FRP Pultrusion Profiles for Big Plant and Big Industry FRP Gratings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

FRP molded grating made of vertical and horizontal continuous fiberglass fully soaked in unsaturated polyester resin giving perfect bi-directional mechanical properties. Combining unmatched corrosion resistance with strength, long life and safety, molded grating provide the ultimate in reliable performance, even in the most demanding corrosive conditions. Besides, it is easy to cut and install. CNBM offer the widest selection with panel sizes, colors and slip resistant surfaces, clients can avail FRP grating your specific requirements.

Product Features:

- Light but high loaded strength

- High anti-corrosion and anti-aging

- Easy installation and maintenance

- Low maintenance

- Non-conductive

- Lowest in life cycle cost

- Corrosion Resstance

- Anti-slippery

- Various sizes and color available

Colour Design:

To satisfy customer's design project, CNBM grating offers a wide selection of grating colors to choose from. The standard colors available for fiberglass grating as following:

- Blue

- Red

- Yellow

- Green

- Light Grey

- Dark Grey

Custom colors of fiberglass grating may be available upon request, you can contact us learn more.

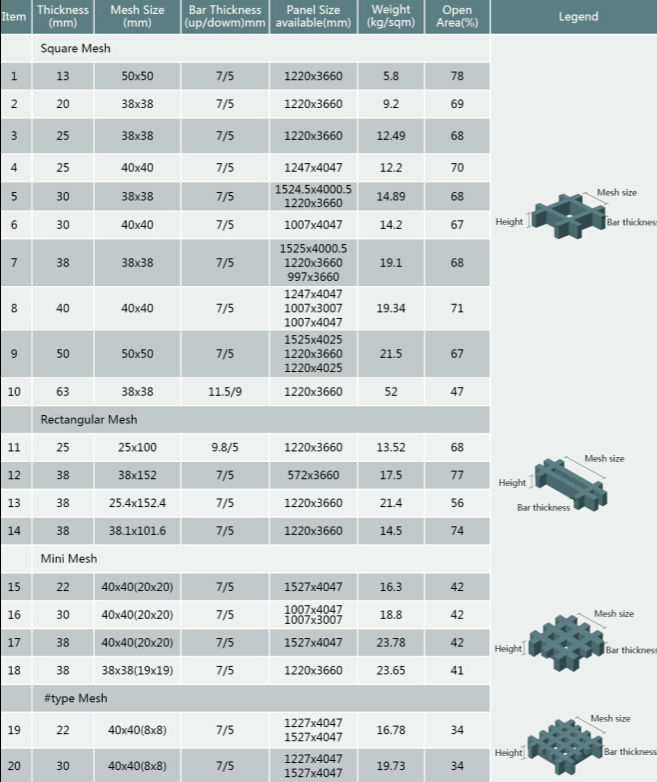

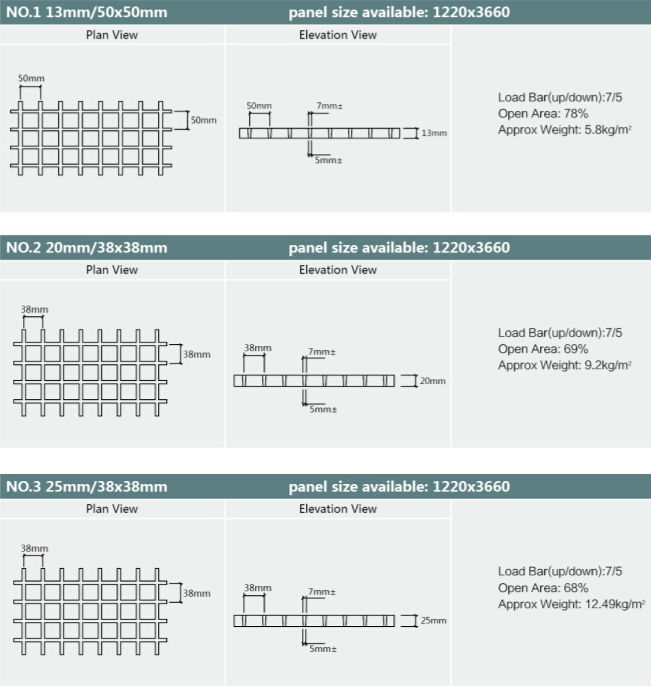

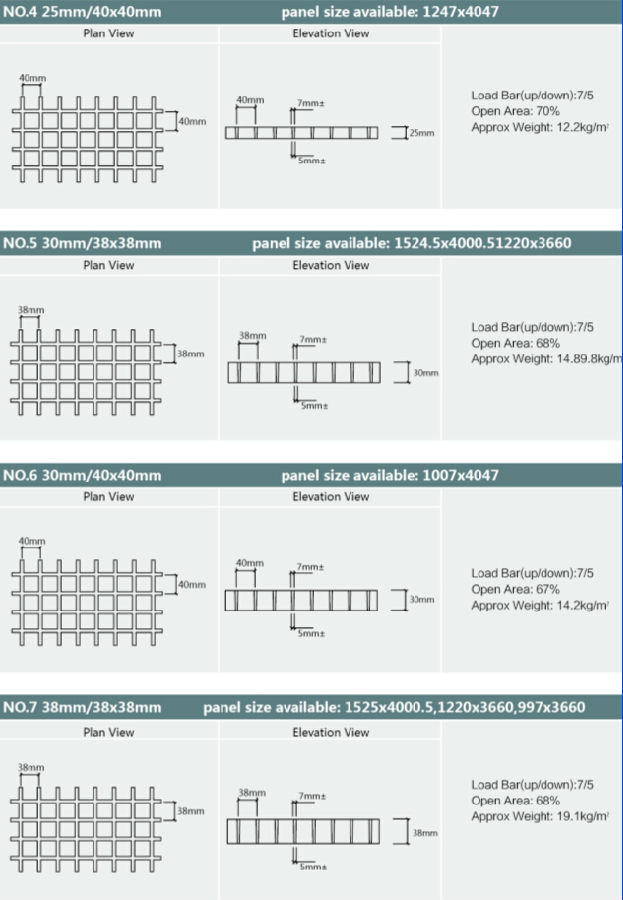

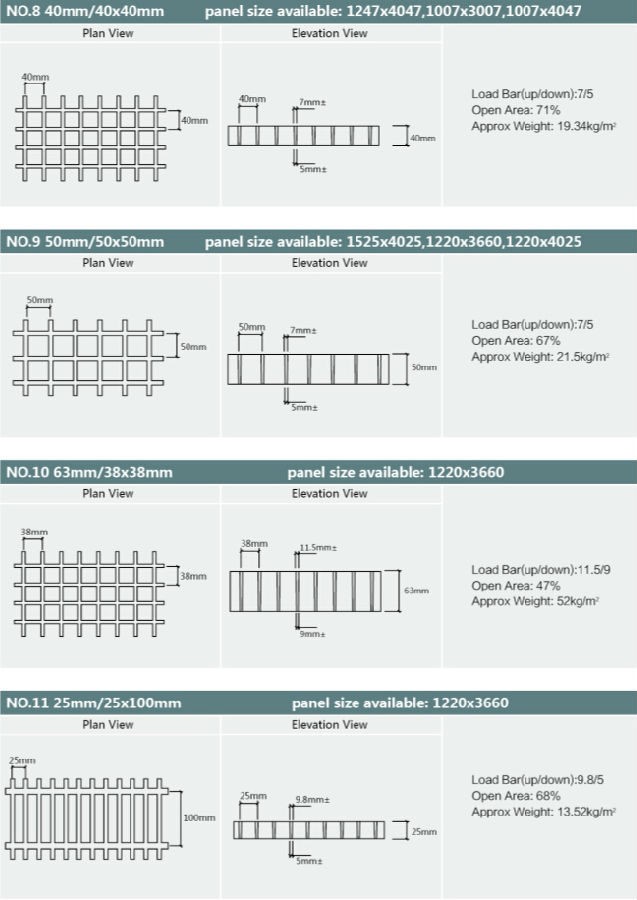

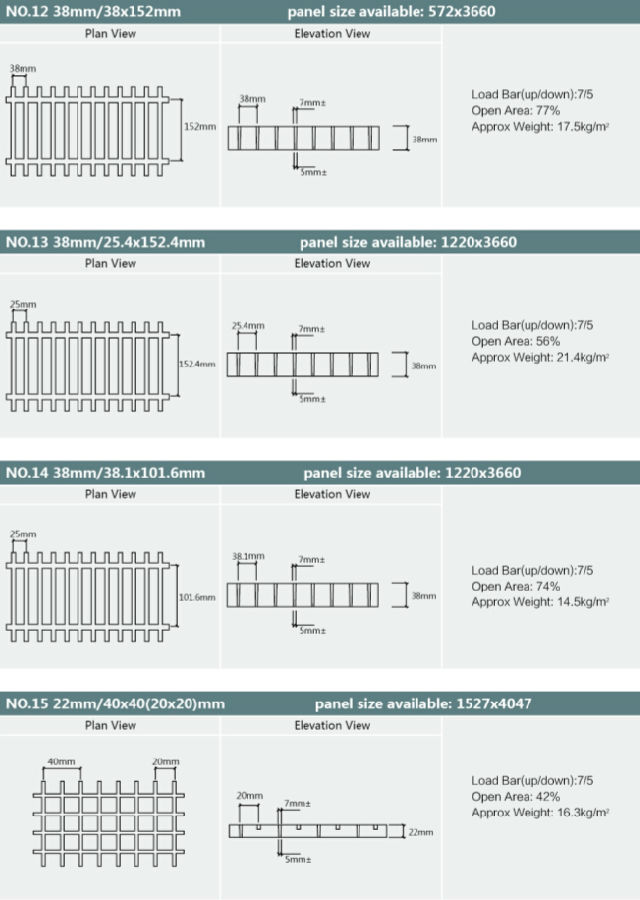

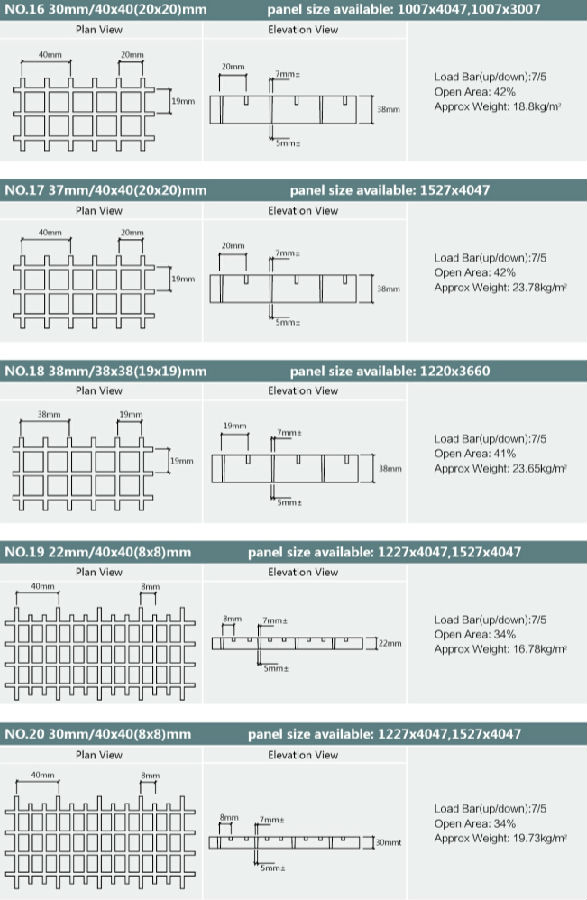

Moded Grating Sizes List:

- Q: What is the impact resistance of FRP pultrusion profiles?

- FRP pultrusion profiles exhibit a remarkably high level of impact resistance. These profiles are produced by pulling reinforcing fibers, such as fiberglass, through a resin bath and then into a heated die, where the resin solidifies and cures. This manufacturing technique generates a durable and robust composite material with exceptional mechanical properties, including impact resistance. The impact resistance of FRP pultrusion profiles may differ depending on the specific formulation, design, and orientation of the reinforcing fibers employed. Nevertheless, in general, FRP pultrusion profiles have been proven to possess superior impact resistance when compared to traditional materials like steel or aluminum. The combination of reinforcing fibers and the resin matrix in FRP pultrusion profiles provides enhanced strength and toughness, enabling the profiles to withstand substantial impact loads without cracking, breaking, or deforming. Consequently, these profiles are highly suitable for a diverse range of applications where impact resistance is of utmost importance, such as in construction, transportation, and sporting goods. Furthermore, the impact resistance of FRP pultrusion profiles can be customized by adjusting factors such as fiber content, fiber orientation, and resin type during the manufacturing process. This allows for tailored profiles that meet specific application requirements. In summary, FRP pultrusion profiles deliver outstanding impact resistance due to the integration of reinforcing fibers and resin matrix. Their exceptional strength, toughness, and ability to endure impact loads make them a dependable choice across various industries and applications.

- Q: Are FRP pultrusion profiles electrically conductive?

- FRP pultrusion profiles are typically not electrically conductive. This is because they are made using a combination of fiberglass reinforcement and a thermosetting resin matrix, which provide excellent insulation properties. The fiberglass reinforcement is inherently non-conductive, while the resin matrix further enhances this property. Therefore, FRP pultrusion profiles are commonly used in applications where electrical conductivity is not desired or poses a safety risk. However, it is important to note that certain modifications or additions can be made to the pultrusion process to introduce electrical conductivity if required for specific applications.

- Q: Can FRP pultrusion profiles be used in the construction of elevated walkways?

- Yes, FRP pultrusion profiles can be used in the construction of elevated walkways. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various construction applications including elevated walkways. They are lightweight, yet strong enough to support pedestrian traffic and withstand environmental conditions. Additionally, FRP pultrusion profiles can be easily customized to meet specific design requirements, making them a popular choice in the construction industry.

- Q: Are FRP pultrusion profiles resistant to hydrochloric acid?

- FRP pultrusion profiles exhibit a general resistance to hydrochloric acid. The corrosion resistance of FRP materials varies based on the specific resin and fiber used during manufacturing. Nevertheless, most FRP pultrusion profiles are designed to endure exposure to a wide array of chemicals, including hydrochloric acid. The corrosion resistance of FRP is attributed to the chemical inertness of the resin matrix, typically composed of polyester, vinyl ester, or epoxy. These resins form a protective barrier against chemical attack, allowing FRP profiles to maintain their structural integrity even in harsh surroundings. However, the level of resistance may fluctuate depending on the concentration and temperature of the hydrochloric acid. In instances of high concentration or elevated temperatures, the resistance may diminish. It is always recommended to refer to the manufacturer's specifications or seek expert advice to ensure the suitability of FRP pultrusion profiles for specific acid concentrations and temperature ranges. In conclusion, FRP pultrusion profiles are renowned for their exceptional chemical resistance and are frequently selected for applications involving exposure to acids or corrosive environments.

- Q: Are FRP pultrusion profiles impact resistant?

- FRP pultrusion profiles are widely recognized for their exceptional impact resistance. By combining reinforcing fibers like glass or carbon with a polymer matrix, they become intrinsically sturdy and long-lasting. The pultrusion process further bolsters their impact resistance by aligning the fibers in the direction of the load, providing optimal strength against impacts. Additionally, these profiles boast a remarkable strength-to-weight ratio, enabling them to withstand heavy impacts without significant damage or deformation. This characteristic makes them ideal for industries like construction, transportation, and infrastructure, where impact resistance is vital. Furthermore, FRP pultrusion profiles exhibit outstanding resistance to corrosion, chemicals, and UV radiation, enhancing their durability and long-term performance. Even in harsh environments, they maintain their impact resistance properties, making them the preferred choice for various sectors. Nonetheless, it is crucial to acknowledge that the impact resistance of FRP pultrusion profiles can vary depending on factors like design, composition, and manufacturing process. To ensure the profiles meet the desired impact resistance requirements for a specific application, it is advisable to consult with the manufacturer or supplier.

- Q: Can FRP pultrusion profiles be used in the automotive manufacturing industry?

- Certainly! Fiber Reinforced Polymer (FRP) pultrusion profiles have the potential to be utilized within the automotive manufacturing sector. These profiles possess a number of advantages that render them appropriate for automotive applications. To begin with, one of the key benefits of FRP profiles is their lightweight nature, which aids in reducing the overall weight of vehicles. This is of utmost importance in enhancing fuel efficiency and decreasing emissions. Moreover, the reduced weight of FRP profiles enables improved handling and enhanced performance. Additionally, FRP profiles exhibit exceptional mechanical properties, including high strength and stiffness. These properties make them well-suited for integration into structural components of vehicles, such as chassis, body panels, and frames. FRP profiles are able to withstand heavy loads and offer excellent impact resistance, thereby ensuring the safety of both the vehicle and its occupants. Furthermore, FRP profiles possess outstanding corrosion resistance, a quality that is particularly advantageous in automotive applications. In contrast to traditional materials like steel, FRP profiles are impervious to rust and corrosion. Consequently, they are ideally suited for deployment in various automotive environments, including those that involve exposure to moisture, chemicals, and salt. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements, thereby affording flexibility in the manufacturing process. They can be produced in a range of shapes and sizes, which allows for the design of intricate components. This design flexibility also permits customization and optimization of vehicle performance. Lastly, FRP profiles possess excellent thermal and electrical insulation properties. This renders them appropriate for applications where minimizing electrical conductivity or providing thermal insulation is necessary. On the whole, the combination of the lightweight nature, high strength, corrosion resistance, design flexibility, and insulation properties of FRP pultrusion profiles positions them as an ideal choice for deployment within the automotive manufacturing industry. Their usage can contribute to the development of more efficient, safe, and durable vehicles.

- Q: Can FRP pultrusion profiles be used in chemical storage tanks?

- Indeed, it is possible to utilize FRP pultrusion profiles in the construction of chemical storage tanks. These profiles are recognized for their exceptional resistance to corrosion, rendering them suitable for the storage of a wide array of chemicals. Moreover, their lightweight nature, strength, and impressive strength-to-weight ratio make them an optimal choice for the creation of robust and long-lasting chemical storage tanks. Furthermore, FRP pultrusion profiles can be tailor-made to fulfill specific design requirements, enabling flexibility in tank design and construction. In summary, due to their corrosion resistance, strength, and customization capabilities, FRP pultrusion profiles emerge as a dependable and cost-efficient alternative for chemical storage tanks.

- Q: Can FRP pultrusion profiles be used in chemical processing plants?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in chemical processing plants. FRP pultrusion profiles offer excellent corrosion resistance, making them suitable for chemical environments where exposure to different chemicals, acids, and bases is common. Additionally, FRP pultrusion profiles are lightweight, yet strong, and can be fabricated to meet specific design requirements, making them versatile for various applications within a chemical processing plant. They are also electrically non-conductive, which is beneficial in environments where electrical insulation is necessary. Overall, FRP pultrusion profiles provide a durable and cost-effective solution for chemical processing plants, offering long-term performance and reducing maintenance costs.

- Q: How do FRP pultrusion profiles compare to traditional building materials?

- FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages over traditional building materials. Firstly, FRP profiles are extremely lightweight yet highly durable, making them ideal for applications where weight reduction is critical, such as in aerospace or automotive industries. In contrast, traditional materials like steel or wood are much heavier and may require additional support or reinforcement. Another key advantage of FRP pultrusion profiles is their exceptional strength-to-weight ratio. They possess high tensile and flexural strength, surpassing that of many traditional materials. This strength allows FRP profiles to provide excellent structural support while minimizing the overall weight of the structure. Furthermore, FRP pultrusion profiles are corrosion-resistant, making them suitable for environments prone to moisture, chemicals, or extreme temperatures. Unlike steel or wood, FRP does not rust or rot, hence requiring minimal maintenance and extending the lifespan of the structure. In terms of design flexibility, FRP profiles offer a wide range of shapes and sizes, enabling architects and engineers to create complex and intricate structures. Traditional materials often have limitations in terms of design possibilities and may require additional fabrication steps to achieve the desired shape. Additionally, FRP pultrusion profiles are electrically non-conductive, making them an ideal choice for applications where electrical insulation is required. Unlike metals, FRP does not conduct electricity, reducing the risk of electrical accidents. Lastly, FRP profiles are environmentally friendly as they can be made from recycled materials and are fully recyclable themselves. In contrast, traditional materials like steel or concrete require significant energy consumption and contribute to carbon emissions during their production. Overall, FRP pultrusion profiles offer numerous advantages over traditional building materials, including lightweight, high strength, corrosion resistance, design flexibility, electrical insulation, and environmental sustainability. These benefits make FRP profiles a compelling choice for a wide range of industries and applications.

- Q: Can FRP pultrusion profiles be used in the construction of pedestrian bridges?

- Pedestrian bridges can utilize FRP pultrusion profiles, which offer numerous advantages for bridge construction. Firstly, these profiles are lightweight yet incredibly strong and durable, making them ideal for weight-sensitive pedestrian bridges. The lightweight nature of FRP profiles also simplifies transportation and installation, resulting in cost savings. Secondly, FRP pultrusion profiles are corrosion-resistant, a critical factor in bridge construction. Unlike traditional materials such as steel or concrete, FRP does not rust or corrode, even in harsh environments. This property significantly prolongs the lifespan of pedestrian bridges while reducing maintenance costs. Moreover, FRP pultrusion profiles provide design flexibility. They can easily be tailored to meet specific project requirements, allowing for the creation of unique and innovative bridge designs. The material can be molded into various shapes and sizes, enabling the construction of aesthetically pleasing pedestrian bridges. Furthermore, FRP pultrusion profiles possess excellent mechanical properties, including a high strength-to-weight ratio and fatigue resistance. This ensures that the bridge can withstand the loads and stresses imposed by pedestrian traffic over an extended period. Lastly, FRP pultrusion profiles are non-conductive, making them a safe choice for pedestrian bridges. In areas where there are overhead power lines or electrical equipment, the non-conductive nature of FRP reduces the risk of electrical accidents. In conclusion, FRP pultrusion profiles are a suitable option for constructing pedestrian bridges due to their lightweight, corrosion-resistant, customizable, and mechanically strong properties. Their usage can result in durable, low-maintenance, and visually appealing bridges that provide a safe and efficient means of pedestrian transportation.

Send your message to us

FRP Pultrusion Profiles for Big Plant and Big Industry FRP Gratings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords