FRP Pultrusion Profiles for High Loaded Strength FRP Gratings in Power Plants

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

FRP molded grating made of vertical and horizontal continuous fiberglass fully soaked in unsaturated polyester resin giving perfect bi-directional mechanical properties. Combining unmatched corrosion resistance with strength, long life and safety, molded grating provide the ultimate in reliable performance, even in the most demanding corrosive conditions. Besides, it is easy to cut and install. CNBM offer the widest selection with panel sizes, colors and slip resistant surfaces, clients can avail FRP grating your specific requirements.

Product Features:

- Light but high loaded strength

- High anti-corrosion and anti-aging

- Easy installation and maintenance

- Low maintenance

- Non-conductive

- Lowest in life cycle cost

- Corrosion Resstance

- Anti-slippery

- Various sizes and color available

Colour Design:

To satisfy customer's design project, CNBM grating offers a wide selection of grating colors to choose from. The standard colors available for fiberglass grating as following:

- Blue

- Red

- Yellow

- Green

- Light Grey

- Dark Grey

Custom colors of fiberglass grating may be available upon request, you can contact us learn more.

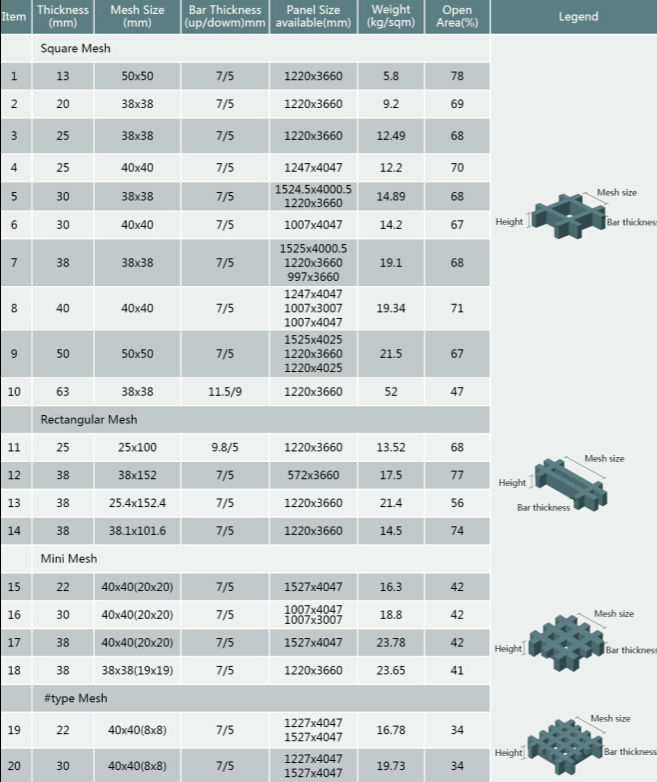

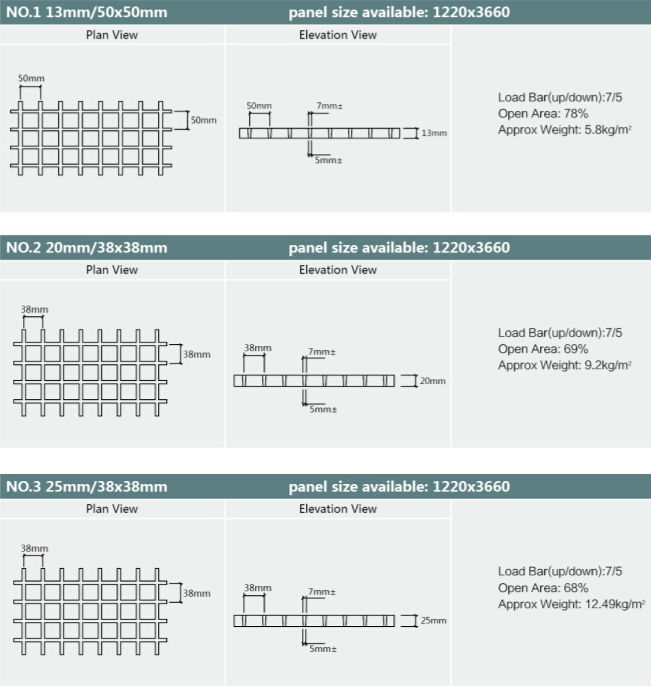

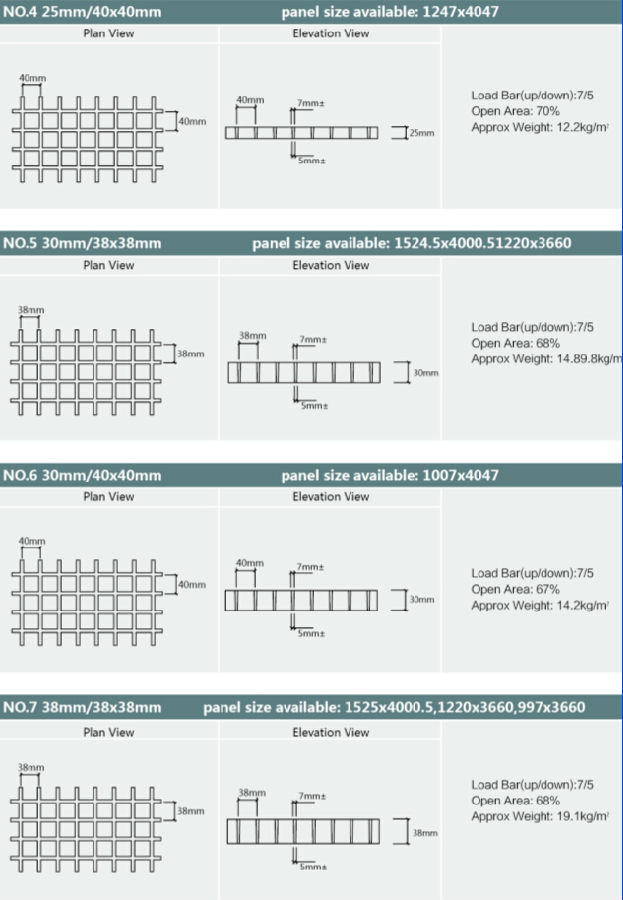

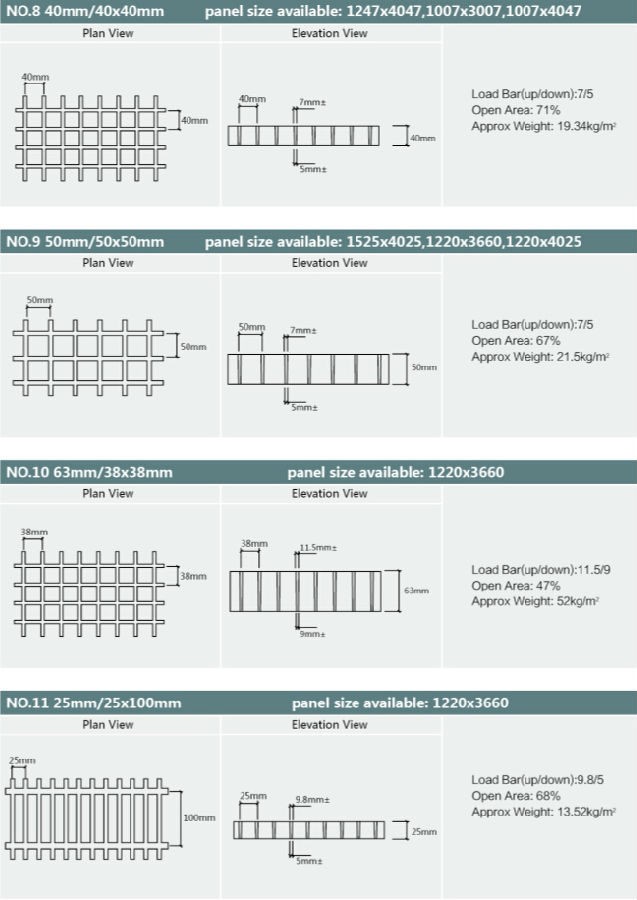

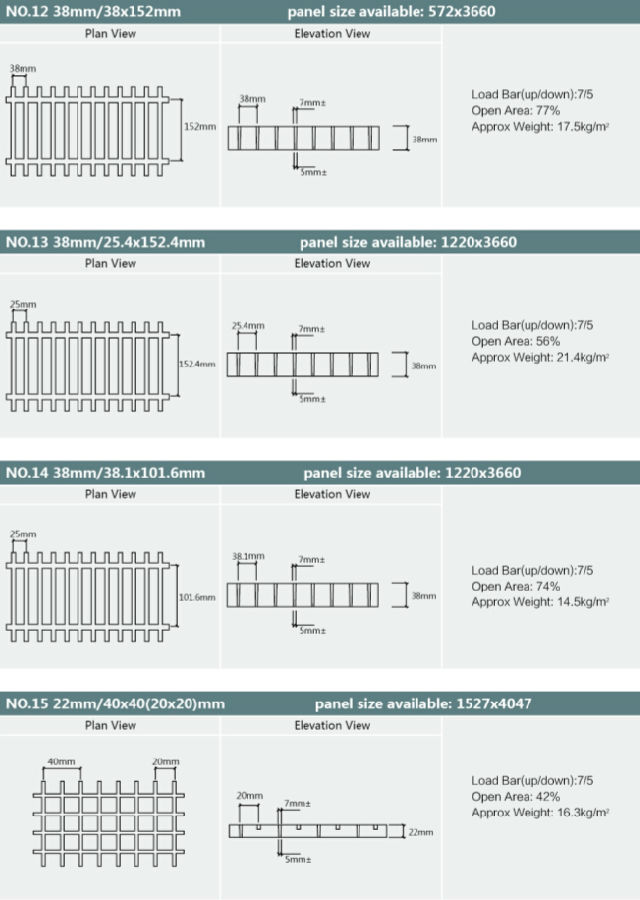

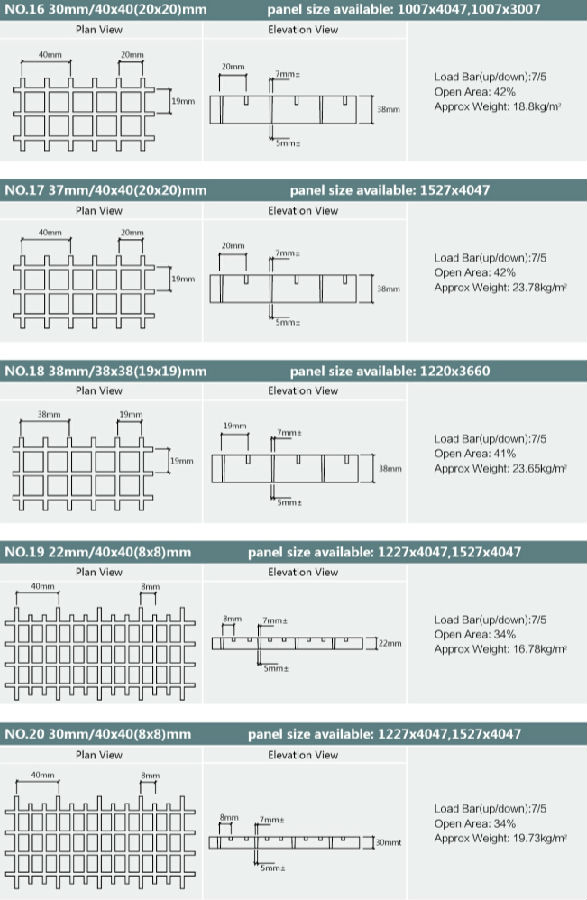

Moded Grating Sizes List:

- Q: Are FRP pultrusion profiles resistant to high winds or hurricanes?

- Yes, FRP pultrusion profiles are resistant to high winds and hurricanes. The inherent strength and durability of fiberglass reinforced plastic (FRP) combined with the pultrusion manufacturing process make these profiles highly resistant to extreme weather conditions, including high winds and hurricanes. They have been extensively tested and proven to withstand strong winds and turbulent weather events.

- Q: What are the typical dimensions and sizes of FRP pultrusion profiles?

- The dimensions and sizes of FRP pultrusion profiles may vary depending on the application and manufacturer. However, there are some common ranges to consider. Concerning dimensions, the length of FRP pultrusion profiles can range from a few feet to several tens of feet, depending on the project requirements. The width or height of the profiles can vary greatly depending on the intended use, but typical dimensions usually fall within 0.5 inches to 12 inches. The size of FRP pultrusion profiles is determined by their cross-sectional area, usually measured in square inches. The cross-section can take on various shapes, such as rectangular, square, round, or custom designs. Typical sizes of FRP pultrusion profiles can range from as small as 0.1 square inches to as large as 100 square inches or more. It's worth noting that manufacturers can create custom-made FRP pultrusion profiles to meet specific project requirements. They have the flexibility to produce profiles with unique dimensions and sizes, ensuring they align with the specific needs of the application. Therefore, it's advisable to consult with the manufacturer or supplier to determine the most suitable dimensions and sizes for a specific FRP pultrusion profile.

- Q: Are FRP pultrusion profiles resistant to impact from heavy machinery?

- The high strength-to-weight ratio and excellent mechanical properties of FRP pultrusion profiles are well-known, making them resistant to various external impacts. However, their resistance to heavy machinery impacts depends on several factors. The impact resistance of FRP pultrusion profiles is determined by their design, composition, and reinforcement materials. Manufacturers use different materials like fiberglass, carbon fiber, or composites, which greatly affect the profiles' ability to withstand heavy machinery impacts. The thickness and overall dimensions of the FRP profiles also contribute to their impact resistance. Thicker profiles offer better resistance to impact loads than thinner ones. Additionally, profiles with reinforced sections or extra layers for structural integrity can further enhance their impact resistance. Considering the specific application and magnitude of impact from heavy machinery is crucial. While FRP pultrusion profiles can generally withstand moderate to high impacts, extreme forces or heavy machinery with substantial weight can still cause damage. In such cases, additional protective measures like impact-resistant coatings or metal inserts may be necessary. In conclusion, FRP pultrusion profiles demonstrate good resistance to impact from heavy machinery due to their inherent strength and durability. However, it is advisable to consult with the manufacturer or a structural engineer to ensure that the profiles meet the specific requirements of the application and machinery involved.

- Q: Are FRP pultrusion profiles resistant to chemical spills or leaks?

- FRP pultrusion profiles are known for their high resistance to chemical spills or leaks, making them an excellent choice for construction projects. One of the main benefits of using FRP as a building material is its exceptional chemical resistance. These profiles are made by impregnating continuous fibers with a thermosetting resin, resulting in a durable composite material. The selection of the resin used in FRP pultrusion profiles depends on the specific chemical environment they will be exposed to. This allows for customization and optimization of the composite's ability to withstand different chemicals. Additionally, the fibers used in FRP are typically chemically inert, further enhancing the profiles' resistance to chemical spills or leaks. FRP pultrusion profiles have proven to be highly resistant to a wide range of chemicals, including acids, alkalis, solvents, and corrosive substances. They are commonly used in industries such as chemical processing, water and wastewater treatment, oil and gas, and marine applications, where exposure to aggressive chemicals is common. Apart from their chemical resistance, FRP pultrusion profiles offer several other advantages. They are lightweight yet strong and stiff, making them ideal for applications that require structural integrity. They are also non-conductive, non-magnetic, and have excellent electrical insulation properties. Overall, FRP pultrusion profiles are a reliable option for environments where chemical spills or leaks are a concern. They provide robust resistance to a wide variety of chemicals, ensuring long-lasting performance and minimal maintenance requirements.

- Q: Can FRP pultrusion profiles be used in the oil and gas industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the oil and gas industry. These profiles offer excellent corrosion resistance, high strength-to-weight ratio, and low maintenance requirements, making them suitable for various applications in the industry such as pipe supports, cable trays, handrails, and platforms. Additionally, FRP pultrusion profiles are non-conductive, non-magnetic, and possess good fire-retardant properties, making them a safer alternative to traditional materials in hazardous environments.

- Q: Are FRP pultrusion profiles resistant to oils and greases?

- FRP pultrusion profiles have a general resistance to oils and greases. This resistance is due to their composition of fiberglass and resin materials, which naturally resist various chemicals, including oils and greases. The pultrusion process typically involves using a thermosetting resin, such as polyester or vinyl ester, which further enhances the profiles' ability to withstand chemical damage. Moreover, the fiberglass reinforcement adds durability and strength to the profiles, making them suitable for applications where exposure to oils and greases is expected. It is important to note, however, that the level of resistance to oils and greases may differ depending on the specific resin used and the chemical composition of the oils or greases. Therefore, it is advisable to seek detailed information from the manufacturer or supplier regarding the compatibility of FRP pultrusion profiles with specific oils and greases.

- Q: Can FRP pultrusion profiles be used in high-voltage applications?

- Yes, FRP pultrusion profiles can be used in high-voltage applications. FRP (Fiber Reinforced Polymer) materials are known for their excellent electrical insulation properties, making them suitable for high-voltage environments. Additionally, FRP pultrusion profiles offer advantages such as high strength, corrosion resistance, and lightweight, making them a viable option for high-voltage applications.

- Q: Are FRP pultrusion profiles resistant to graffiti?

- FRP pultrusion profiles are generally resistant to graffiti due to their unique characteristics and composition. Pultruded fiberglass reinforced plastic (FRP) profiles are manufactured using a combination of high-strength fibers and a polymer resin matrix, resulting in a highly durable and robust material. One of the key advantages of FRP profiles is their excellent resistance to various forms of corrosion, including chemical, moisture, and UV resistance. These properties make FRP profiles less susceptible to the damaging effects of graffiti. Unlike traditional materials such as wood or metal, FRP pultrusion profiles do not provide a porous surface that allows paint or markers to penetrate and adhere easily. Additionally, FRP profiles are often produced with a smooth and non-porous finish, further deterring the attachment of graffiti. Even if graffiti is applied to the surface, it can be easily removed using non-abrasive cleaning methods without causing any damage to the profile's structural integrity or appearance. However, it is important to note that no material is completely immune to graffiti. Determined vandals may still find ways to leave marks on FRP profiles using specialized graffiti materials or techniques. Nonetheless, the resistance of FRP pultrusion profiles to graffiti is significantly higher compared to many other conventional materials, making them an ideal choice for areas prone to vandalism or graffiti attacks.

- Q: Can FRP pultrusion profiles be used in mining applications?

- Mining applications can utilize FRP pultrusion profiles, which are known for their high strength-to-weight ratio, durability, and corrosion resistance. These profiles are suitable for a range of purposes in mining operations. They can provide structural support in underground mines, including the construction of tunnels, shafts, and mine roofs. Their strength allows them to handle heavy loads and provide long-term support. Additionally, FRP pultrusion profiles can support equipment and machinery like conveyor systems, pumps, and tanks. Their corrosion resistance makes them ideal for use in harsh mining environments that involve exposure to moisture, chemicals, and abrasive materials. Moreover, FRP pultrusion profiles can be used for safety applications in mining, such as handrails, walkways, and grating systems. These profiles offer reliable and non-slip surfaces, ensuring the safety of mining workers. In summary, FRP pultrusion profiles bring several advantages to mining applications, including high strength, corrosion resistance, durability, and easy installation. These qualities make them a cost-effective and viable option for various mining operations, enhancing efficiency and safety in the industry.

- Q: What are the mechanical properties of FRP pultrusion profiles?

- FRP (Fiber Reinforced Polymer) pultrusion profiles possess several desirable mechanical properties that make them a popular choice in various industries. Some of the key mechanical properties of FRP pultrusion profiles include: 1. High Strength: FRP pultrusion profiles exhibit exceptional tensile and flexural strength, making them suitable for applications requiring load-bearing capabilities. The reinforcing fibers, such as carbon, glass, or aramid, provide the profiles with superior strength-to-weight ratios compared to traditional materials like steel or aluminum. 2. Lightweight: FRP pultrusion profiles are significantly lighter than metals, resulting in reduced transportation and installation costs. The low weight also makes them easier to handle and manipulate during construction or manufacturing processes. 3. Corrosion Resistance: Unlike metals, FRP pultrusion profiles are inherently corrosion-resistant. They do not rust, corrode, or degrade when exposed to harsh environments, including moisture, chemicals, or UV radiation. This property makes them ideal for applications in marine, chemical, and infrastructure industries. 4. Dimensional Stability: FRP pultrusion profiles offer excellent dimensional stability, meaning they retain their shape and size even under extreme temperature variations. They have minimal thermal expansion and contraction rates, ensuring long-term structural integrity. 5. Electrical Non-Conductivity: FRP profiles are non-conductive and possess excellent electrical insulation properties. This property is crucial in applications where electrical conductivity must be avoided, such as in electrical enclosures or infrastructure near power lines. 6. Design Flexibility: FRP pultrusion profiles can be manufactured in various complex shapes and sizes, allowing for customized designs to meet specific application requirements. They can be easily molded or formed during the manufacturing process, making them adaptable to diverse project needs. 7. Impact Resistance: FRP pultrusion profiles exhibit good impact resistance, absorbing and dispersing energy when subjected to mechanical loads. This property ensures durability and structural integrity, making them suitable for applications prone to impact or dynamic loading, such as construction, transportation, or sporting equipment. Overall, the mechanical properties of FRP pultrusion profiles make them an attractive alternative to traditional materials in a wide range of industries, offering strength, durability, and corrosion resistance while being lightweight and easy to work with.

Send your message to us

FRP Pultrusion Profiles for High Loaded Strength FRP Gratings in Power Plants

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords