Pultruded FRP Fiberglass Deck Flooring Panel, Fiberglass Deck Boards

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP flooring panel is a big size profile which is made by pultrusion technology and in holistic shape, it could form a continuours close plane by unique self-lock structure,which could be used as load structures in various corrosion environments and could replace wood plate, aluminum plate or steel plate etc.

The product could add natural color grit on the surface,which is safe for the anti-slippery,besides it could obtain the natural appearance and no fadding for a long time.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

TECHNICAL DATA

Thickness (mm) | Bar width (mm) | Openspace (mm) | Open rate (%) | Approx weight (kg/m 2 ) |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

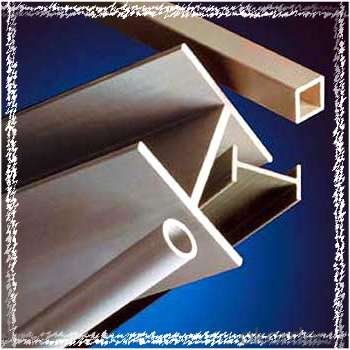

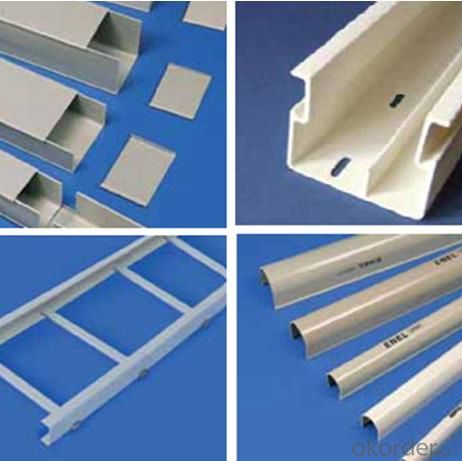

PICTURES

APPLICATION

Deck of cooling tower, plate of scaffold, floor of chip manufacturing, deck of bridge, rooftop, slope of architectural

overhaul, structural floor, floor of light railcar, baffle of equipment, roof of cover, trench cover, footpath, weather

plank.

- Q: Are FRP pultrusion profiles resistant to oil and grease?

- FRP (Fiber Reinforced Plastic) pultrusion profiles are generally known for their excellent resistance to oil and grease. The combination of fibers, typically glass or carbon, with a polymer resin matrix results in a material that is inherently resistant to many chemicals, including oil and grease. This resistance is attributed to the non-reactive nature of the polymer resin, which prevents the oil or grease from penetrating the material and causing damage. Additionally, the pultrusion manufacturing process used to produce FRP profiles further enhances their resistance to oil and grease. During the pultrusion process, the fibers are impregnated with the resin and then pulled through a heated die, where the resin is cured. This creates a strong, uniform material with a dense surface that is less porous and more resistant to chemical penetration. It is important to note that the specific resistance of FRP pultrusion profiles to oil and grease can vary depending on the type of resin used and the specific application conditions. In some cases, specialized resin formulations can be used to further enhance the oil and grease resistance of FRP profiles, ensuring suitability for even more demanding environments. Overall, FRP pultrusion profiles are generally considered to be highly resistant to oil and grease, making them an excellent choice for applications where exposure to these substances is expected. However, it is always recommended to consult with the manufacturer or supplier to ensure that the specific FRP profile being used is appropriate for the intended application and chemical exposure.

- Q: Are FRP pultrusion profiles resistant to high-pressure gas?

- Yes, FRP pultrusion profiles are generally resistant to high-pressure gas due to their excellent corrosion resistance and structural integrity. The inherent properties of FRP, such as high strength-to-weight ratio and non-reactivity to gases, make them suitable for various applications involving high-pressure gas environments. However, it is recommended to consult with the manufacturer or engineer to ensure specific requirements are met for the intended application.

- Q: Can FRP pultrusion profiles be used in the construction of amusement park rides?

- Amusement park rides can utilize FRP pultrusion profiles due to their various advantages. Firstly, these profiles have a high strength-to-weight ratio, making them lighter than steel without compromising structural integrity. Consequently, the weight of the ride's structure can be reduced while maintaining safety. Secondly, FRP pultrusion profiles possess exceptional resistance to corrosion. Unlike steel, they do not rust or deteriorate when exposed to moisture or chemicals commonly found in amusement parks. This makes them ideal for rides constantly exposed to water, humidity, and harsh conditions. Moreover, these profiles offer design flexibility, allowing for customized shapes and sizes that meet specific requirements of amusement park rides. This versatility enables engineers and designers to create intricate and aesthetically pleasing structures. Furthermore, FRP pultrusion profiles provide excellent electrical insulation, ensuring a high level of safety for rides with electrical components and wiring. Additionally, these profiles are non-magnetic, which is advantageous for rides utilizing magnetic systems or sensors. Non-magnetic materials eliminate the risk of interference or disruption to the ride's functionality. Lastly, FRP pultrusion profiles are durable and require minimal maintenance. They are resistant to UV radiation, preventing degradation or fading due to prolonged sunlight exposure. This reduces the need for frequent painting or coating, resulting in lower maintenance costs over time. In conclusion, the combination of lightweight, corrosion resistance, design flexibility, electrical insulation, non-magnetic properties, and durability make FRP pultrusion profiles an excellent choice for constructing amusement park rides.

- Q: Can FRP pultrusion profiles be used in high-voltage applications?

- Yes, FRP pultrusion profiles can be used in high-voltage applications. FRP (Fiber Reinforced Polymer) materials are known for their excellent electrical insulation properties, making them suitable for high-voltage environments. Additionally, FRP pultrusion profiles offer advantages such as high strength, corrosion resistance, and lightweight, making them a viable option for high-voltage applications.

- Q: Can FRP pultrusion profiles be used in renewable energy projects?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can certainly be used in renewable energy projects. FRP pultrusion profiles offer a wide range of advantages that make them suitable for various applications within the renewable energy sector. Firstly, FRP pultrusion profiles are lightweight yet strong, making them ideal for use in wind turbine blades. The lightweight nature of FRP materials allows for increased efficiency in wind energy generation by reducing the load on the turbine, thus improving overall performance. Additionally, the high strength-to-weight ratio of FRP profiles ensures durability and longevity, even in harsh environmental conditions. Secondly, FRP pultrusion profiles exhibit excellent corrosion resistance, making them suitable for solar panel mounting structures and other components exposed to moisture and outdoor elements. This corrosion resistance ensures that FRP profiles maintain their structural integrity and performance over an extended period of time, reducing the need for frequent maintenance and replacement. Thirdly, FRP pultrusion profiles can be customized to meet specific project requirements, allowing for flexibility in design and functionality. They can be easily molded into complex shapes and sizes, enabling the creation of innovative and efficient solutions for renewable energy projects. Moreover, FRP materials are non-conductive and have excellent electrical insulation properties, making them suitable for use in electrical enclosures and support structures for renewable energy systems such as solar power plants. In conclusion, FRP pultrusion profiles can be effectively utilized in renewable energy projects due to their lightweight, strong, corrosion-resistant, customizable, and electrically-insulating properties. These characteristics make FRP profiles a reliable and sustainable choice for various applications within the renewable energy sector.

- Q: Can FRP pultrusion profiles be customized according to specific requirements?

- Yes, FRP pultrusion profiles can be customized according to specific requirements. Pultrusion is a manufacturing process that allows for the creation of complex shapes and sizes, making it possible to tailor the FRP profiles to meet specific design and performance criteria. This customization can include modifications in dimensions, reinforcement types, resin systems, color, surface finish, and various other parameters to ensure they meet the desired specifications and needs of the application.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of chemical reactors?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of chemical reactors. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent resistance to corrosion, high strength-to-weight ratio, and dimensional stability, making them ideal for use in chemical reactors. Additionally, FRP materials can withstand a wide range of chemical environments and temperatures, making them a reliable choice for this application.

- Q: Can FRP pultrusion profiles be used in the oil and gas industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the oil and gas industry. FRP pultrusion profiles offer several advantages that make them suitable for applications in this industry. Firstly, FRP pultrusion profiles are corrosion-resistant. They do not rust, corrode, or degrade when exposed to harsh environments, such as saltwater, chemicals, and extreme temperatures. This makes them ideal for use in offshore platforms, pipelines, and other oil and gas facilities where corrosion can be a significant issue. Secondly, FRP pultrusion profiles have high strength-to-weight ratio. They are lightweight yet extremely strong, allowing for efficient installation, transportation, and handling. This is particularly beneficial in the oil and gas industry, where weight reduction is a crucial factor in improving operational efficiency and reducing costs. Thirdly, FRP pultrusion profiles can be customized to meet specific requirements. They can be manufactured in various shapes, sizes, and configurations, making them versatile for different applications in the oil and gas industry. Whether it is for structural supports, grating, handrails, or other components, FRP pultrusion profiles can be tailored to fit the specific needs of each project. Furthermore, FRP pultrusion profiles offer excellent electrical insulation properties. This is important in the oil and gas industry, where electrical safety is paramount. FRP profiles can provide insulation and prevent electrical conductivity, reducing the risk of accidents and ensuring the safety of personnel and equipment. Overall, FRP pultrusion profiles have proven to be reliable, durable, and cost-effective solutions for various applications in the oil and gas industry. Their corrosion resistance, high strength-to-weight ratio, customization capabilities, and electrical insulation properties make them an attractive choice for this demanding industry.

- Q: Can FRP pultrusion profiles be used in pedestrian bridges?

- FRP pultrusion profiles can indeed be utilized in pedestrian bridges. They possess several advantages that render them appropriate for bridge construction, including their exceptional strength-to-weight ratio, resistance to corrosion, and durability. These profiles are manufactured by pulling continuous fibers through a resin bath and subsequently through a heated die, yielding a material that is both robust and lightweight. The lightweight nature of FRP pultrusion profiles makes them an ideal choice for pedestrian bridges, as they can be easily transported and installed. Furthermore, their high strength enables them to withstand the load requirements imposed by pedestrian traffic. Moreover, these profiles exhibit exceptional resistance to corrosion, which is particularly crucial for bridges that are exposed to environmental elements such as rain, humidity, and saltwater. In addition, FRP pultrusion profiles are highly durable and necessitate minimal maintenance in comparison to traditional construction materials like steel or concrete. They are impervious to rust or rot, and their non-conductive properties guarantee their safety when employed in areas with electrical infrastructure. To summarize, FRP pultrusion profiles present a suitable option for pedestrian bridges due to their lightweight nature, high strength, resistance to corrosion, and durability. These profiles offer a cost-effective and long-lasting solution for bridge construction, ensuring the safety and convenience of pedestrians.

- Q: Can FRP pultrusion profiles be used in the construction and building materials industry?

- Yes, FRP pultrusion profiles can be effectively used in the construction and building materials industry. These profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and dimensional stability, making them suitable for a wide range of applications including structural elements, handrails, gratings, and reinforcements. Additionally, FRP pultrusion profiles can be easily customized to meet specific project requirements, making them a popular choice in the industry.

Send your message to us

Pultruded FRP Fiberglass Deck Flooring Panel, Fiberglass Deck Boards

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords