FRP Pultrusion Profiles Fiberglass Plank Deck Flooring Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

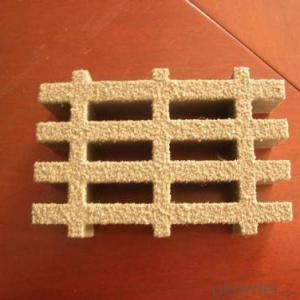

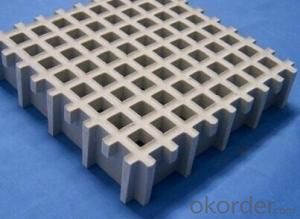

FRP flooring panel is a big size profile which is made by pultrusion technology and in holistic shape, it could form a continuours close plane by unique self-lock structure,which could be used as load structures in various corrosion environments and could replace wood plate, aluminum plate or steel plate etc.

The product could add natural color grit on the surface,which is safe for the anti-slippery,besides it could obtain

the natural appearance and no fadding for a long time.

FEATURES

1.Electrically and thermally non-conductive

2.Ultra-violet resistant

3.Provided in a number of gratings thickness and panel sizes with many types of mesh size

4.Offers bi-directional strength characteristic

5.Impact resistance

6.insulationt

SPECIFICATIONS

Item | Size(mm) | Weight(kg/m) |

01 | 25×25x3.2x3.2 | 0.52 |

02 | 32x32x3.2x3.2 | 0.68 |

03 | 38x38x4x4 | 0.98 |

04 | 50x50x4x4 | 1.36 |

05 | 50x50x5x5 | 1.67 |

06 | 50x50x6.3x6.3 | 2.06 |

07 | 60x60x7x7 | 3.2 |

08 | 100x100x6x6 | 4.56 |

09 | 38x38x7x7 | 2.02 |

PICTURES

- Q: Can FRP pultrusion profiles be used in wastewater or sewage treatment plants?

- Yes, FRP pultrusion profiles can be used in wastewater or sewage treatment plants. FRP (Fiber Reinforced Plastic) materials offer excellent corrosion resistance, high strength-to-weight ratio, and durability, making them suitable for harsh environments like wastewater treatment facilities. These profiles can be used for various applications such as gratings, handrails, ladders, walkways, and structural supports, providing a long-lasting and low-maintenance solution for these facilities.

- Q: Can FRP pultrusion profiles be used in the construction of outdoor signage?

- Certainly, outdoor signage can utilize FRP pultrusion profiles. These profiles possess remarkable qualities, including durability, strength, and the ability to withstand different environmental conditions, rendering them ideal for outdoor use. Typically, these profiles consist of a combination of fiberglass reinforcement and resin matrix, resulting in a lightweight yet robust material. Outdoor signage often confronts harsh weather conditions, such as rain, sun exposure, and temperature fluctuations. FRP pultrusion profiles exhibit excellent resistance to corrosion, UV rays, and moisture, ensuring that the signage retains its structural integrity and visual appeal over time. Moreover, FRP pultrusion profiles offer customization options to fulfill specific design requirements, offering flexibility in creating distinctive and captivating outdoor signage. These profiles can be effortlessly shaped, cut, and assembled, making them a versatile choice for signage applications. In essence, the construction of outdoor signage can undoubtedly benefit from the use of FRP pultrusion profiles due to their durability, resistance to environmental conditions, and design flexibility.

- Q: How do FRP pultrusion profiles handle cyclic loading?

- FRP pultrusion profiles are known for their excellent performance under cyclic loading conditions. The unique combination of materials and manufacturing process used in pultrusion makes these profiles highly resistant to fatigue and cyclic loading effects. One key factor that contributes to the superior performance of FRP pultrusion profiles under cyclic loading is their inherent high strength-to-weight ratio. These profiles are made using continuous fibers, typically fiberglass, which are impregnated with a resin matrix. This results in a lightweight yet strong material that can handle repeated loading without experiencing significant degradation or fatigue. Additionally, the pultrusion process allows for precise control over the fiber orientation and resin distribution within the profile. This results in a uniform and consistent material composition throughout the entire length of the profile. As a result, FRP pultrusion profiles exhibit excellent load distribution characteristics, minimizing stress concentrations and preventing localized failure under cyclic loading conditions. Furthermore, the corrosion resistance of FRP pultrusion profiles plays a crucial role in their ability to handle cyclic loading. Unlike traditional materials such as steel, FRP profiles do not suffer from corrosion-related issues, such as rust or pitting. This corrosion resistance ensures that the profiles maintain their structural integrity even when subjected to cyclic loading over extended periods of time. Overall, FRP pultrusion profiles are specifically designed and manufactured to withstand cyclic loading conditions. Their high strength-to-weight ratio, uniform material composition, and corrosion resistance make them ideal for applications where cyclic loading is a significant factor. Whether it's in structural reinforcements, bridges, sporting equipment, or various industrial applications, FRP pultrusion profiles have proven to be reliable and durable under cyclic loading.

- Q: Can FRP pultrusion profiles be used in the water treatment industry?

- Indeed, the water treatment industry can make use of FRP pultrusion profiles. These profiles, made of Fiber Reinforced Polymer, are widely recognized for their exceptional resistance to corrosion, impressive strength, and long-lasting durability. These qualities render them highly appropriate for a diverse range of applications within the water treatment field. In particular, FRP pultrusion profiles can be employed in the construction of water treatment tanks, pipes, and other crucial infrastructure. They exhibit remarkable resistance to chemicals, including those commonly employed in water treatment procedures. This resistance to corrosion ensures that equipment enjoys an extended lifespan and maintenance costs are minimized. Moreover, FRP pultrusion profiles boast an impressive strength-to-weight ratio, making them an ideal choice for applications that necessitate lightweight yet robust materials. This quality facilitates the easier installation and transportation of water treatment equipment. Furthermore, the flexibility in design offered by FRP pultrusion profiles is worth noting. Such profiles can be manufactured in a wide array of shapes and sizes to cater to specific project requirements. This capability allows for the customization and optimization of water treatment systems, guaranteeing the efficiency and effectiveness of water treatment processes. In summary, FRP pultrusion profiles present themselves as a dependable and cost-effective option for the water treatment industry. Their excellent resistance to corrosion, exceptional strength, and design flexibility make them highly suitable for numerous applications within water treatment systems.

- Q: Are FRP pultrusion profiles resistant to fungal growth?

- Yes, FRP pultrusion profiles are highly resistant to fungal growth. The composite materials used in FRP pultrusion, such as fiberglass and resin, do not provide a suitable environment for fungi to grow. Additionally, the smooth surface of FRP profiles makes it difficult for fungi to attach and thrive. Hence, FRP pultrusion profiles are an excellent choice for applications where resistance to fungal growth is required.

- Q: Are FRP pultrusion profiles resistant to moisture absorption?

- Yes, FRP pultrusion profiles are highly resistant to moisture absorption. The inherent properties of the fiberglass and resin used in pultrusion manufacturing make the profiles highly durable and impervious to moisture, ensuring long-term performance and minimal structural damage.

- Q: Can FRP pultrusion profiles be used in the construction and building materials industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can certainly be used in the construction and building materials industry. FRP pultrusion profiles are made by pulling continuous fibers through a resin bath and then into a heated die, which helps to cure the resin and shape the profile. One of the main advantages of FRP pultrusion profiles is their high strength-to-weight ratio. They are incredibly strong and durable, yet lightweight, making them an ideal choice for construction applications where weight reduction is desired. Additionally, FRP pultrusion profiles have excellent corrosion resistance, which is particularly beneficial in environments where moisture, chemicals, or harsh weather conditions may be present. This corrosion resistance extends the lifespan of building materials, reducing maintenance and replacement costs. FRP pultrusion profiles can be used in a wide range of construction applications, including structural components such as beams, columns, and trusses. They are also commonly used as reinforcements in concrete structures, providing additional strength and durability. In addition, FRP pultrusion profiles can be used for cladding, decking, handrails, ladders, and other non-structural elements in buildings. Furthermore, FRP pultrusion profiles offer design flexibility, as they can be easily customized and manufactured to specific shapes, sizes, and properties. This adaptability makes them suitable for a variety of construction projects, from small-scale residential buildings to large-scale industrial complexes. In summary, FRP pultrusion profiles are highly suitable for the construction and building materials industry due to their high strength-to-weight ratio, corrosion resistance, design flexibility, and versatility.

- Q: How do FRP pultrusion profiles handle bending and flexing?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are highly durable and can handle bending and flexing quite effectively. The unique manufacturing process of pultrusion, which involves pulling reinforcing fibers through a resin bath and then curing it in a heated die, results in a composite material with exceptional strength-to-weight ratio. When it comes to bending, FRP pultrusion profiles exhibit excellent flexibility. The reinforcing fibers, such as fiberglass or carbon fibers, provide the necessary tensile strength to resist bending forces. Additionally, the resin matrix that surrounds the fibers provides a degree of elasticity, allowing the profiles to flex without breaking or permanently deforming. The specific design of the pultrusion profile also influences its bending and flexing capabilities. By varying the arrangement, orientation, and number of reinforcing fibers, manufacturers can tailor the profiles to meet specific application requirements. This allows for enhanced strength and flexibility in desired directions while maintaining structural integrity. Furthermore, FRP pultrusion profiles offer inherent resistance to corrosion, moisture, and chemicals, making them ideal for applications in harsh environments. These properties ensure that the profiles do not weaken or degrade over time, even when subjected to repeated bending and flexing. Overall, FRP pultrusion profiles are well-suited for handling bending and flexing due to their inherent strength, flexibility, and resistance to environmental factors. Their ability to maintain structural integrity under such conditions makes them a reliable choice for various industries, including construction, infrastructure, aerospace, and automotive.

- Q: Can FRP pultrusion profiles be used in oil and gas applications?

- FRP pultrusion profiles are applicable for oil and gas purposes. These profiles possess exceptional resistance against corrosion, a high strength-to-weight ratio, and durability, making them suitable for a range of industries, including oil and gas. In oil and gas applications, FRP pultrusion profiles can serve multiple functions. They find use in constructing pipelines, offshore platforms, and subsea structures. They can also be utilized for fabricating tanks, vessels, and other equipment that are exposed to corrosive environments. A key advantage of FRP pultrusion profiles in oil and gas applications is their resistance to corrosion. Unlike traditional materials like steel, FRP does not rust or corrode when exposed to moisture, chemicals, or saltwater. This resistance extends the lifespan of the profiles and reduces maintenance costs. Furthermore, FRP pultrusion profiles offer high strength and stiffness. They can withstand high pressures, extreme temperatures, and harsh operating conditions commonly encountered in oil and gas environments. Their lightweight nature also facilitates easier handling and installation, especially when compared to heavier materials such as steel. Another benefit of FRP profiles is their non-conductive property. This characteristic makes them suitable for applications where electrical conductivity should be minimized, such as offshore platforms or areas with potential electrical hazards. In conclusion, FRP pultrusion profiles are a reliable and cost-effective solution for oil and gas applications. Their corrosion resistance, high strength, and lightweight properties make them ideal for various components and structures within the industry.

- Q: Can FRP pultrusion profiles be used in the construction of chemical storage tanks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of chemical storage tanks. FRP materials are known for their excellent corrosion resistance properties, making them a suitable choice for storing a wide range of chemicals. Pultrusion profiles, which are made by pulling fiber reinforcements through a resin bath and then through a heated die, offer high strength-to-weight ratio, dimensional stability, and durability. FRP pultrusion profiles are non-reactive to most chemicals and are capable of withstanding harsh environments, including exposure to corrosive substances. They have low permeability, preventing chemicals from seeping through the tank walls. Additionally, FRP profiles can be customized to meet specific requirements, allowing for the construction of tanks with various shapes and sizes. Furthermore, FRP pultrusion profiles offer other advantages such as ease of installation, reduced maintenance, and long service life. They are lightweight, which simplifies transportation and installation processes. The low maintenance requirements of FRP tanks contribute to minimizing downtime and reducing overall costs. With proper design and construction, FRP pultrusion profiles can provide reliable and long-lasting solutions for chemical storage tank applications.

Send your message to us

FRP Pultrusion Profiles Fiberglass Plank Deck Flooring Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords