FRP Pultrusion Profiles for Anti-Corrosion in Big Plants and Industries

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

FRP molded grating made of vertical and horizontal continuous fiberglass fully soaked in unsaturated polyester resin giving perfect bi-directional mechanical properties. Combining unmatched corrosion resistance with strength, long life and safety, molded grating provide the ultimate in reliable performance, even in the most demanding corrosive conditions. Besides, it is easy to cut and install. CNBM offer the widest selection with panel sizes, colors and slip resistant surfaces, clients can avail FRP grating your specific requirements.

Product Features:

- Light but high loaded strength

- High anti-corrosion and anti-aging

- Easy installation and maintenance

- Low maintenance

- Non-conductive

- Lowest in life cycle cost

- Corrosion Resstance

- Anti-slippery

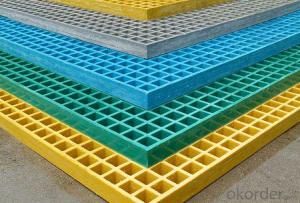

- Various sizes and color available

Colour Design:

To satisfy customer's design project, CNBM grating offers a wide selection of grating colors to choose from. The standard colors available for fiberglass grating as following:

- Blue

- Red

- Yellow

- Green

- Light Grey

- Dark Grey

Custom colors of fiberglass grating may be available upon request, you can contact us learn more.

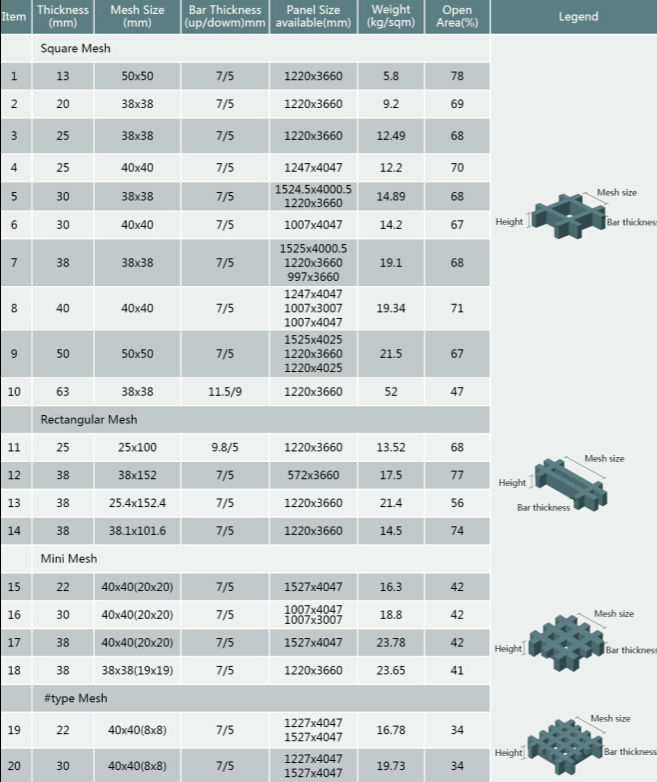

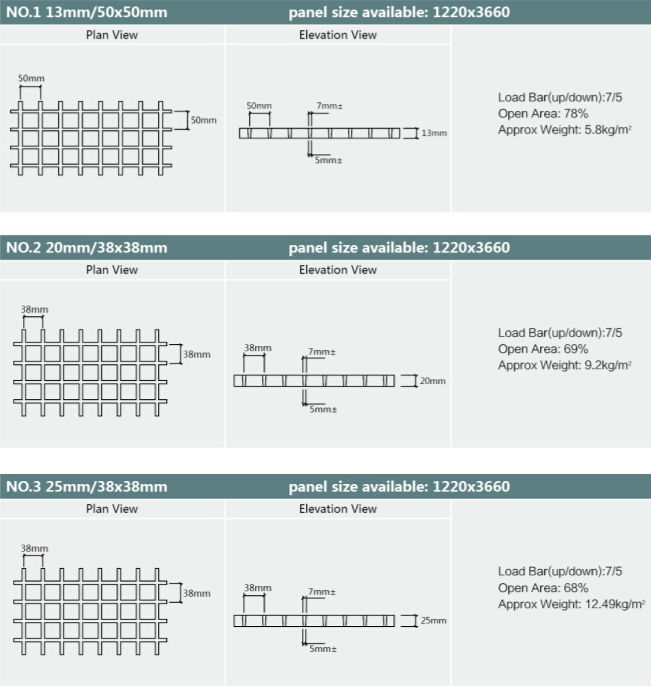

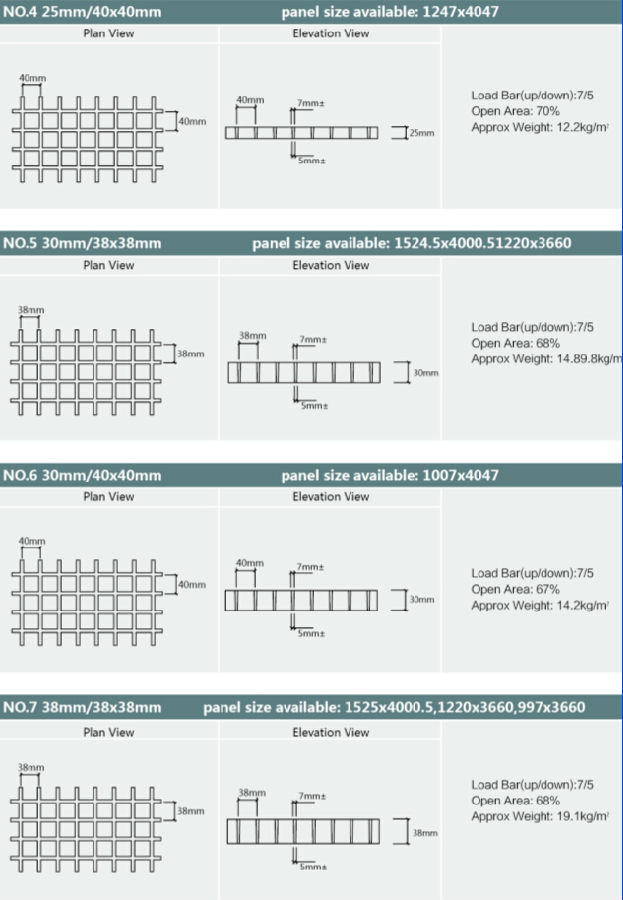

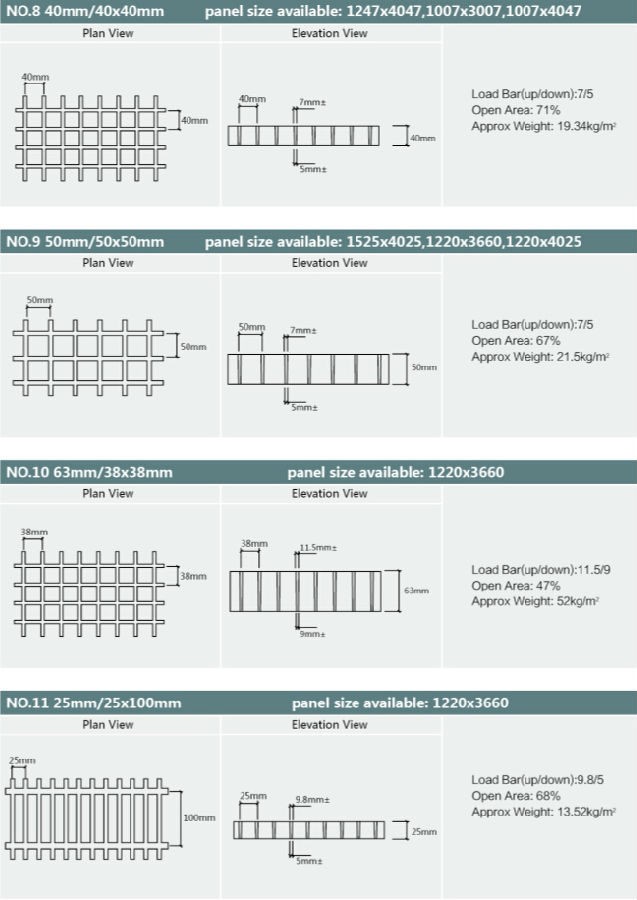

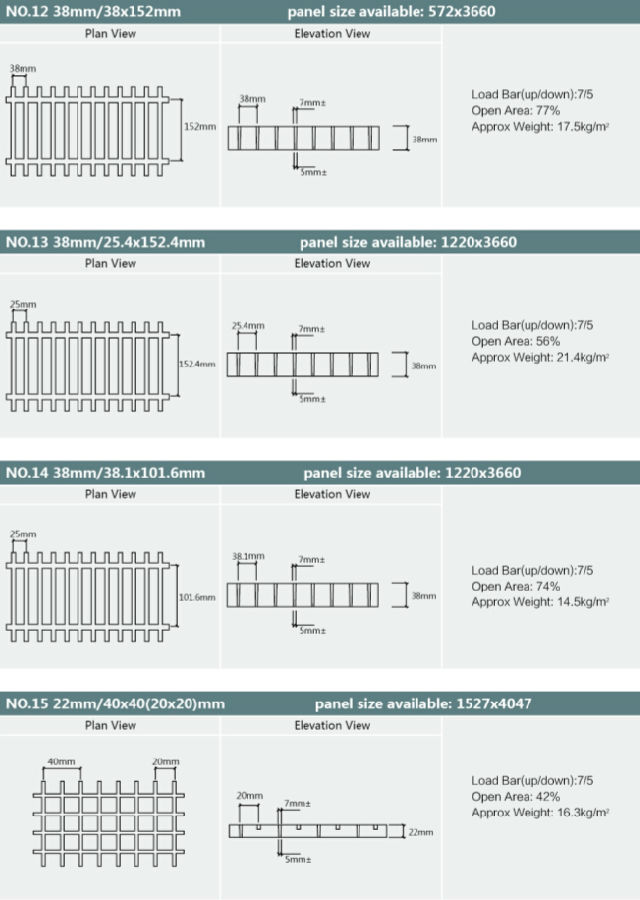

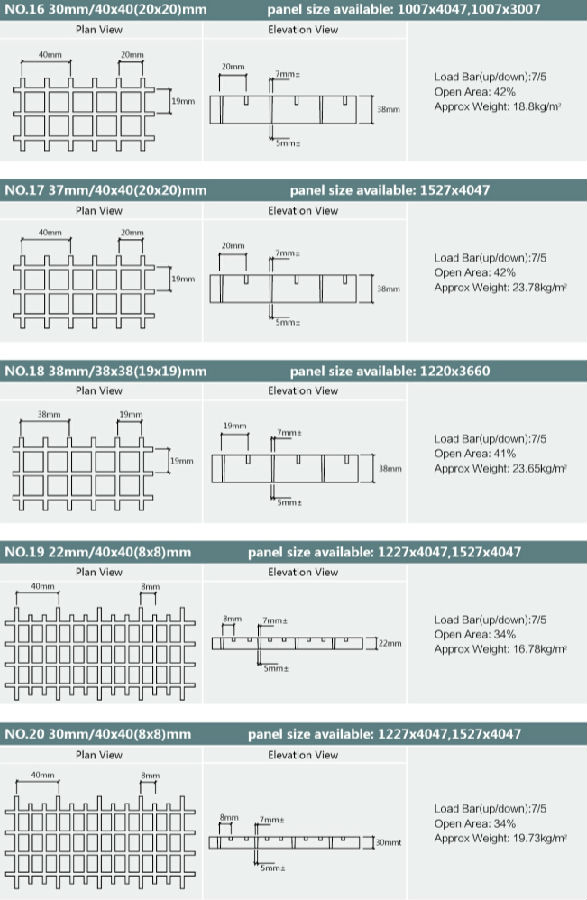

Moded Grating Sizes List:

- Q: Can FRP pultrusion profiles be used in the renewable energy sector?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the renewable energy sector. These profiles possess excellent strength-to-weight ratio, corrosion resistance, and durability, making them ideal for various renewable energy applications. They can be utilized in the manufacturing of wind turbine blades, solar panel frames, structural components for hydroelectric power systems, and much more. Additionally, FRP pultrusion profiles offer design flexibility, allowing for customization to specific project requirements.

- Q: What are the typical dimensions and sizes of FRP pultrusion profiles?

- The dimensions and sizes of FRP pultrusion profiles may vary depending on the application and manufacturer. However, there are some common ranges to consider. Concerning dimensions, the length of FRP pultrusion profiles can range from a few feet to several tens of feet, depending on the project requirements. The width or height of the profiles can vary greatly depending on the intended use, but typical dimensions usually fall within 0.5 inches to 12 inches. The size of FRP pultrusion profiles is determined by their cross-sectional area, usually measured in square inches. The cross-section can take on various shapes, such as rectangular, square, round, or custom designs. Typical sizes of FRP pultrusion profiles can range from as small as 0.1 square inches to as large as 100 square inches or more. It's worth noting that manufacturers can create custom-made FRP pultrusion profiles to meet specific project requirements. They have the flexibility to produce profiles with unique dimensions and sizes, ensuring they align with the specific needs of the application. Therefore, it's advisable to consult with the manufacturer or supplier to determine the most suitable dimensions and sizes for a specific FRP pultrusion profile.

- Q: Can FRP pultrusion profiles be used in the construction of safety barriers?

- Yes, FRP pultrusion profiles can be used in the construction of safety barriers. FRP (Fiber Reinforced Polymer) pultrusion profiles offer high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for safety barrier applications. They can withstand harsh environmental conditions and provide excellent impact resistance, making them an ideal choice for ensuring safety in various industries such as construction, transportation, and infrastructure.

- Q: Can FRP profiles replace carbon steel profiles?

- It can not be used as a cable carrier, but it can not replace the carbon steel profile. The general pultrusion section is connected with the connecting plate

- Q: Are FRP pultrusion profiles resistant to chemicals used in food packaging?

- Yes, FRP pultrusion profiles are generally resistant to the chemicals commonly used in food packaging. The combination of fiberglass reinforcement and resin matrix used in FRP profiles provides excellent chemical resistance, making them a suitable choice for applications involving contact with food packaging chemicals. However, it is always recommended to consult with the manufacturer or supplier to ensure specific compatibility with the chemicals involved.

- Q: Can FRP pultrusion profiles be used in the agricultural and farming industry?

- Yes, FRP pultrusion profiles can certainly be used in the agricultural and farming industry. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength, durability, and resistance to corrosion, making them ideal for outdoor and harsh environments such as those found in the agricultural and farming industry. These profiles can be used for various applications in agriculture and farming, including: 1. Fencing and enclosures: FRP pultrusion profiles can be used to create sturdy and long-lasting fences, gates, and enclosures for livestock and crop protection. The profiles are resistant to rot, rust, and insect damage, providing a reliable barrier for animals and crops. 2. Structural components: FRP pultrusion profiles can be used as structural components in agricultural buildings, sheds, and greenhouses. Their high strength-to-weight ratio allows for the construction of lightweight and durable structures that can withstand extreme weather conditions. 3. Irrigation systems: FRP pultrusion profiles can be used in the construction of irrigation systems, such as pipes, channels, and culverts. These profiles are non-corrosive and have a smooth interior surface, reducing friction and improving water flow efficiency. 4. Equipment support and framing: FRP pultrusion profiles can be used to provide support and framing for various agricultural equipment, such as conveyors, platforms, and machinery. Their high strength and stiffness make them suitable for heavy-duty applications. 5. Animal housing and equipment: FRP pultrusion profiles can be used to construct animal housing and equipment, such as pens, stalls, and feeding troughs. These profiles are resistant to chemicals, moisture, and UV radiation, ensuring a long lifespan and low maintenance requirements. In summary, FRP pultrusion profiles can be successfully utilized in the agricultural and farming industry due to their excellent mechanical properties, resistance to environmental factors, and versatility in various applications.

- Q: Are FRP pultrusion profiles resistant to electrical surges or lightning strikes?

- FRP pultrusion profiles are inherently non-conductive materials, which means they do not conduct electricity. Therefore, they can provide some level of resistance to electrical surges or lightning strikes. However, it is important to note that the level of resistance may vary depending on the specific composition and thickness of the FRP profiles. In high-risk areas prone to lightning strikes, additional measures may be necessary to ensure proper protection against electrical surges.

- Q: Are FRP pultrusion profiles fire resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are fire resistant. The combination of the reinforcing fibers and the polymer matrix used in FRP pultrusion profiles provide them with excellent fire resistance properties. These profiles are manufactured using a process known as pultrusion, which involves impregnating reinforcing fibers such as fiberglass or carbon fiber with a thermosetting resin. This resin undergoes a curing process, resulting in a strong and durable composite material. One of the key advantages of FRP pultrusion profiles is their inherent fire resistance. The thermosetting resin used in the manufacturing process has properties that make it highly resistant to fire. When exposed to flames or high temperatures, the resin does not melt or burn easily, thus preventing the spread of fire. Additionally, the reinforcing fibers in FRP profiles also contribute to their fire resistance. Fiberglass, for example, is an inorganic material that does not burn. It acts as a barrier against heat transfer and helps to minimize the spread of flames. Furthermore, FRP pultrusion profiles can be engineered to meet specific fire safety standards and regulations. By incorporating additional fire retardant additives or using specialized resin systems, the fire resistance of these profiles can be further enhanced. It is important to note that while FRP pultrusion profiles are fire resistant, their exact fire rating may vary depending on the specific composition and design. Therefore, it is essential to consult with manufacturers or suppliers who can provide detailed information about the fire resistance properties of their FRP pultrusion profiles.

- Q: Are FRP pultrusion profiles resistant to graffiti?

- Yes, FRP pultrusion profiles are generally resistant to graffiti. The smooth surface of FRP profiles makes it difficult for graffiti to adhere, and any graffiti that is applied can be easily removed without causing damage to the profile.

- Q: Are FRP pultrusion profiles resistant to rotting or decaying?

- Yes, FRP pultrusion profiles are highly resistant to rotting or decaying. FRP, or fiber-reinforced polymer, is a composite material that consists of a polymer matrix reinforced with fibers. This combination makes FRP pultrusion profiles highly durable and resistant to environmental factors such as moisture, chemicals, and UV radiation, which can lead to rotting or decaying in other materials. Therefore, FRP pultrusion profiles are an excellent choice for applications where long-term resistance to rotting or decaying is required.

Send your message to us

FRP Pultrusion Profiles for Anti-Corrosion in Big Plants and Industries

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords