Long life span

3.PRODUCTION RANGE

Any type and specification RPMP of diameter DN400-DN4000 and pressure PN0.25-PN2.5MPa can be produced. Also, we can provide the customized product according to user’s specific requirements.

TECHNICAL DATA

Stiffness | SN3750 | SN5000 | SN10000 | ||||||

Pressure | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 |

400 | 6.1 | 6.1 | 5.9 | 6.7 | 6.7 | 6.4 | 8.1 | 8.1 | 7.87 |

500 | 7.2 | 7.2 | 7.1 | 8 | 8 | 7.7 | 11.4 | 9.6 | 9.4 |

600 | 8.7 | 8.3 | 8.3 | 9.6 | 9.6 | 9.2 | 12.1 | 11.7 | 11 |

700 | 9.7 | 9.7 | 9.4 | 11.2 | 11.2 | 10.4 | 13.8 | 13.2 | 12.5 |

800 | 11.6 | 11.3 | 10.6 | 12.8 | 12.5 | 11.7 | 15.5 | 15 | 14.2 |

900 | 13.4 | 12.5 | 11.7 | 14.8 | 13.8 | 12.9 | 19.3 | 16.4 | 15.8 |

1000 | 14.6 | 13.7 | 13 | 16.2 | 15.1 | 14.4 | 20.7 | 18 | 17.3 |

1100 | 16.1 | 14.9 | 14.2 | 17.9 | 16.5 | 15.6 | 23 | 19.8 | 18.9 |

1200 | 17.2 | 16.1 | 15.4 | 19.6 | 17.9 | 16.9 | 24.7 | 21.5 | 20.6 |

1400 | 20.4 | 18.4 | 17.7 | 22.7 | 20.5 | 19.5 | 29.2 | 24.8 | 23.8 |

1500 | 22 | 19.9 | 18.7 | 24.4 | 22.1 | 20.7 | 31.4 | 26.3 | 25.3 |

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

FAQ

Q1.What's your sample policy?

A:We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q2.Can you produce according to the samples?

A: Yes, we can produce or modify the products according to your request.

Q3.How do you deliver the goods to my country?

A:We can provide international express, such as DHL, EMS, UPS, FedEx, etc. We select air freight and sea freight upon your requests. Quotations if without mentioning the shipping costs are shipping fee excluded.

Q4.How much does it cost to ship to my country?

A:When you goanna to place an order, please contact us, because different country has different freight.

Q5.How to get the catalogue?

A:please contact us and tell us what you are looking for.

We will try our best to meet customers' demands. Welcome you come here to visit us. We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

PICTURES

- Q: What does M23 grade of glass fiber reinforced plastic section mean?

- Glass fiber reinforced plastic profiles are mainly used in the field: general and environmental units of manhole covers, factories and mines units of insulated cable tray; chemical units of the transmission pipeline; insulation protection fence; including floor and so on. More fields. Advantage is obvious, if the corrosion resistance, insulation resistance, quality is lighter than steel; strength and steel strength comparable.

- Q: The manufacturing process of FRP products?

- 1, hand paste production method; 2, spray forming method; 3, fiber winding process; 4, molding process and molding process; 5, pultrusion method.

- Q: Can FRP pultrusion profiles be used in the transportation and logistics industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the transportation and logistics industry. FRP pultrusion profiles offer several advantages that make them suitable for various applications in this industry. Firstly, FRP pultrusion profiles are lightweight yet extremely strong and durable. This makes them ideal for use in transportation vehicles, such as trucks, trailers, and containers, where reducing weight is crucial for improving fuel efficiency and reducing emissions. Despite their lightweight nature, FRP pultrusion profiles can withstand heavy loads and harsh environmental conditions, ensuring their reliability and longevity. Secondly, FRP pultrusion profiles are highly corrosion-resistant. Unlike traditional materials, such as steel or aluminum, FRP does not rust or corrode when exposed to moisture or chemicals. This makes FRP profiles suitable for use in transportation and logistics applications that involve exposure to corrosive substances, such as saltwater, chemicals, or acidic environments. By using FRP pultrusion profiles, companies can reduce maintenance costs associated with corrosion and prolong the lifespan of their equipment. Additionally, FRP pultrusion profiles offer design flexibility. They can be manufactured in various shapes, sizes, and configurations to meet the specific requirements of transportation and logistics applications. Whether it is for structural components, platforms, flooring, or supports, FRP profiles can be customized to fit different needs, ensuring optimal performance and functionality. Moreover, FRP pultrusion profiles have excellent electrical and thermal insulation properties. This makes them suitable for applications where electrical conductivity needs to be minimized or thermal insulation is required. In the transportation and logistics industry, this can be beneficial for applications such as insulation for refrigerated containers or electrical insulation for specialized vehicles. In summary, FRP pultrusion profiles are well-suited for the transportation and logistics industry. Their lightweight, strong, durable, corrosion-resistant, and customizable nature, along with their electrical and thermal insulation properties, make them a reliable choice for various applications in this sector.

- Q: What are the load-bearing capabilities of FRP pultrusion profiles?

- The load-bearing capabilities of FRP pultrusion profiles vary depending on the specific profile design and the type of reinforcement used. However, FRP pultrusion profiles are known to have high strength-to-weight ratios and can generally handle heavy loads. They are often used in structural applications where strength and durability are important factors.

- Q: Will the FRP section crack for a long time?

- As long as the design of the structure is reasonable and the quality of the product conforms to the design requirements, the normal use shall not be cracked.

- Q: Are FRP pultrusion profiles resistant to fungi and mold?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fungi and mold. This is due to the non-porous nature of the materials used in their construction, such as fiberglass and epoxy resins. These materials do not provide a suitable environment for fungi and mold to grow, making FRP pultrusion profiles highly resistant to their growth and colonization. Furthermore, FRP pultrusion profiles are inherently moisture-resistant, which is another factor that discourages the growth of fungi and mold. Unlike traditional materials like wood, which can absorb moisture and provide a conducive environment for fungal and mold growth, FRP profiles do not absorb water and are therefore highly resistant to these issues. The combination of non-porous materials and moisture resistance makes FRP pultrusion profiles a suitable choice for applications where fungi and mold resistance is crucial, such as in humid or damp environments. However, it is important to note that no material is entirely immune to fungi and mold growth under all circumstances. In certain extreme conditions, where there is prolonged exposure to high levels of moisture and organic matter, it is still possible for some fungi and mold to colonize FRP profiles. However, compared to other materials, FRP pultrusion profiles offer a significantly higher level of resistance to these issues.

- Q: Can FRP pultrusion profiles be used in the automotive manufacturing industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the automotive manufacturing industry. FRP pultrusion profiles offer several advantages that make them suitable for automotive applications. Firstly, FRP profiles are lightweight, which helps in reducing the overall weight of the vehicle. This is crucial for improving fuel efficiency and reducing emissions. The lighter weight of FRP profiles also allows for better handling and improved performance. Secondly, FRP profiles possess excellent mechanical properties such as high strength and stiffness. This makes them suitable for use in structural components of vehicles, such as chassis, body panels, and frames. FRP profiles can withstand heavy loads and offer good impact resistance, ensuring the safety of the vehicle and its occupants. Additionally, FRP profiles exhibit excellent corrosion resistance, which is particularly beneficial for automotive applications. Unlike traditional materials like steel, FRP profiles are not susceptible to rust or corrosion, making them ideal for use in various automotive environments, including exposure to moisture, chemicals, and salt. Furthermore, FRP pultrusion profiles can be tailored to meet specific design requirements, allowing for flexibility in manufacturing. They can be produced in various shapes and sizes, offering versatility in designing complex components. This flexibility in design also allows for customization and optimization of vehicle performance. Lastly, FRP profiles offer good thermal and electrical insulation properties. This makes them suitable for applications where electrical conductivity needs to be minimized or thermal insulation is required. Overall, the lightweight, high strength, corrosion resistance, design flexibility, and insulation properties of FRP pultrusion profiles make them well-suited for use in the automotive manufacturing industry. They can contribute to the development of more efficient, safe, and durable vehicles.

- Q: Can FRP pultrusion profiles be used in chemical processing plants?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in chemical processing plants. FRP pultrusion profiles offer excellent corrosion resistance, making them suitable for chemical environments where exposure to different chemicals, acids, and bases is common. Additionally, FRP pultrusion profiles are lightweight, yet strong, and can be fabricated to meet specific design requirements, making them versatile for various applications within a chemical processing plant. They are also electrically non-conductive, which is beneficial in environments where electrical insulation is necessary. Overall, FRP pultrusion profiles provide a durable and cost-effective solution for chemical processing plants, offering long-term performance and reducing maintenance costs.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical packaging?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in pharmaceutical packaging. FRP pultrusion profiles are made of a combination of reinforced fibers and a polymer resin matrix, which provides them with excellent chemical resistance properties. The polymer resin used in FRP profiles is typically selected to be compatible with a wide range of chemicals, including those commonly used in pharmaceutical packaging. FRP profiles have been extensively used in various industries, including pharmaceuticals, due to their high chemical resistance. They are capable of withstanding exposure to a wide range of chemicals, such as acids, bases, solvents, and other aggressive substances commonly found in pharmaceutical packaging processes. This resistance helps protect the integrity of the packaging and ensures that there is no contamination or degradation of the pharmaceutical products. Additionally, FRP pultrusion profiles are also resistant to corrosion, which is another advantage in the pharmaceutical industry where aggressive chemicals may be present. This resistance to corrosion further enhances the durability and longevity of the FRP profiles, making them a reliable choice for pharmaceutical packaging applications. However, it is important to note that the specific chemical resistance of FRP pultrusion profiles may vary depending on the type and concentration of the chemicals being used. Therefore, it is recommended to consult the manufacturer or supplier of the FRP profiles to ensure their compatibility with the specific chemicals used in pharmaceutical packaging.

- Q: Are FRP pultrusion profiles resistant to impact?

- FRP pultrusion profiles exhibit a general resistance to impact. The amalgamation of robust fibers and the polymer matrix employed during manufacturing renders FRP profiles exceptionally enduring, enabling them to endure substantial impacts without fracturing or shattering. Furthermore, the pultrusion process guarantees the uniform dispersion of fibers within the profile, thereby bolstering its capacity to resist impact. Consequently, FRP pultrusion profiles are ideally suited for impact-prone applications, including construction, transportation, and infrastructure ventures.

Send your message to us

FRP Pultrusion Profiles - Lightweight and High-Strength FRP Pipes in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords