FRP Pultrusion Profiles for Power Steel Paper Plant Grating Floor Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

FRP molded grating made of vertical and horizontal continuous fiberglass fully soaked in unsaturated polyester resin giving perfect bi-directional mechanical properties. Combining unmatched corrosion resistance with strength, long life and safety, molded grating provide the ultimate in reliable performance, even in the most demanding corrosive conditions. Besides, it is easy to cut and install. CNBM offer the widest selection with panel sizes, colors and slip resistant surfaces, clients can avail FRP grating your specific requirements.

Product Features:

- Light but high loaded strength

- High anti-corrosion and anti-aging

- Easy installation and maintenance

- Low maintenance

- Non-conductive

- Lowest in life cycle cost

- Corrosion Resstance

- Anti-slippery

- Various sizes and color available

Colour Design:

To satisfy customer's design project, CNBM grating offers a wide selection of grating colors to choose from. The standard colors available for fiberglass grating as following:

- Blue

- Red

- Yellow

- Green

- Light Grey

- Dark Grey

Custom colors of fiberglass grating may be available upon request, you can contact us learn more.

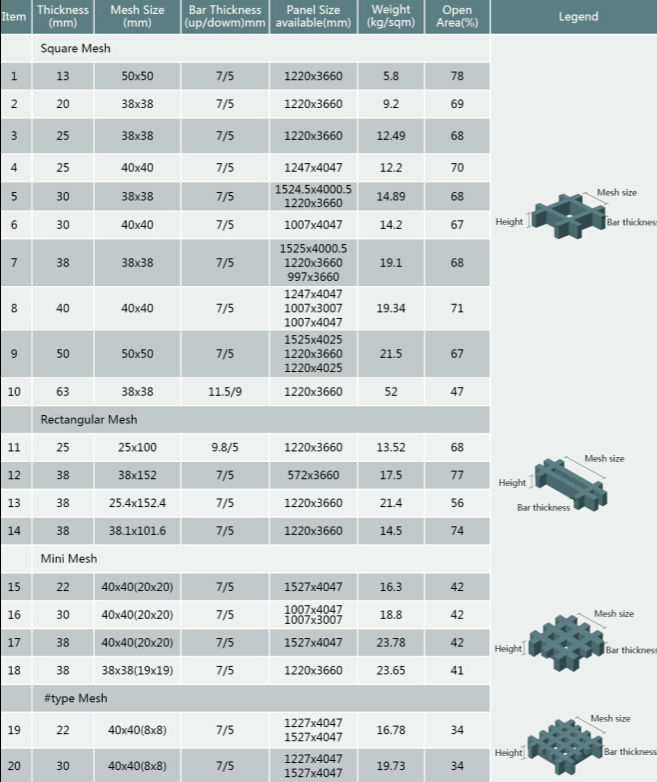

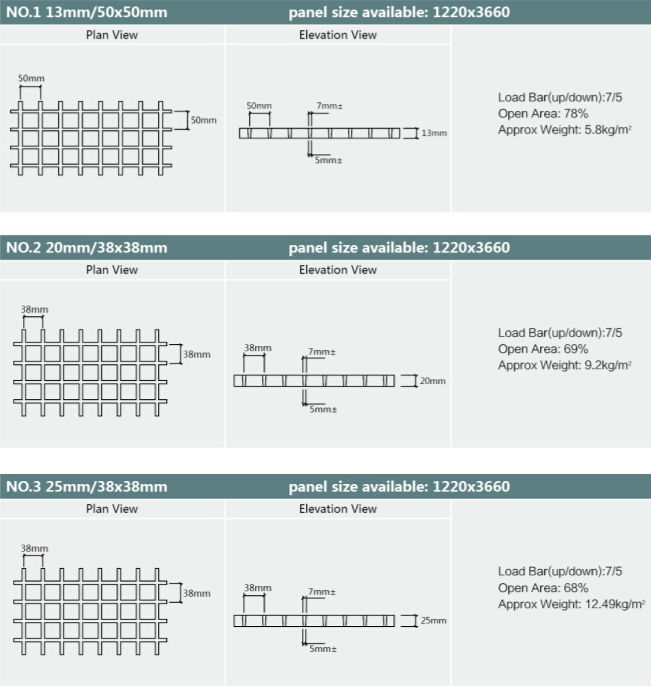

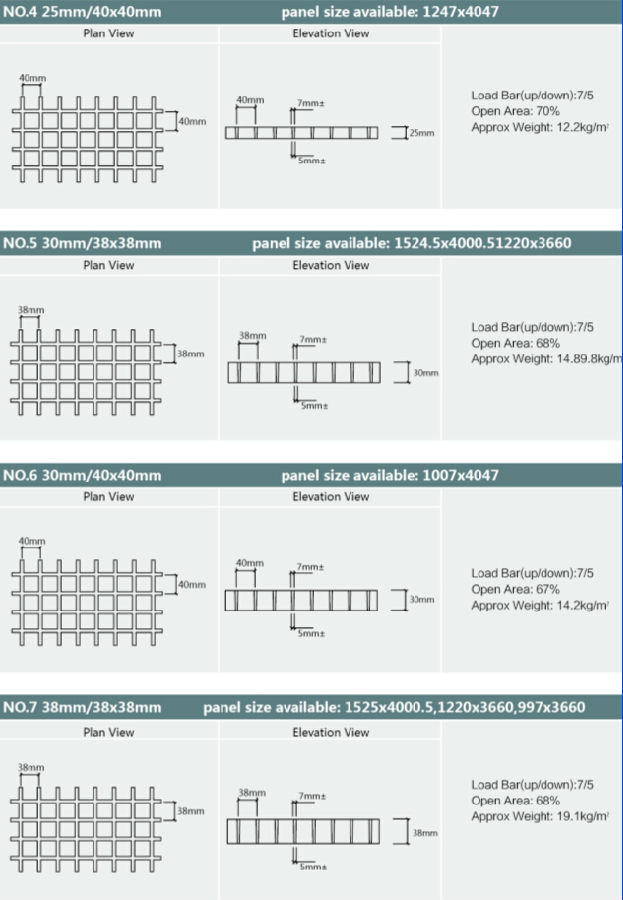

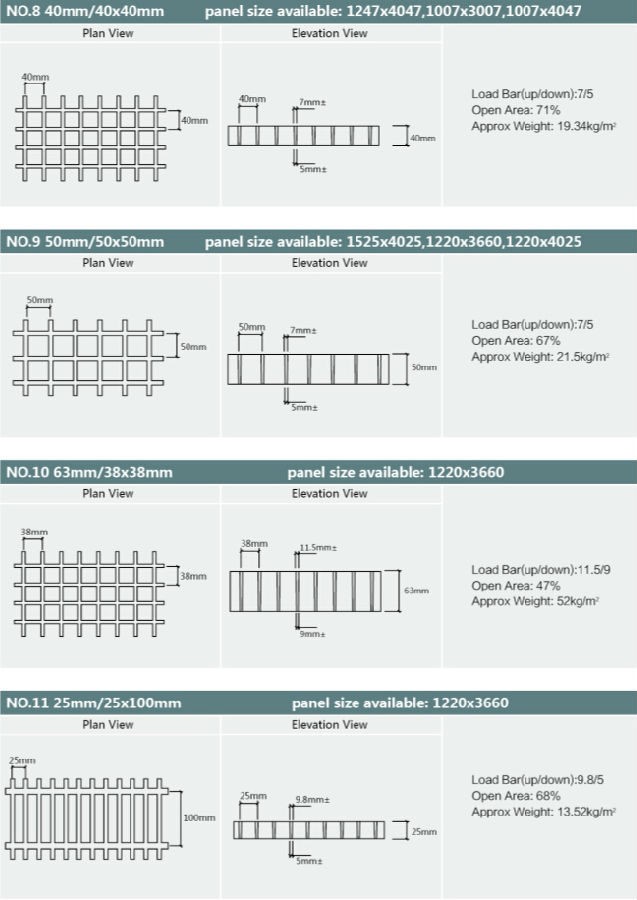

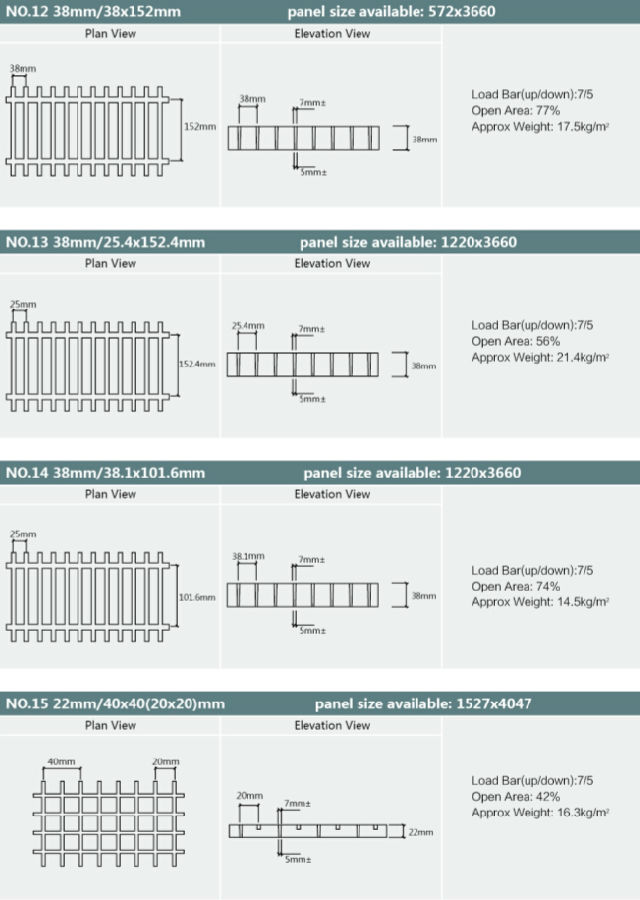

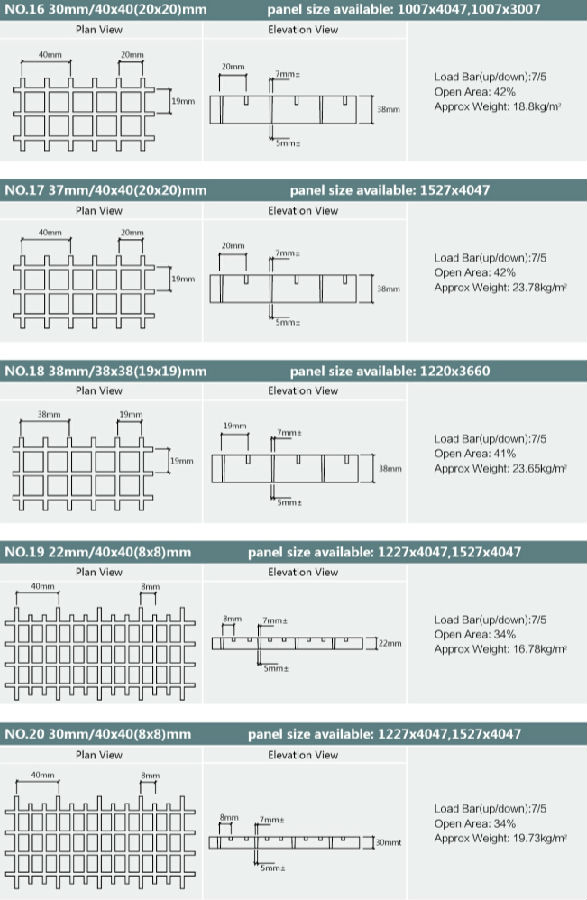

Moded Grating Sizes List:

- Q: What are the different types of FRP pultrusion profiles available?

- Some of the different types of FRP pultrusion profiles available include standard shapes such as I-beams, channels, angles, and tubes. Additionally, there are custom profiles that can be designed and manufactured based on specific project requirements.

- Q: Are FRP pultrusion profiles resistant to impact from heavy machinery?

- The high strength-to-weight ratio and excellent mechanical properties of FRP pultrusion profiles are well-known, making them resistant to various external impacts. However, their resistance to heavy machinery impacts depends on several factors. The impact resistance of FRP pultrusion profiles is determined by their design, composition, and reinforcement materials. Manufacturers use different materials like fiberglass, carbon fiber, or composites, which greatly affect the profiles' ability to withstand heavy machinery impacts. The thickness and overall dimensions of the FRP profiles also contribute to their impact resistance. Thicker profiles offer better resistance to impact loads than thinner ones. Additionally, profiles with reinforced sections or extra layers for structural integrity can further enhance their impact resistance. Considering the specific application and magnitude of impact from heavy machinery is crucial. While FRP pultrusion profiles can generally withstand moderate to high impacts, extreme forces or heavy machinery with substantial weight can still cause damage. In such cases, additional protective measures like impact-resistant coatings or metal inserts may be necessary. In conclusion, FRP pultrusion profiles demonstrate good resistance to impact from heavy machinery due to their inherent strength and durability. However, it is advisable to consult with the manufacturer or a structural engineer to ensure that the profiles meet the specific requirements of the application and machinery involved.

- Q: Can FRP pultrusion profiles be used in the construction of water treatment plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of water treatment plants. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them well-suited for water treatment plant applications. These profiles can be used in various structural components like beams, columns, grating, and handrails, providing a cost-effective and long-lasting solution for the construction of water treatment plants.

- Q: Are FRP pultrusion profiles resistant to termites or other pests?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are inherently resistant to termites and other pests. Unlike traditional wood or metal materials, FRP profiles do not provide a food source for termites or any other pests. FRP is composed of a combination of reinforced fibers and a polymer matrix, typically made of fiberglass and resin. These materials are not appealing to pests and do not provide any nutritional value, making FRP profiles highly resistant to termite damage or infestation. This resistance to pests is one of the many advantages of using FRP pultrusion profiles in various applications, especially in outdoor or humid environments where termites are commonly found.

- Q: Are FRP pultrusion profiles resistant to UV degradation?

- Yes, FRP pultrusion profiles are generally resistant to UV degradation. The combination of the materials used in pultrusion, such as fiberglass and resin, provides inherent UV resistance, making them suitable for outdoor applications where exposure to sunlight is a concern. However, it is always recommended to consult the manufacturer's specifications and guidelines to ensure optimal UV protection and longevity.

- Q: Are FRP pultrusion profiles resistant to hydrochloric acid?

- Yes, FRP pultrusion profiles are generally resistant to hydrochloric acid due to the corrosion-resistant properties of the fiberglass reinforcement and the resin matrix used in their construction. However, the specific resistance may vary depending on the composition and concentration of the acid, and it is recommended to consult the manufacturer's specifications for detailed information regarding chemical resistance.

- Q: Can FRP pultrusion profiles be used in the construction of railway platforms?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of railway platforms. FRP profiles are lightweight, durable, and corrosion-resistant, making them suitable for various structural applications. They offer high strength-to-weight ratio, reducing the load on the platform structure while maintaining structural integrity. Additionally, FRP profiles can be customized to meet specific design requirements, providing flexibility in creating efficient and long-lasting railway platforms.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of chemical reactors?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of chemical reactors. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent resistance to corrosion, high strength-to-weight ratio, and dimensional stability, making them ideal for use in chemical reactors. Additionally, FRP materials can withstand a wide range of chemical environments and temperatures, making them a reliable choice for this application.

- Q: Can FRP pultrusion profiles be used in the construction of pedestrian bridges?

- Yes, FRP pultrusion profiles can be used in the construction of pedestrian bridges. FRP pultrusion profiles offer several advantages such as high strength, corrosion resistance, low maintenance, and lightweight properties, making them suitable for pedestrian bridge applications. Additionally, the flexibility in design and customization options of FRP pultrusion profiles allows for efficient construction and installation of pedestrian bridges.

- Q: Are FRP pultrusion profiles resistant to seismic activity?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength-to-weight ratio and excellent mechanical properties. However, when it comes to seismic activity, their resistance depends on various factors. In general, FRP pultrusion profiles can exhibit good resistance to seismic activity due to their inherent properties. The composite materials used in their construction, such as fiberglass and resin, offer high tensile strength and stiffness, making them capable of withstanding dynamic loads caused by earthquakes. Moreover, FRP pultrusion profiles have been extensively tested and proven to possess excellent fatigue resistance. This property is crucial during seismic events as structures are subjected to repeated dynamic loading. The ability of FRP profiles to withstand cyclic loading without suffering from fatigue failure significantly enhances their seismic resistance compared to traditional materials like steel or concrete. Another advantage of FRP pultrusion profiles in seismic activity is their lightweight nature. Their low weight reduces the overall mass of the structure, resulting in lower seismic forces. This weight reduction can lead to reduced seismic responses and less damage during an earthquake. However, it is important to note that the seismic resistance of FRP pultrusion profiles can be influenced by various factors. These include the design and quality of the profiles, the connection details, and the overall structural system in which they are used. Proper engineering and design considerations must be taken into account to ensure optimal performance and seismic resistance. In conclusion, FRP pultrusion profiles have the potential to offer good resistance to seismic activity due to their high strength, stiffness, and fatigue resistance. However, their performance in seismic events depends on various factors, and careful design and engineering practices are essential to maximize their seismic resistance.

Send your message to us

FRP Pultrusion Profiles for Power Steel Paper Plant Grating Floor Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords