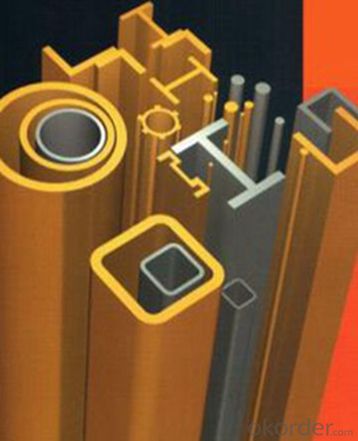

FRP Pultrusion Profiles - Lightweight, High Strength, and Quality FRP Gratings in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

Q1.What's your sample policy?

A:We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q2.Can you produce according to the samples?

A: Yes, we can produce or modify the products according to your request.

Q3.How do you deliver the goods to my country?

A:We can provide international express, such as DHL, EMS, UPS, FedEx, etc. We select air freight and sea freight upon your requests. Quotations if without mentioning the shipping costs are shipping fee excluded.

Q4.How much does it cost to ship to my country?

A:When you goanna to place an order, please contact us, because different country has different freight.

Q5.How to get the catalogue?

A:please contact us and tell us what you are looking for.

We will try our best to meet customers' demands. Welcome you come here to visit us. We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

PICTURES

- Q: How is FRP pultrusion different from other manufacturing processes?

- FRP pultrusion is different from other manufacturing processes in its unique method of producing fiber-reinforced polymer (FRP) profiles. Unlike traditional processes like extrusion or injection molding, pultrusion involves pulling continuous fibers through a resin bath and then into a heated die, where they are cured and shaped into the desired profile. This continuous and automated process allows for the production of strong, lightweight, and corrosion-resistant FRP profiles with consistent mechanical properties. Additionally, pultrusion enables the incorporation of various fiber orientations and resin systems, making it highly versatile for customized applications.

- Q: How do FRP pultrusion profiles perform in extreme heat temperatures?

- FRP pultrusion profiles are renowned for their exceptional performance in extreme heat conditions. The profiles acquire remarkable heat resistance properties due to the distinct combination of materials utilized in the pultrusion process, such as fiberglass reinforcement and thermosetting resin matrix. One of the primary benefits of FRP pultrusion profiles lies in their capacity to uphold dimensional stability even when subjected to elevated temperatures. Unlike conventional materials like steel or aluminum, which may expand or deform under extreme heat, FRP profiles retain their shape and structural integrity. Consequently, they offer a high level of reliability in applications where temperature fluctuations are frequent or where exposure to intense heat is prevalent. Furthermore, FRP pultrusion profiles possess exceptional thermal insulation properties. They possess a low thermal conductivity, effectively impeding heat transfer. This characteristic proves advantageous in situations where heat control or isolation is necessary, preventing the profiles from becoming excessively hot. Moreover, FRP pultrusion profiles boast a high heat distortion temperature (HDT). HDT refers to the temperature at which a material begins to deform under a specific load. Typically, the HDT of FRP profiles surpasses that of other materials, enabling them to endure extreme heat without compromising their structural integrity. In conclusion, FRP pultrusion profiles are highly suitable for use in extreme heat conditions. Their ability to maintain dimensional stability, resist heat transfer, and withstand high temperatures renders them a dependable choice for diverse industries, including aerospace, automotive, and infrastructure.

- Q: Are FRP pultrusion profiles resistant to high winds or hurricanes?

- FRP pultrusion profiles offer exceptional resistance against high winds and hurricanes. Combining the robustness of fiberglass with the longevity of polymers, FRP is a lightweight yet remarkably sturdy material that can endure severe weather conditions. Extensive testing has proven that FRP pultrusion profiles exhibit outstanding wind resistance properties. They possess a remarkable stiffness-to-weight ratio, enabling them to withstand the powerful forces generated by high winds without deformation or breakage. Additionally, the inherent flexibility of FRP permits it to absorb and distribute wind forces, minimizing the risk of damage. In the face of hurricanes, FRP pultrusion profiles have demonstrated their capability to withstand the intense winds and airborne debris associated with such extreme weather events. They have been successfully employed in various applications, including building facades, bridges, and utility poles, in areas prone to hurricanes. Moreover, FRP pultrusion profiles possess corrosion resistance, providing an extra advantage in withstanding high winds and hurricanes. Unlike traditional materials like steel or wood, FRP profiles do not rust or decay when exposed to moisture, making them even more suitable for these demanding weather conditions. Overall, with their exceptional strength, durability, flexibility, and corrosion resistance, FRP pultrusion profiles are an excellent choice for applications requiring resistance against high winds or hurricanes.

- Q: Can FRP pultrusion profiles be customized according to specific requirements?

- FRP pultrusion profiles can be tailored to specific requirements, offering a wide range of customization options. Pultrusion is a manufacturing process that involves pulling continuous fibers through a liquid resin bath and then curing the resin in a heated die to achieve the desired shape. This process allows for flexibility in design and customization. Customization possibilities for FRP pultrusion profiles include dimensions, shapes, colors, and surface finishes. The dimensions can be adjusted to meet specific length, width, and thickness needs. Shapes can vary from basic geometries like rectangular or round profiles to more intricate designs with unique cross-sections. When it comes to color, FRP pultrusion profiles can be pigmented during manufacturing to achieve the desired shade or can be painted or coated afterward. This allows for matching specific color requirements or ensuring compatibility with existing structures or products. Additionally, surface finishes can be personalized to attain desired properties such as enhanced slip resistance, UV resistance, or fire resistance. Specific performance requirements can be met by applying surface treatments like sanding, coating, or adding special additives. Overall, FRP pultrusion profiles offer a high level of customization, making them suitable for various industries including construction, transportation, infrastructure, and aerospace. They are versatile, lightweight, corrosion-resistant, and possess excellent strength-to-weight ratios.

- Q: Can FRP pultrusion profiles be used in high-voltage applications?

- Yes, FRP pultrusion profiles can be used in high-voltage applications. FRP (Fiber Reinforced Polymer) is a highly durable and electrically insulating material, making it suitable for use in high-voltage environments. The pultrusion process used to manufacture FRP profiles ensures that the material has a consistent and uniform composition, resulting in excellent electrical insulation properties. FRP pultrusion profiles have a high dielectric strength, meaning they can withstand high voltages without electrical breakdown. They also exhibit low electrical conductivity, preventing the flow of electric current through the material. This makes FRP profiles an ideal choice for applications where electrical insulation is crucial, such as high-voltage power transmission and distribution systems, electrical substations, and electrical equipment insulation. In addition to their electrical insulation properties, FRP pultrusion profiles offer several other advantages in high-voltage applications. They are lightweight, corrosion resistant, and have a high strength-to-weight ratio, making them easy to handle, install, and maintain. FRP profiles are also non-magnetic and non-conductive, reducing the risk of electromagnetic interference (EMI) in sensitive electrical systems. Overall, FRP pultrusion profiles are a reliable and efficient choice for high-voltage applications, providing excellent electrical insulation, durability, and performance in challenging environments.

- Q: Are FRP pultrusion profiles resistant to oils and greases?

- Yes, FRP pultrusion profiles are generally resistant to oils and greases. The combination of fiberglass reinforcement and resin matrix in FRP pultrusions provides excellent resistance to various chemicals, including oils and greases. This makes them suitable for applications where exposure to oils and greases is expected.

- Q: Are FRP pultrusion profiles resistant to termites or other pests?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are inherently resistant to termites and other pests. Unlike traditional wood or metal materials, FRP profiles do not provide a food source for termites or any other pests. FRP is composed of a combination of reinforced fibers and a polymer matrix, typically made of fiberglass and resin. These materials are not appealing to pests and do not provide any nutritional value, making FRP profiles highly resistant to termite damage or infestation. This resistance to pests is one of the many advantages of using FRP pultrusion profiles in various applications, especially in outdoor or humid environments where termites are commonly found.

- Q: Are FRP pultrusion profiles resistant to fire?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fire. The composition of FRP includes a resin matrix and reinforcing fibers, such as fiberglass or carbon fiber, which provide excellent fire resistance properties. The resin matrix used in FRP typically has a high flame resistance rating, and the reinforcing fibers do not burn easily. As a result, FRP pultrusion profiles have a high ignition temperature and are inherently self-extinguishing, meaning they will not continue to burn once the flame source is removed. Additionally, FRP pultrusion profiles do not release toxic fumes or smoke when exposed to fire, making them a safer alternative to traditional materials like wood or steel. However, it is important to note that the fire resistance of FRP pultrusion profiles can vary depending on the specific resin formulation and reinforcement material used.

- Q: Can FRP pultrusion profiles be used in chemical processing plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be utilized in chemical processing plants. FRP is resistant to corrosion, chemicals, and extreme temperatures, making it an ideal material choice in such environments. Additionally, FRP pultrusion profiles offer high strength-to-weight ratio and low maintenance requirements, making them suitable for various applications within chemical processing plants.

- Q: Can FRP pultrusion profiles be used in the construction industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction industry. FRP pultruded profiles offer several advantages that make them suitable for various construction applications. Firstly, FRP pultrusion profiles are lightweight yet exceptionally strong. This makes them an excellent choice for construction projects as they provide high strength-to-weight ratio, reducing the overall weight of the structure while maintaining structural integrity. This can be particularly advantageous in applications such as bridges, walkways, and platforms. Secondly, FRP pultrusion profiles are highly corrosion resistant. Unlike traditional construction materials like steel or wood, FRP does not rust, rot, or corrode when exposed to harsh environmental conditions, chemicals, or moisture. This makes FRP profiles ideal for outdoor or marine applications where corrosion is a concern, such as seawalls, docks, or offshore structures. Additionally, FRP pultrusion profiles have excellent electrical and thermal insulation properties. This makes them suitable for applications where electrical conductivity needs to be minimized, such as electrical enclosures or cable trays. FRP profiles also have low thermal conductivity, which can help improve energy efficiency in buildings by reducing heat transfer. Furthermore, FRP pultrusion profiles are highly durable and require minimal maintenance. They have a long service life and do not require regular painting, sealing, or treatment like traditional materials. This can result in significant cost savings over the life cycle of a construction project. Lastly, FRP pultrusion profiles can be designed to meet specific strength, stiffness, and dimensional requirements. They can be manufactured in various shapes, sizes, and colors, allowing for flexibility in design and customization. This versatility makes FRP profiles suitable for a wide range of construction applications, including beams, columns, gratings, handrails, and structural components. In summary, FRP pultrusion profiles are a viable option for the construction industry due to their lightweight, high strength, corrosion resistance, electrical and thermal insulation properties, durability, low maintenance requirements, and design flexibility.

Send your message to us

FRP Pultrusion Profiles - Lightweight, High Strength, and Quality FRP Gratings in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords